Green light luminescent material and preparation method thereof

A luminescent material and green light technology, applied in the field of green light emitting materials and their preparation, can solve the problems of high color temperature and low color rendering, and achieve the effects of high luminous intensity, high luminous efficiency and control of process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

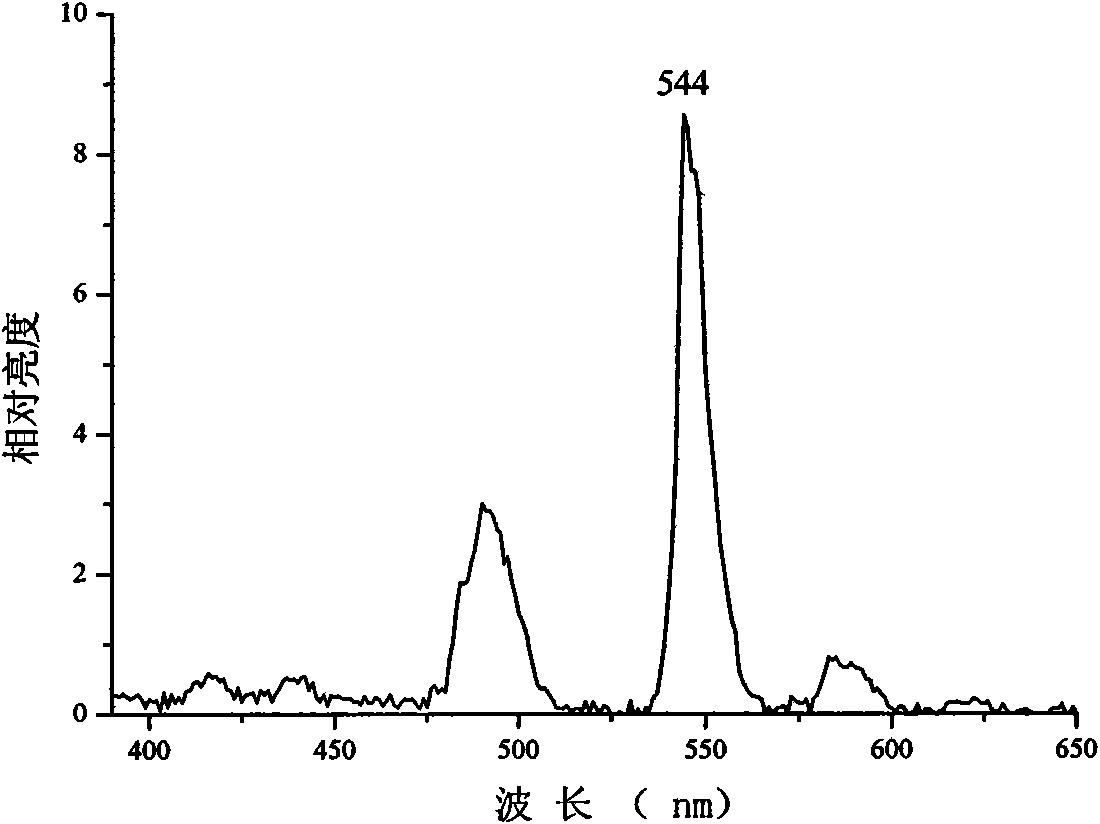

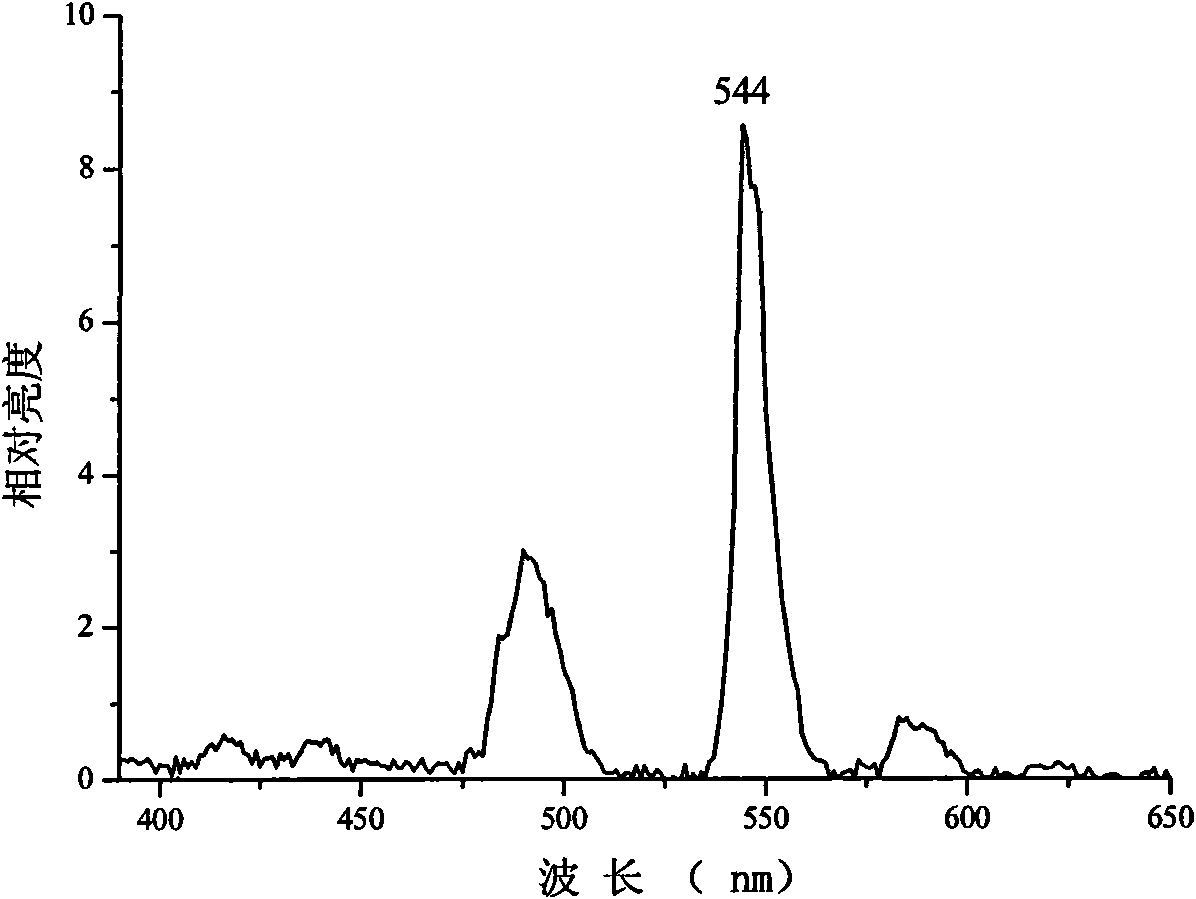

[0021] 0.4CaO 0.6Al 2 o 3 1.0 SiO2 2 : Preparation of 0.001Tb: Weigh calcium carbonate (CaCO 3 ) 0.4g, alumina (Al 2 o 3 ) 0.612g, silicon dioxide (SiO 2 ) 0.601g and terbium oxide (Tb 4 o 7 ) 0.00187g, put the weighed raw materials into a corundum crucible after grinding and mixing them evenly in an agate mortar, put the corundum crucible into a high-temperature box furnace, heat up to 1300°C and heat-preserve and calcinate for 12 hours, then cool to room temperature , to obtain the intermediate product, after grinding the intermediate product evenly, put it into the corundum crucible again, and then put the corundum crucible into the high temperature tube furnace, under 95% N 2 +5%H 2 Raise the temperature to 1300°C in a reducing atmosphere, heat-preserve and calcinate for 10 hours under this condition, then cool to room temperature, and grind the cooled product to obtain a green luminescent material added with rare earth element Tb. The green light-emitting materia...

Embodiment 2

[0023] 2.5CaO 1.0Al 2 o 3 1.0 SiO2 2 : Preparation of 0.5Tb: Weigh calcium oxide (CaO) 1.4g, aluminum oxide (Al 2 o 3 ) 1.02g, silicon dioxide (SiO 2 ) 0.601g and terbium oxide (Tb 4 o 7 ) 0.9346g, put the weighed raw materials into a corundum crucible after grinding and mixing them evenly in an agate mortar, put the corundum crucible into a high-temperature box furnace, heat up to 1400°C and heat-preserve for 20 hours, then cool to room temperature , to obtain an intermediate product, after grinding the intermediate product evenly, put it into a corundum crucible again, then put the corundum crucible into a high-temperature tube furnace, raise the temperature to 1000°C under H2 reducing atmosphere, and heat-preserve and calcinate under this condition for 20 hours, and then cooled to room temperature, and the cooled product was ground to obtain a green luminescent material added with rare earth element Tb. The green light-emitting material of this embodiment emits green...

Embodiment 3

[0025] 1.0CaO 0.5Al 2 o 3 1.0 SiO2 2 : Preparation of 0.1Tb: Weigh calcium carbonate (CaCO 3 ) 1.0g, alumina (Al 2 o 3 ) 0.51g, silicon dioxide (SiO 2 ) 0.601g and terbium oxide (Tb 4 o 7 ) 0.1869g, put the weighed raw materials into a corundum crucible after grinding and mixing them evenly in an agate mortar, then put the corundum crucible into a high-temperature box furnace, heat up to 1200°C and heat-preserve and calcinate for 12 hours, then cool to room temperature , to obtain the intermediate product, after grinding the intermediate product evenly, put it into the corundum crucible again, and then put the corundum crucible into the high temperature tube furnace, under 95% N 2 +5%H 2 Raise the temperature to 1200°C in a reducing atmosphere, heat-preserve and calcinate for 10 hours under this condition, then cool to room temperature, and grind the cooled product to obtain a green luminescent material added with rare earth element Tb. The green light-emitting materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com