Super-light aggregate concrete for long-distance homogeneous pumping construction and preparation method thereof

A lightweight aggregate concrete, long-distance technology, applied in the field of concrete, can solve the problems of reduced concrete volume, reduced work performance, loss of concrete strength, etc., to alleviate delamination and segregation, good work performance and homogeneity, increase The effect of buoyancy resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

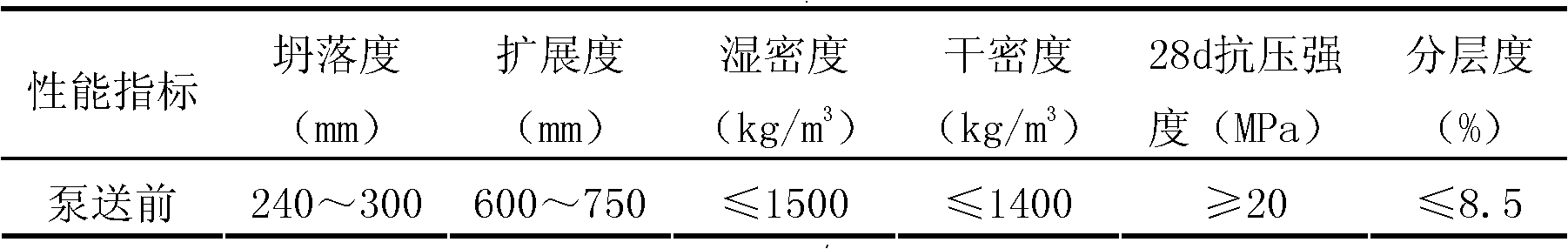

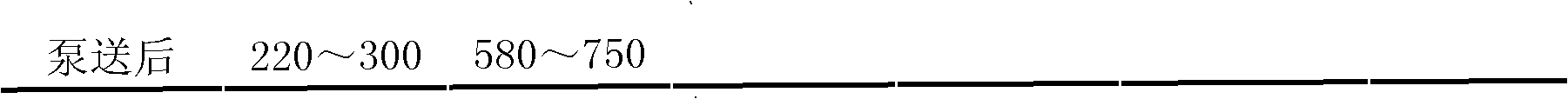

[0036] The proportion of ultra-light aggregate concrete used for long-distance homogeneous pumping construction is shown in Table 2.

[0037] Table 2 Proportion of ultra-light aggregate concrete (kg / m 3 )

[0038]

[0039] Described cement is P.O42.5 cement (Huaxin PO42.5 cement);

[0040] The fly ash is Class I fly ash, and the water demand ratio is less than 95wt%;

[0041] The ultra-light ceramsite has a bulk density of 200-500kg / m 3Between the shale ceramsite, particle size is 5 ~ 20mm;

[0042] The ceramsite is obtained by crushing ultra-light ceramsite, and the fineness modulus is 2.5-2.8;

[0043] The pumping agent is lignocellulose;

[0044] The water reducer is polycarboxylate water reducer (JM-VIII type polycarboxylate water reducer of Jiangsu Academy of Building Research).

[0045] The preparation method of the above-mentioned ultra-light aggregate concrete for long-distance homogeneous pumping construction, it includes the following steps:

[0046] 1) Acc...

Embodiment 2

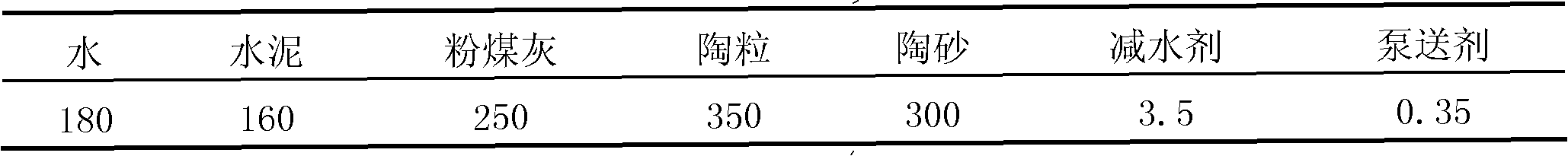

[0055] The proportion of ultra-light aggregate concrete used for long-distance homogeneous pumping construction is shown in Table 4.

[0056] Table 4 Proportion of ultra-light aggregate concrete (kg / m 3 )

[0057]

[0058] Described cement is P.O42.5 cement (Yadong PO42.5 cement);

[0059] The fly ash is Class I fly ash, and the water demand ratio is less than 95wt%;

[0060] The ultra-light ceramsite has a bulk density of 200-500kg / m 3 Between the fly ash ceramsite, the particle size is 5 ~ 20mm;

[0061] The ceramsite is obtained by crushing ultra-light ceramsite, and the fineness modulus is 2.5-2.8;

[0062] The pumping agent is hydroxypropyl methylcellulose ether;

[0063] The water reducer is a polycarboxylate water reducer (the water reducer is Shanghai Sanrui VIVID-500 polycarboxylate superplasticizer).

[0064] The preparation method of the above-mentioned ultra-light aggregate concrete for long-distance homogeneous pumping construction, it includes the follow...

Embodiment 3

[0074] The proportion of ultra-light aggregate concrete used for long-distance homogeneous pumping construction is shown in Table 6.

[0075] Table 6 Proportion of ultra-light aggregate concrete (kg / m 3 )

[0076]

[0077] Described cement is P.O.42.5 cement;

[0078] The fly ash is Class I fly ash, and the water demand ratio is less than 95wt%;

[0079] The ultra-light ceramsite has a bulk density of 200-500kg / m 3 Between the sludge ceramsite, the particle size is 5 ~ 20mm;

[0080] The ceramsite is obtained by crushing ultra-light ceramsite, and the fineness modulus is 2.5-2.8;

[0081] The pumping agent is lignocellulose;

[0082] The water reducer is the JM-VIII type polycarboxylate water reducer of Jiangsu Academy of Building Research.

[0083] The preparation method of the above-mentioned ultra-light aggregate concrete for long-distance homogeneous pumping construction, it includes the following steps:

[0084] 1) According to the proportion of ultra-light aggr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com