Ethylene vinyl acetate adhesive film and solar battery assembly

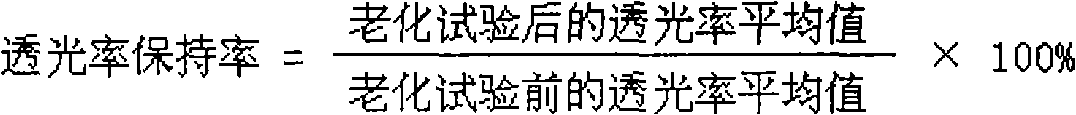

An ethylene vinyl acetate and copolymer technology, applied in electrical components, circuits, photovoltaic power generation, etc., can solve the problems of easy generation of bubbles, difficult to store, lack of glue, etc., and achieve good temperature resistance, packaging processability, and light transmittance. The effect of good retention rate, excellent moisture-heat aging resistance and UV aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of the EVA adhesive film of the present invention is not particularly limited, for example, the EVA copolymer and the fluorescent whitening agent (or the whitening masterbatch containing the fluorescent whitening agent) can be mixed uniformly together with other auxiliary agents, and then extruded and cast , Cooling, traction, coiling and other processes are processed into EVA film. In order to prevent EVA from cross-linking in advance, the processing temperature should not exceed 90°C. However, whitening masterbatches are preferred. If whitening masterbatches are used, whitening masterbatches can be pre-prepared before mixing. Take the preparation of whitening masterbatch with a concentration of 0.5% as an example, for example, in terms of parts by mass, add 0.5 parts of C.I. fluorescent whitening agent 393 [1533-45-5] (Zhejiang Chuanhua Huayang Chemical Co., Ltd. Whitening agent OB-1) and 100 parts of VA content 28% EVA copolymers (U.S. DuPont...

Embodiment

[0040] The EVA copolymers adopted in the following examples are all purchased from DuPont Company of the United States, the VA content is 28% by mass, and the melt index (MI) is 20-30 grams / 10 minutes (190 ° C, 2.16 kg), differential scanning calorimetry The melting point determined by (DSC) is greater than 70°C, and the Vicat softening point is greater than 42°C.

[0041] Preparation of whitening masterbatch

[0042] In terms of parts by mass, 0.5 parts of C.I. fluorescent whitening agent 393 [1533-45-5] (Zhejiang Chuanhua Huayang Chemical Co., Ltd., fluorescent whitening agent OB-1) and 100 parts of EVA with a VA content of 28% were copolymerized (U.S. DuPont Company) was fully mixed, and melted and extruded in a twin-screw extruder to obtain a whitening masterbatch with a concentration of 0.5%, which was used in the following examples.

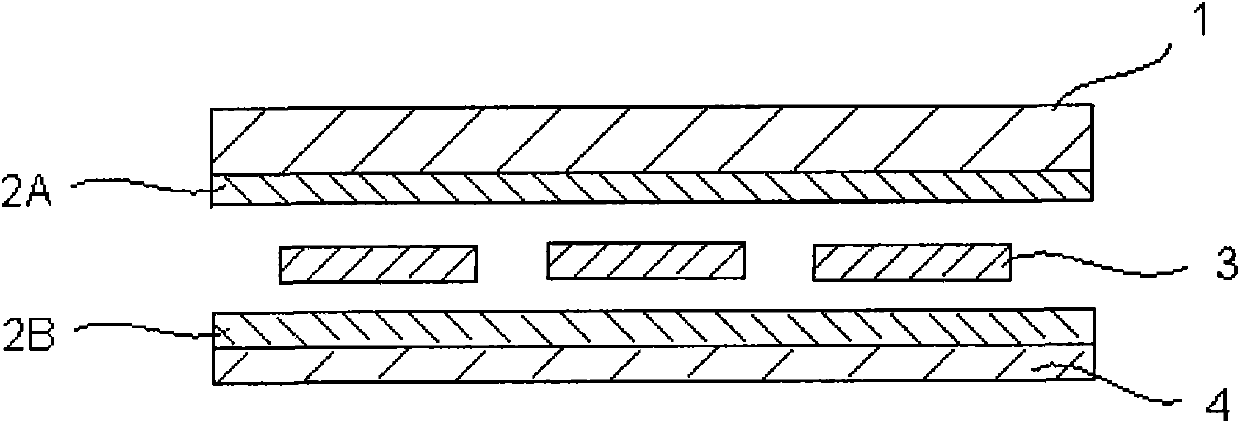

[0043] Preparation of solar cell modules

[0044] Use the EVA glue film of following embodiment to prepare solar cell module, as figure...

Embodiment 1

[0046] In 100 parts (parts by mass) of EVA copolymer (VA content 28%, U.S. DuPont), add 1 part of organic peroxide bis(tert-butylperoxyisopropyl) benzene (Akzo Nobel, Perkadox 14s-fl) , 0.5 parts of co-crosslinking agent trimethylolpropane triacrylate (Sartomer, SR351, USA), 0.5 parts of silane coupling agent γ-glycidyloxypropyl trimethoxysilane (Danyang Organic Silicon Material Industry Co., Ltd. , KH560), 0.1 part of UV absorber 2-hydroxyl-4-n-octyloxybenzophenone (Beijing Institute of Addition Auxiliaries, GW531), 0.1 part of light stabilizer bis(2,2,6,6 -Tetramethyl-4-piperidinyl) sebacate (Beijing Institute of Addition Auxiliaries, GW480) and 0.1 part of whitening masterbatch, mix all the raw materials evenly, add to a single-screw extruder and melt and extrude , the processing temperature should not exceed 90°C, and then through the processes of casting, cooling, pulling, coiling, etc., the EVA film S1 is obtained, and the thickness of the film is 0.6mm.

[0047] Gained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com