Barium strontium titanate-based superfine powder and preparation method thereof

A technology of strontium barium titanate and base powder, which is applied in the field of preparation of strontium barium titanate based ultrafine powder for ceramic capacitor materials, which can solve the problems of easy agglomeration of powder, reduction of uniformity of powder raw materials, and increase in particle size, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

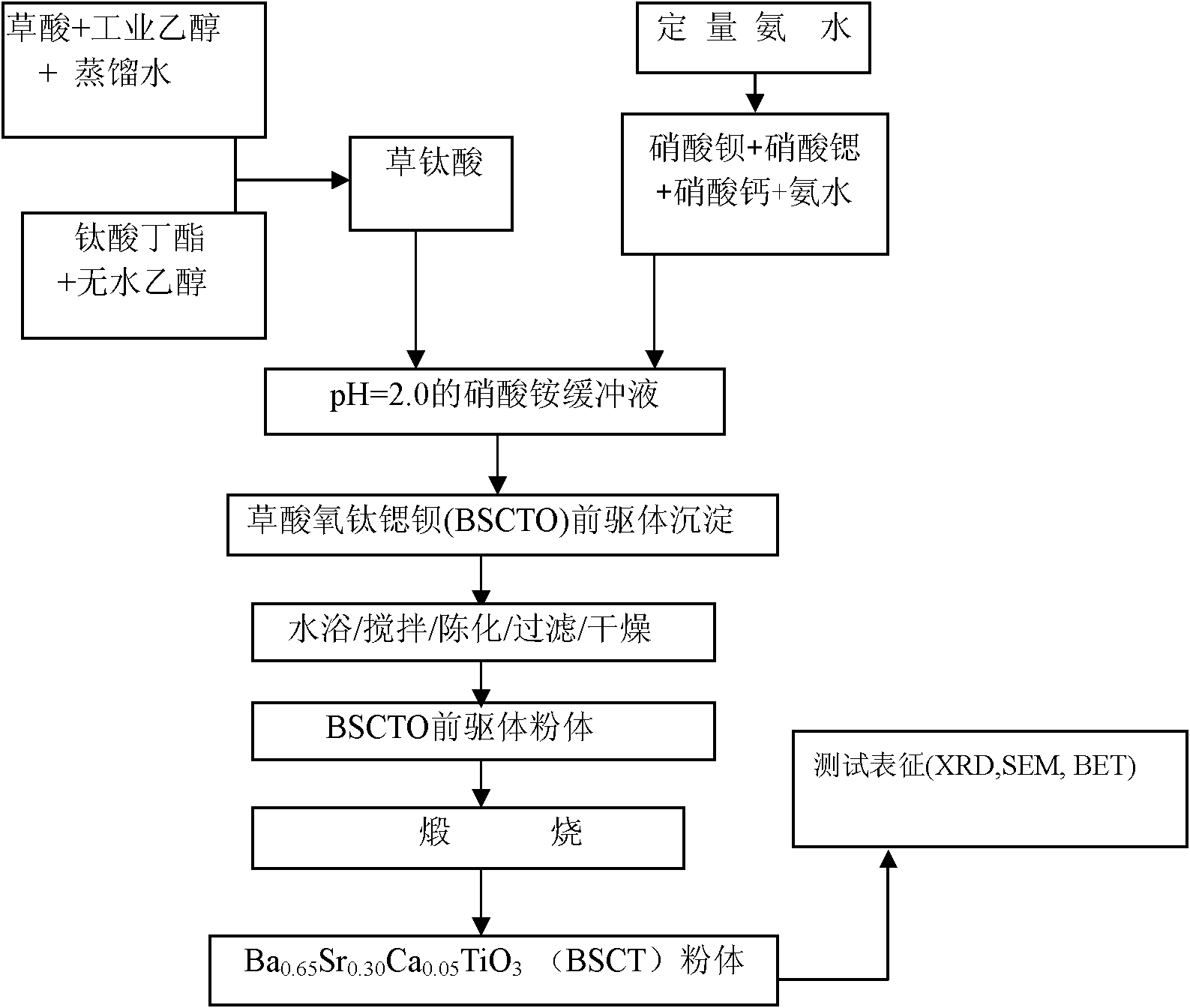

[0023] The experimental flow chart is as figure 1 shown. Press Ba 0.80 Sr 0.20 TiO 3 The stoichiometric ratio of Ba(NO 3 ) 2 , Sr(NO 3 ) 2 62.7216g, 12.1978g, added to deionized water, stirred vigorously and heated to 50°C to dissolve, added ammonia water to adjust the pH value to 2.0, and obtained a strontium barium salt solution with a concentration of 0.10mol / L. 20.0g NH 4 NO 3 Dissolve in 500ml deionized water with HNO 3 Adjust the pH value to 2.0, add 0.5wt% polyethylene glycol (PEG) as a dispersant, and prepare a 0.5mol / L ammonium nitrate buffer solution. Weigh 63.0280g of oxalic acid, 350ml each of absolute ethanol and deionized water, stir until dissolved, and prepare an oxalic acid solution with a concentration of 1.0mol / L. Add 102ml of butyl titanate to 500ml of absolute ethanol to prepare a 0.5mol / L butyl titanate ethanol solution, and stir evenly with a high-speed mixer. The prepared oxalic acid solution was added to the butyl titanate ethanol solution ...

Embodiment 2

[0026] The specific process is as example 1, the difference is that in the BST powder preparation process, according to Ba 0.60 Sr 0.40 TiO 3 The stoichiometric ratio of Ba(NO 3 ) 2 , Sr(NO 3 ) 2 They are 47.0412g and 25.3956g respectively, and after being dissolved in deionized water, ammonia water is added to adjust the pH value to 2.5 to obtain a strontium barium salt solution with a concentration of 0.20mol / L. 24.0g NH 4 NO 3 Dissolve in 500ml deionized water with HNO 3 The pH value was adjusted to 3.0, and 1.0 wt % polyethylene glycol (PEG) was added as a dispersant to prepare a 0.60 mol / L ammonium nitrate buffer solution. Weigh 75.6336g of oxalic acid, 350ml each of absolute ethanol and deionized water, stir until dissolved, and prepare an oxalic acid solution with a concentration of 1.2mol / L. Add 153ml of butyl titanate to 500ml of absolute ethanol to prepare a 0.70mol / L butyl titanate ethanol solution. Other processes in the middle are the same as Example 1. ...

Embodiment 3

[0028] The specific process is as example 1, the difference is that in the BST powder preparation process, according to Ba 0.20 Sr 0.80 TiO 3 The stoichiometric ratio of Ba(NO 3 ) 2 , Sr(NO 3 ) 2 They were 15.6804g and 50.7912g respectively, dissolved in deionized water and then added ammonia water to adjust the pH value to 3.0 to obtain a strontium barium calcium salt solution with a concentration of 0.30mol / L. 26.0g NH 4 NO 3 Dissolve in 500ml deionized water with HNO 3 Adjust the pH value to 3.5, add 1.5 wt% alkyl glycoside (APG) as a dispersant, and prepare a 0.65 mol / L ammonium nitrate buffer solution. Weigh 94.5420g of oxalic acid, 350ml each of absolute ethanol and deionized water, stir until dissolved, and prepare an oxalic acid solution with a concentration of 1.5mol / L. 187ml of butyl titanate was added to 500ml of absolute ethanol to prepare a 0.80mol / L butyl titanate ethanol solution. Other processes in the middle are the same as Example 1. After the titr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com