Preparation method of 1-N-ethyl gentamicin Cla

A technology of ethyl gentamycin and ethyl gentamycin, which is applied in the field of preparation of medicinal raw materials, can solve the problems of low yield, avoid side reactions of alkylation, enhance polarization, and avoid hydrolysis Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

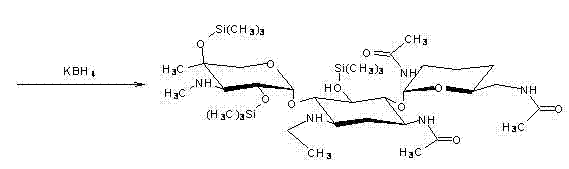

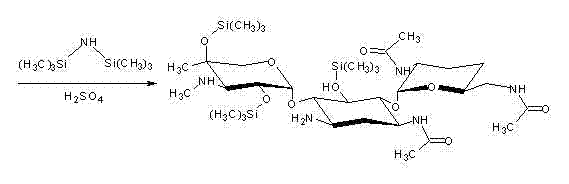

[0028] ①Add 100mL of chloroform solvent, 20mL of 0.104mol hexamethyldisilazane and 0.05mL of catalytic concentrated sulfuric acid (98wt%) into the dried three-necked flask with reflux device, and then add 15g 0.026mol of 3,2',6'-tris-N-acetyl gentamicin C 1a (Ⅰ), heating to reflux and generating 3,2',6'-tris-N-acetyl-5,2”,4”-tris(trimethylsilyl)gentamicin C 1a (II) The silanization reaction, until the reaction is complete, the heating reflux time is 5h. Then, evaporate the chloroform solvent to obtain 3,2',6'-tris-N-acetyl-5,2”,4”-tris(trimethylsilyl)gentamicin C 1a (II).

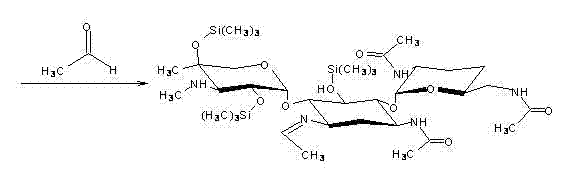

[0029] ②Cool the system of step ① to 20℃~25℃, add 100mL of dichloromethane, continue to cool down to 10℃, add 1.5mL of acetaldehyde, and generate 3,2',6'-tri-N- under stirring Acetyl-5,2”,4”-tris(trimethylsilyl)ethylimine gentamicin C 1a (Ⅲ) N-alkylation reaction for 1h. Then add 20mL of boric acid buffer with a pH of 9~10 (the boric acid buffer is composed of 0.6g of boric acid, 15mL of water and 5ml of NaOH...

Embodiment 2~ Embodiment 8)

[0033] The preparation method of each embodiment is basically the same as that of embodiment 1, the difference is: the hexamethyldisilazane used in step ① and 3,2',6'-tri-N-acetylgentamicin C 1a The molar ratio of, the molar ratio of each embodiment and the effect on the reaction are shown in Table 1.

[0034] Table 1

[0035] Hexamethyldisilazane and 3,2',6'-tris-N-acetyl gentamicin C 1a Molar ratio 3,2',6'-tris-N-acetyl gentamicin C 1a Conversion rate Example 1 4.0:1 70.2% Example 2 1.5:1 43.8% Example 3 2:1 48.5% Example 4 2.5:1 53.2% Example 5 3:1 60.1% Example 6 3.5:1 69.7% Example 7 4.5:1 69.9% Example 8 5:1 68.4%

[0036] Theoretically, 1mol of hexamethyldisilazane can silylate 2mol of alcoholic hydroxyl groups, and every molecule of 3,2',6'-tri-N-acetylgentamycin C 1a There are 3 alcoholic hydroxyl groups, therefore, hexamethyldisilazane and 3,2',6'-tris-N-acetyl gentamicin C 1a The theoretical molar ratio is 1.5:1. However, it can be seen from Table 1 that the t...

Embodiment 9~ Embodiment 12)

[0038] The preparation method of each embodiment is basically the same as that of embodiment 1, except that: the acetaldehyde used in step ② is the same as the 3,2',6'-tris-N-acetylgentamicin C used in step ① 1a The molar ratio of, the molar ratio of each embodiment and the effect on the reaction are shown in Table 2.

[0039] Table 2

[0040] Acetaldehyde and 3,2',6'-tris-N-acetyl gentamicin C 1a Molar ratio 3,2',6'-tris-N-acetyl gentamicin C 1a Conversion rate ETM-1 ETM-2 Example 1 1:1 70.2% 0.7% 1.5% Example 9 0.8:1 65.4% 0.4% 1.0% Example 10 1.2:1 70.3% 3.1% 8.2% Example 11 1.5:1 68.5% 4.2% 10.1% Example 12 2:1 69.5% 4.3% 13.4%

[0041] It can be seen from Table 2 that increasing the amount of acetaldehyde, although the conversion rate is slightly improved, but the two side reaction products ETM-1 (3"-N-ethyl gentamicin C 1a ) And ETM-2 (1,3”-di-N-ethyl gentamicin C 1a ) Is also significantly increased, and these two side reaction products are difficult to remove in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com