Vacuum residue processing method

A vacuum residue and wax oil technology, applied in the field of petroleum refining, can solve the problems of heavy oil, high coke yield, product distribution inferior to wax oil catalytic cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

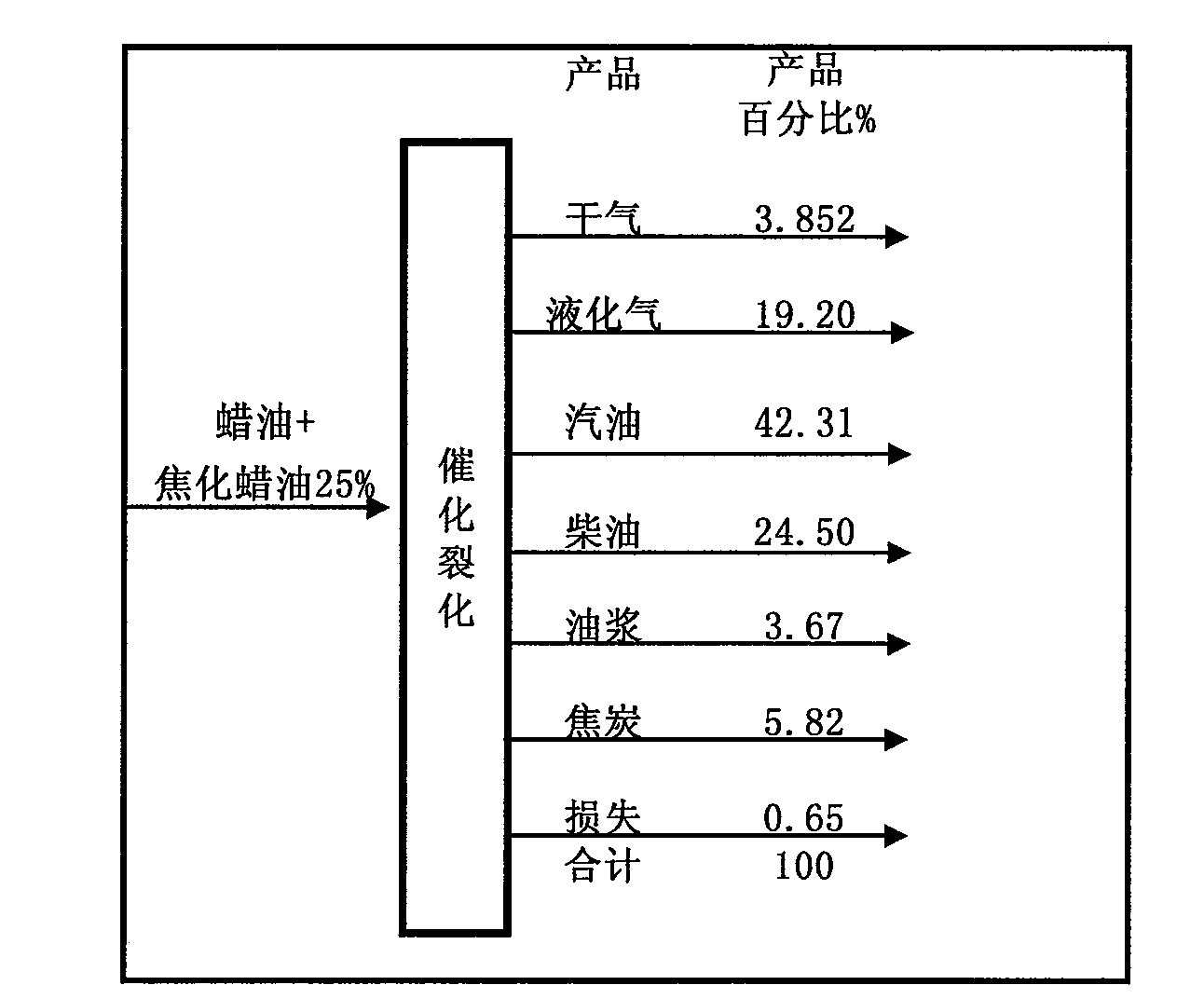

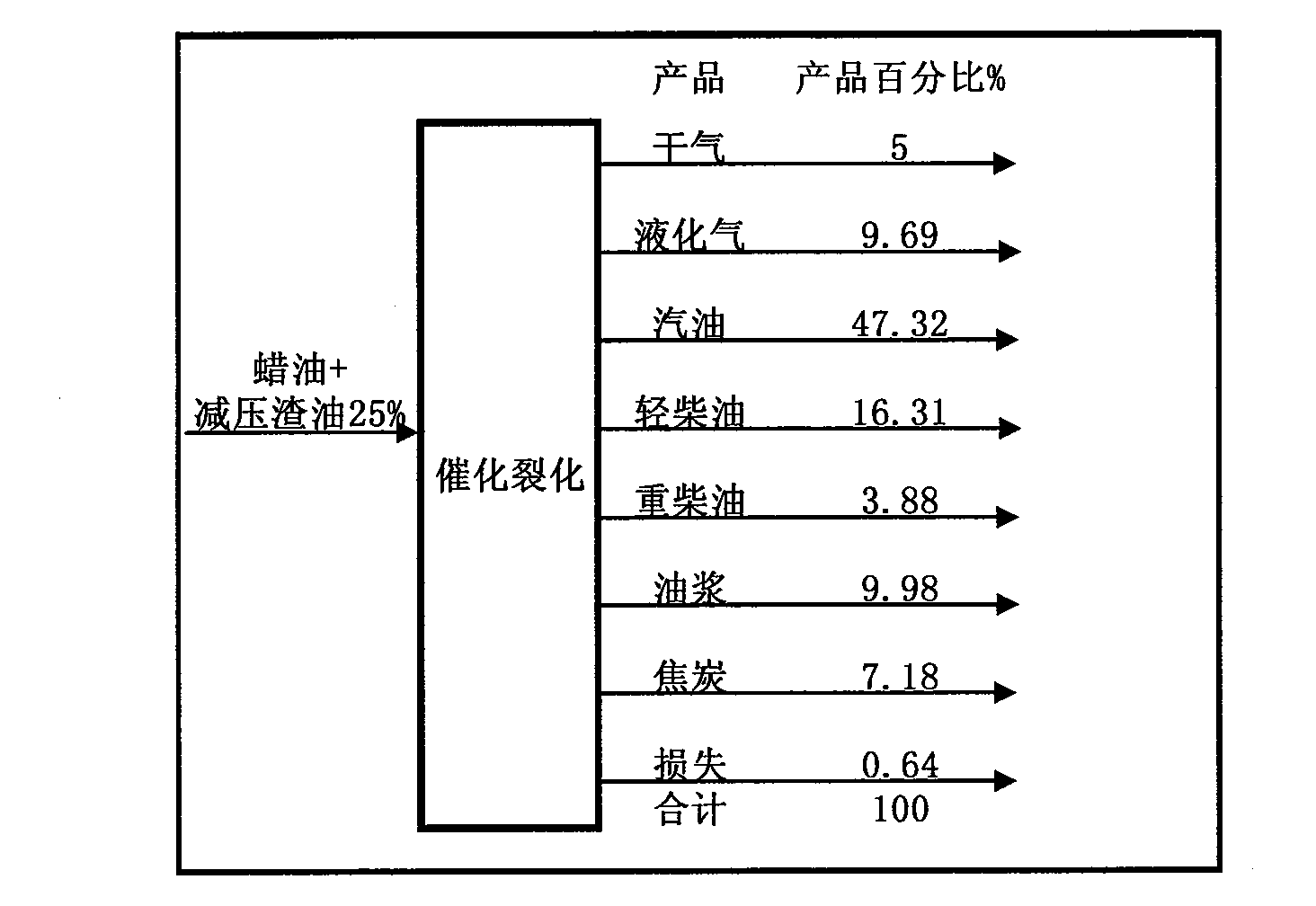

[0026] Using Shengli crude oil as raw material, the vacuum residue is fed into the delayed coking unit. The coking process conditions are: the circulation ratio is 0, the furnace outlet temperature is 500°C, and the coke tower top pressure is 0.16MPa to obtain dry gas, liquefied petroleum gas, gasoline, and diesel oil. , Wax oil, coke products. Blend straight-run wax oil with 25% vacuum residue into the catalytic cracking unit. The catalytic cracking process conditions are: reaction temperature 500°C, reaction pressure 0.1373MPa, agent-to-oil ratio 5, to obtain dry gas, liquefied gas, gasoline, diesel, Oil slurry, coke products. The percentage distribution of each product of catalytic cracking is as follows Figure 4 shown. Blend straight-run wax oil with 16% coker wax oil into the catalytic cracking unit. The catalytic cracking process conditions are: reaction temperature 500°C, reaction pressure 0.1373MPa, agent-to-oil ratio 5, to obtain dry gas, liquefied gas, gasoline, d...

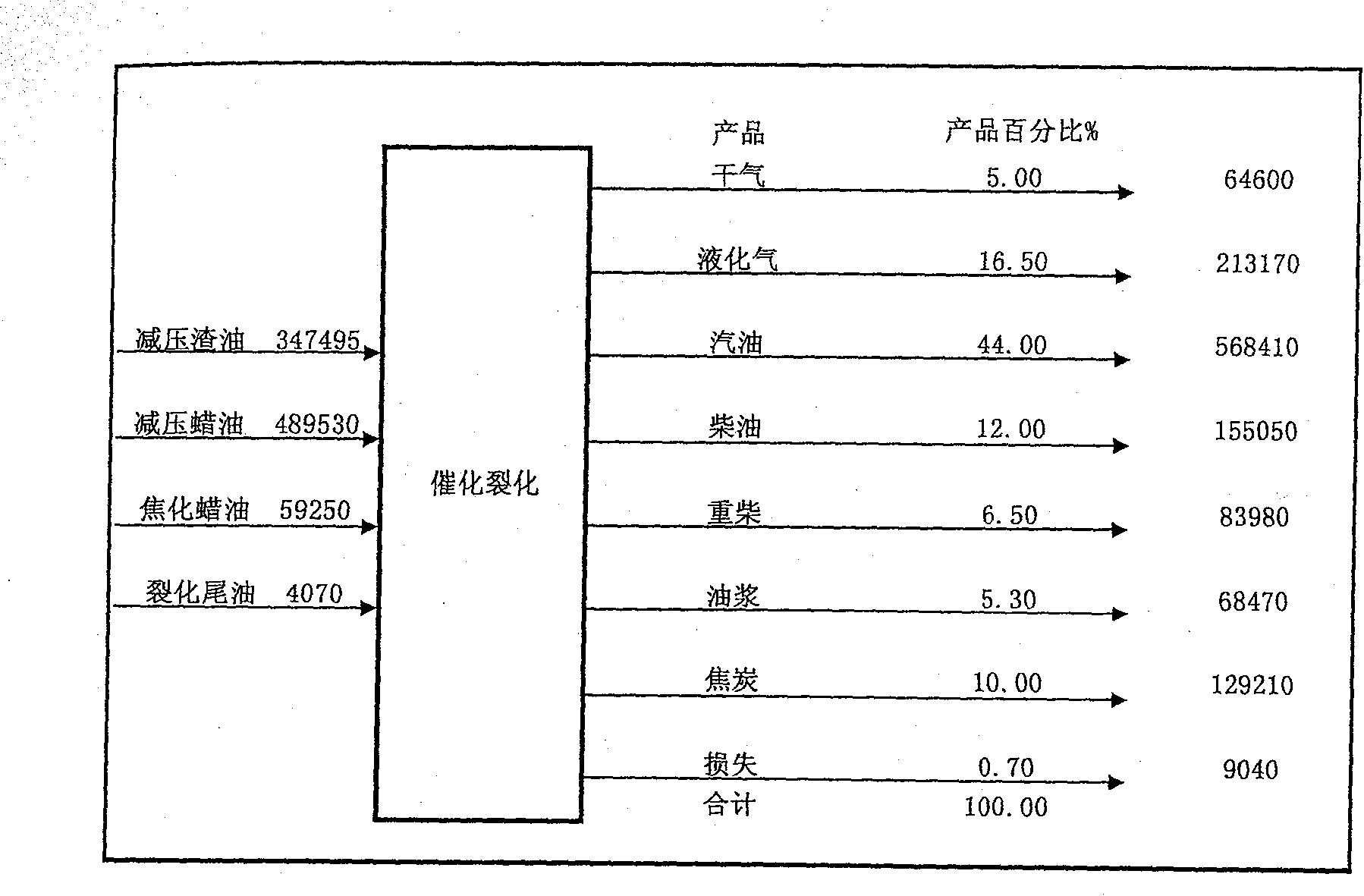

example 4

[0034] The catalytic cracking catalyst used in the test was collected from the upper balancer of the heavy catalyst unit of Wuhan Branch; the coker wax oil was also collected from the coking unit of Wuhan Branch and refined; the raw material of the coking unit came from the decompression of 15% Cabinda oil blended with mixed crude oil in Yizheng residual oil. Straight-run wax oil comes from the atmospheric and vacuum unit in Yizheng where mixed crude oil is blended with 15% Cabinda oil. The experimental device used in the catalytic cracking medium-scale reaction test is the XTL-5 type high and low parallel riser catalytic cracking test device, manufactured by the Refining Research Institute of Sinopec Luoyang Petrochemical Engineering Company. Considering that it is impossible for industrial catalytic cracking units to use coker gas oil alone as the raw material for catalytic cracking, the ratio of normal bottom heavy oil for oil transportation in Yizheng pipeline is generally...

example 5

[0039] The coking reaction test equipment is a tubular coking test device, and the coking reaction tube is equivalent to the heating furnace and coke tower of the factory. Under the condition of normal pressure, the temperature of the constant reaction tube is divided into upper, middle and lower sections, and the reaction temperature is set according to the needs of the test. The positive and negative deviation of the temperature of each reaction point is less than 3°C. The constant feed rate was 200mL / h, and the feed time was 2.5h. After the feed was stopped, the reaction temperature was maintained and nitrogen was purged for 0.5h.

[0040] The coking reaction of fresh raw materials (0 circulation ratio) at different reaction temperatures of the test device, the test results are shown in Table 5-1.

[0041] Table 5-1 Yield of coking reaction products at different reaction temperatures

[0042]

[0043] It can be seen from Table 5-1 that the coking reaction temperature de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com