Method for synthesizing polyether amine

A synthesis method and polyetheramine technology are applied in the field of obtaining polyetheramine by selective hydrogenation of polyether nitrile, which can solve the problems of reducing brittleness and high toxicity, and achieve the effects of improving conversion rate, improving safety and reducing pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

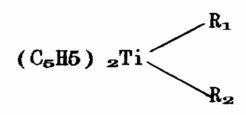

[0028] Add solvent and polyethernitrile into a 2L autoclave, reflux at the reflux temperature of the solvent, reduce the water in the solution to below 20mg / kg, replace the autoclave with nitrogen, and control the temperature of the autoclave at 60-120°C , add the main catalyst dicyclopentadiene titanium dichloride, the first co-catalyst, or the second co-catalyst, feed hydrogen, control the reaction pressure to 0.8-2.0 MPa, and react for 120 minutes to complete the hydrogenation reaction. The experimental results are shown in Table 1:

[0029]

Embodiment 10-13

[0030] Embodiment 10-13: The formula is the same as that of Embodiment 2, but the temperature and pressure are different. The data show that the method of the present invention is obviously superior to the prior art. The data show that the method of the present invention is obviously superior to the prior art.

[0031] Description A: Triisobutylaluminum;

[0032] B: n-butyllithium;

[0033] C: dibutyl magnesium;

[0034] D: n-butyllithium;

[0035] E: methyl benzoate;

[0036]F: Dimethyl phthalate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com