Medical applications and preparation methods of Pleurotus ferulae Lanzi polysaccharide and composites thereof

A technology of Pleurotus ferulae and polysaccharide, which is applied in the field of Pleurotus ferulae polysaccharide and pharmaceutical compositions containing Pleurotus ferulae polysaccharide, and can solve the problems of weakening anti-tumor immune response and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

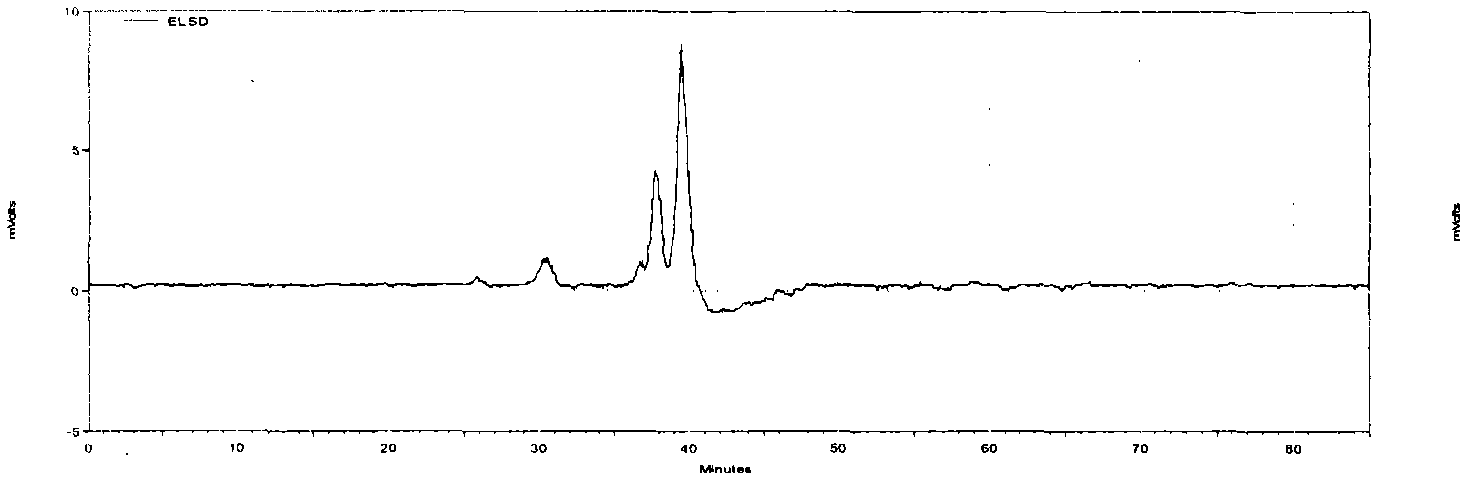

[0113] Example 1: Extraction and preparation of Pleurotus ferulai polysaccharide

[0114] Pleurotus ferulai (fresh) 20kg, cut into small pieces, add 400ml of water per 100g, squeeze the juice with a juicer for 1min, ultrasound for 30min, boil for 3h, cool, centrifuge to obtain the supernatant, filter paper suction. Precipitate and add 6 to be measured water to ultrasonic for 30min, boil for 1h, cool, centrifuge, take the supernatant, filter with filter paper, combine the supernatants and concentrate to obtain 9L of concentrate. The yield rate is 7.825%.

Embodiment 2

[0115] Example 2: Purification of Pleurotus ferulai polysaccharide

[0116] 50ml of Pleurotus ferulai concentrate prepared in Example 1 (equivalent to 50mg of raw material) was added with 0.6g of papain, adjusted to PH5-6, 60°C water bath for 1.5h, placed at room temperature, centrifuged at 3000r / min for 5min, took the supernatant and added Ethanol to 85% of the alcohol content, shake and place, centrifuge at 3000r / min for 5min, take the precipitate, repeat the operation 3 times, and obtain the purified Pleurotus ferulai polysaccharide.

Embodiment 3

[0117] Example 3: Investigation of papain enzymatic hydrolysis process

[0118] 1. Determination of the most suitable enzyme dosage:

[0119] Take 7 conical flasks with stoppers, add 20ml (43.5mg / ml) of Pleurotus ferulae extract to each flask, add papain (mass ratio of enzyme to substrate) 0mg / g, 2mg / g, 4mg / g, 6mg / g, 8mg / g, 10mg / g, 12mg / g, adjust PH6 with HCL, 50℃ water bath for 2h and then boiling water bath for 10min to inactivate the enzyme, cool to room temperature, centrifuge at 3000r / min for 5min, take the supernatant and add 95% Ethanol to alcohol concentration 80%, 3000r / min centrifugation for 10min to take the precipitate, wash the precipitate three times in the same way, and measure the yield of polysaccharide. The best enzyme base ratio is: 8mg / g.

[0120] Enzyme base ratio mg / g

[0121] 2. Determination of the optimal enzymolysis time:

[0122] Take 7 conical flasks with stoppers, add 20ml (43.5mg / ml) of Pleurotus ferulae extract to each bottle, add 6.96mg of papain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com