PHBV (Poly (HydroxyButyrate-hydroxyValerate)) nano fiber support material as well as preparation method and application thereof

A scaffold material and nanofiber technology, applied in medical science, prosthesis, etc., can solve problems such as lack of mechanical properties of 3D structures, few successful examples of renewable scaffolds, lack of geometric complexity, etc., to achieve scaffold structure and fiber morphology Controllable, inexpensive, adhesion-promoting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

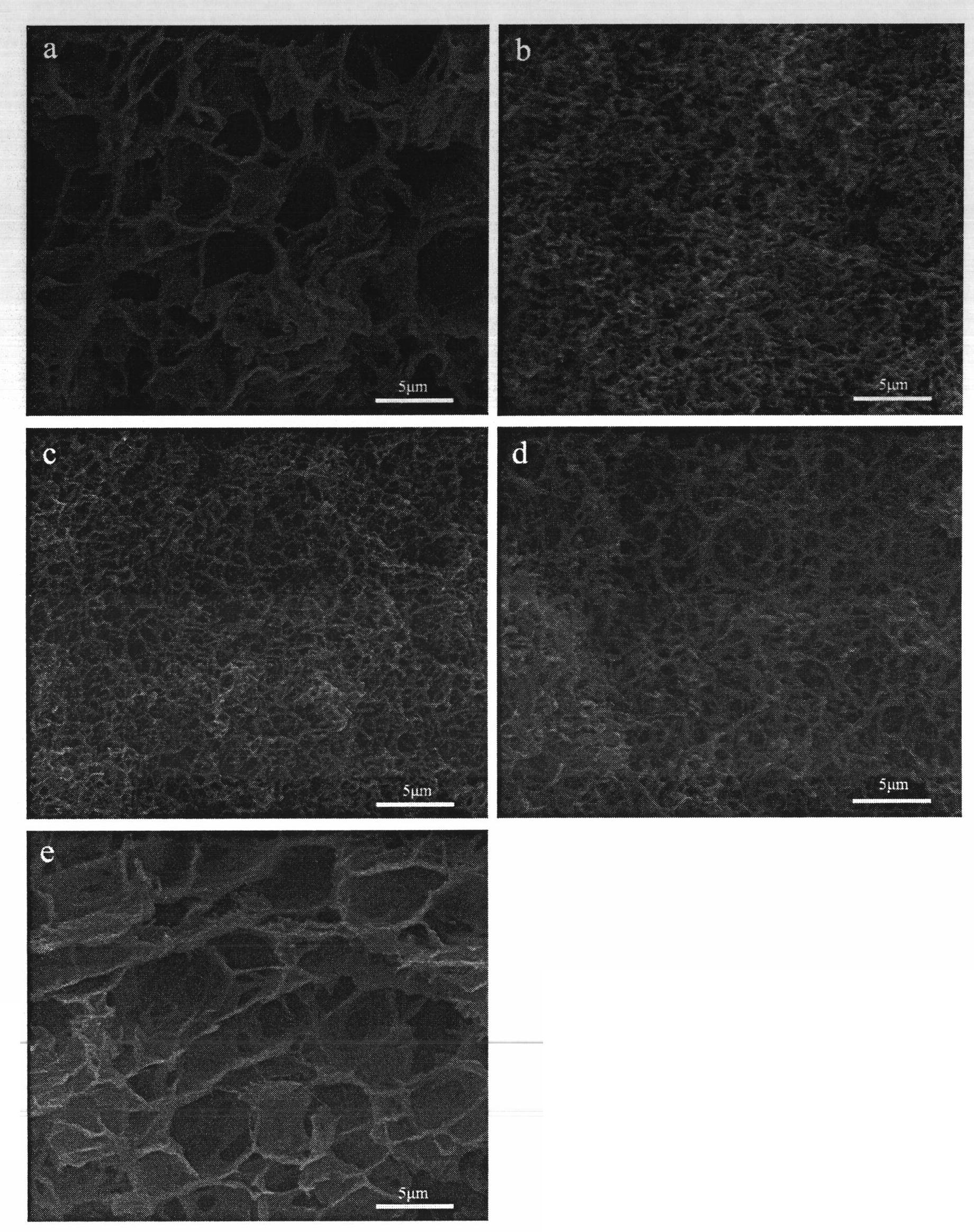

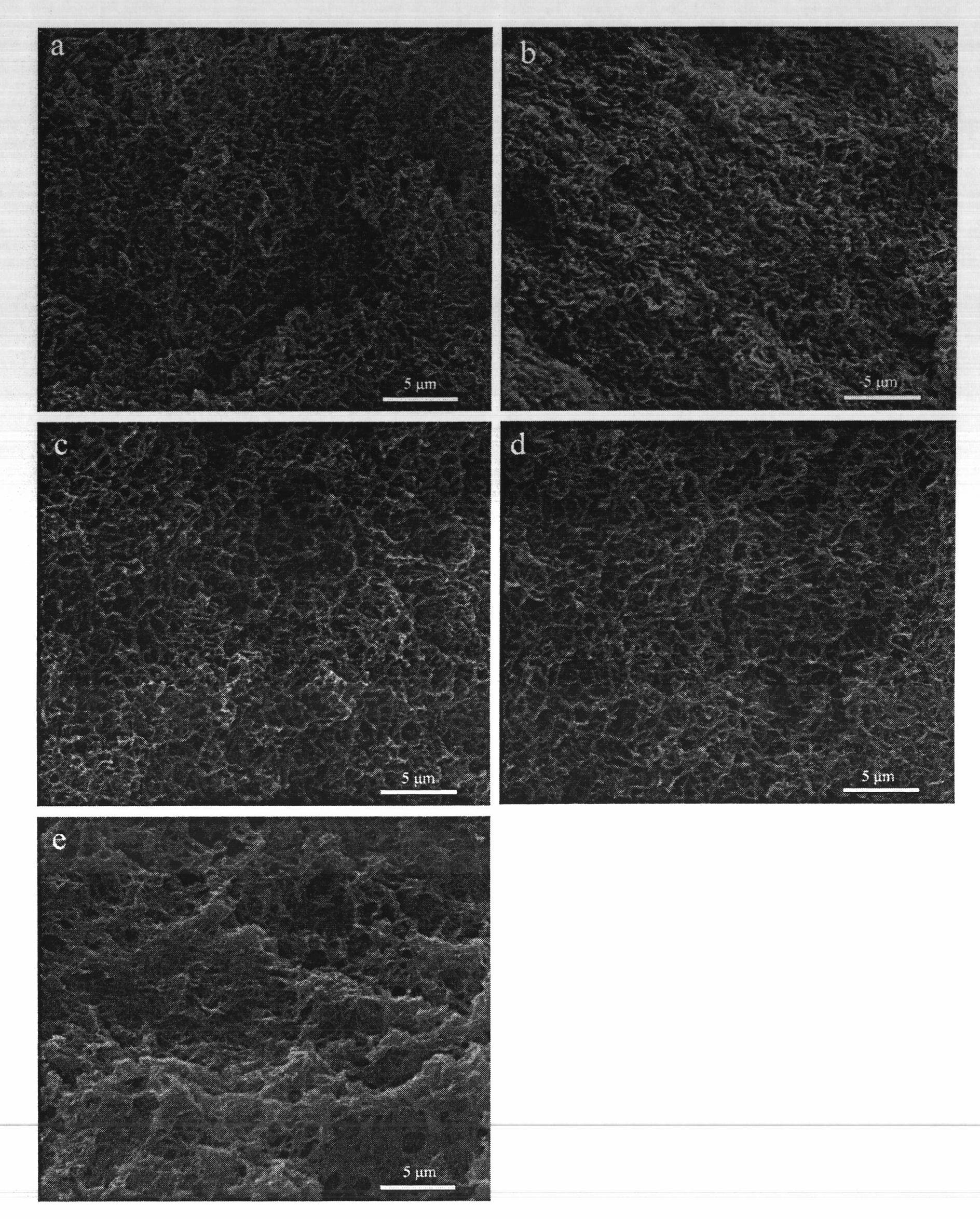

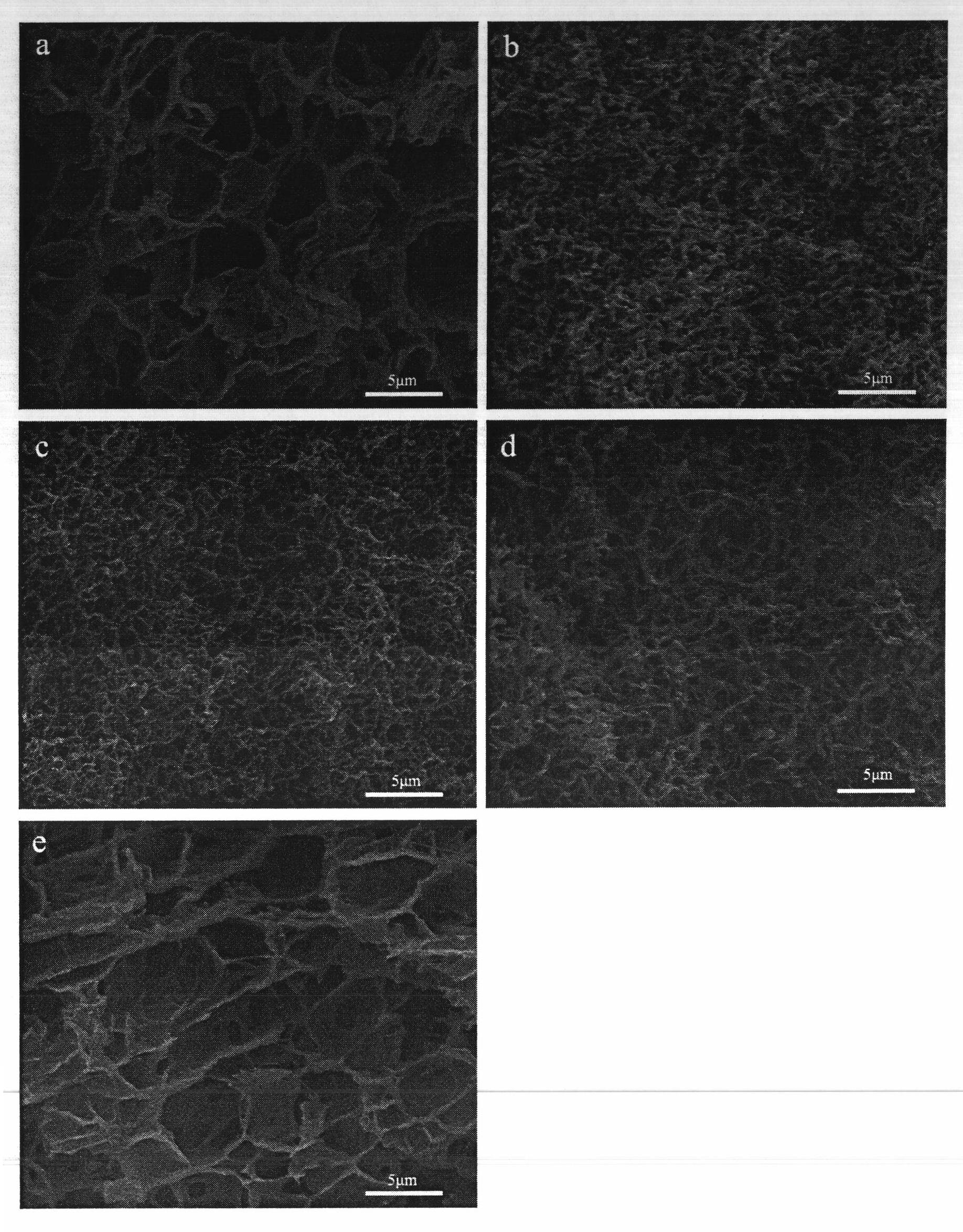

[0028] Chloroform: dioxane (9:1) solution to prepare PHBV pore-wall scaffolds ( figure 1 a)

[0029] Take the molecular weight as 3×10 5 Dissolve 0.225g of PHBV powder in 2.7ml chloroform solution, stir magnetically at 50°C for 3 hours, add 0.3ml dioxane solution, continue stirring for 2 hours, transfer to a 5ml beaker, seal with sealing glue, and place at -24°C Freeze in the refrigerator for 12 hours. Add acetone solution to replace the organic solvent, place in a 4°C refrigerator, change the acetone twice a day for 3 days; use deionized water to replace the acetone solution, place in a 4°C refrigerator, change the water twice a day, and replace for 3 days. Samples were freeze-dried at -80°C for 24 hours.

[0030] SEM image of PHBV scaffold ( figure 1 a) shows that it has a pore-wall structure, the thickness of the pore wall is 150-300 nm, and the pore diameter is 1.0-6.5 μm.

Embodiment 2

[0032] The PHBV sheet structure scaffold was prepared in chloroform:dioxane (8:2) solution ( figure 1 b)

[0033] Take the molecular weight as 3×10 5 Dissolve 0.225g of PHBV powder in 2.4ml chloroform solution, stir magnetically at 50°C for 3 hours, add 0.6ml dioxane solution, continue stirring for 2 hours, transfer to a 5ml beaker, seal with sealing glue, and place at -24°C Freeze in the refrigerator for 12 hours. Add acetone solution to replace the organic solvent, place in a 4°C refrigerator, change the acetone twice a day for 3 days; use deionized water to replace the acetone solution, place in a 4°C refrigerator, change the water twice a day, and replace for 3 days. Samples were freeze-dried at -80°C for 24 hours.

[0034] SEM image of PHBV scaffold ( figure 1 b) shows that it has a lamellar structure with a thickness of 60-120 nm and a pore size of 0.5-1.5 μm.

Embodiment 3

[0036] PHBV nanofibrous scaffolds were prepared in chloroform:dioxane (7:3) solution ( figure 1 c)

[0037] Take the molecular weight as 3×10 5 Dissolve 0.225g of PHBV powder in 2.1ml of chloroform solution, stir magnetically at 50°C for 3 hours, add 0.9ml of dioxane solution, continue stirring for 2 hours, transfer to a 5ml beaker, seal with sealing glue, and place at -24°C Freeze in the refrigerator for 12 hours. Add acetone solution to replace the organic solvent, place in a 4°C refrigerator, change the acetone twice a day for 3 days; use deionized water to replace the acetone solution, place in a 4°C refrigerator, change the water twice a day, and replace for 3 days. Samples were freeze-dried at -80°C for 24 hours.

[0038] SEM image of PHBV scaffold ( figure 1 c) shows that it is a nanofiber structure, the diameter of the nanofiber is 40-100 nm, and the pore size is 0.3-1.0 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com