Method for manufacturing intermediate P-type electrode of tunable resonant cavity enhanced detector

An enhanced and detector technology, which is applied in the manufacture of microstructure devices, techniques for producing decorative surface effects, decorative arts, etc., can solve the problems of reduced corrosion selection ratio, difficult corrosion process, and increased production costs, to achieve Improve the corrosion selection ratio, reduce the difficulty and cost of the process, and improve the effect of P-type electrode contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

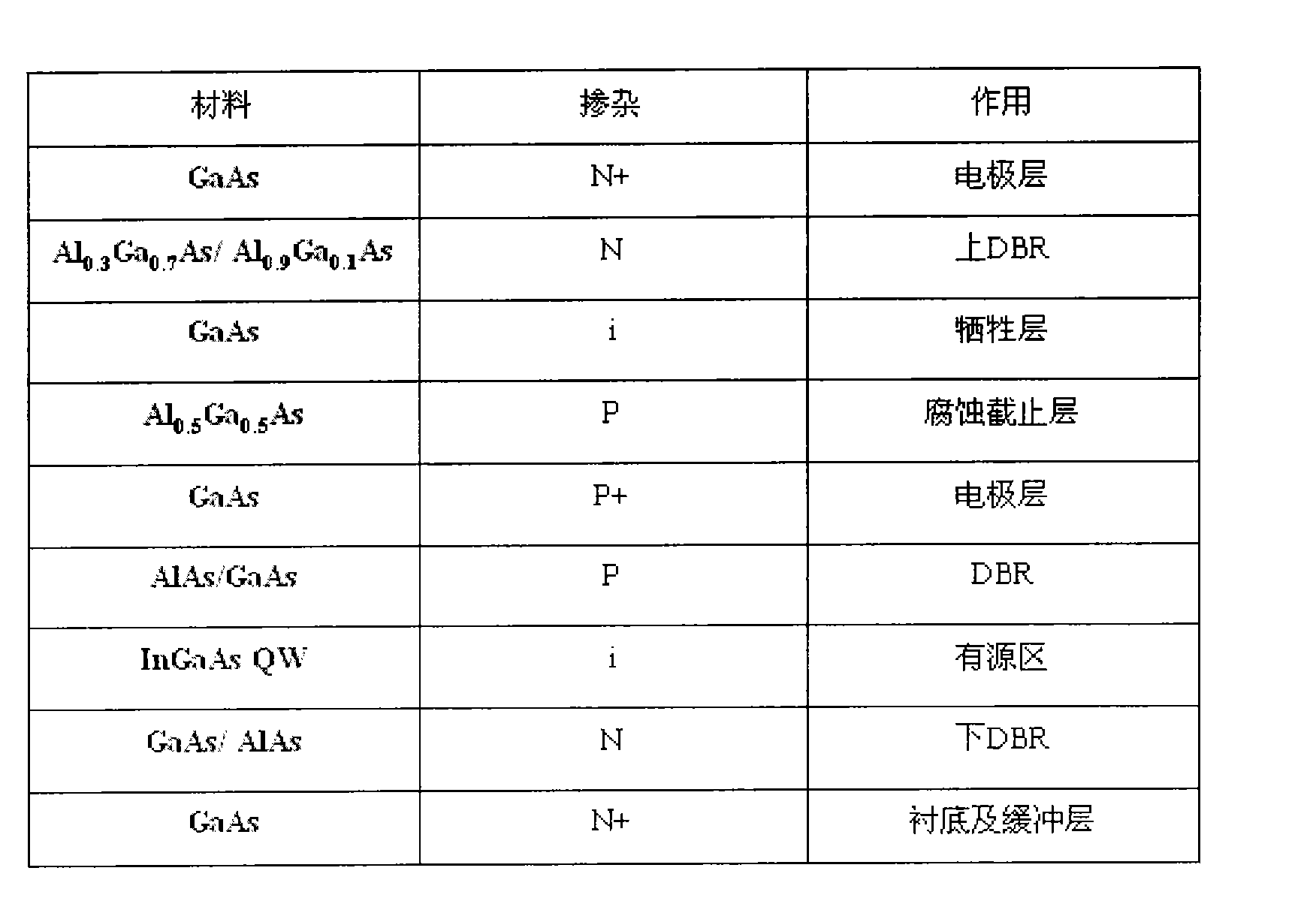

[0036] In the present invention, by rationally designing the material structure of the epitaxial wafer, the electrode contact layer is placed under the corrosion cut-off layer, and the corrosion cut-off layer adopts Al with a larger corrosion selection ratio. 0.5 Ga 0.5 As material, the electrode contact layer is made of GaAs material that can obtain higher P-type doping, and with two selective etching solutions, it solves the problem of making the intermediate P-type electrode.

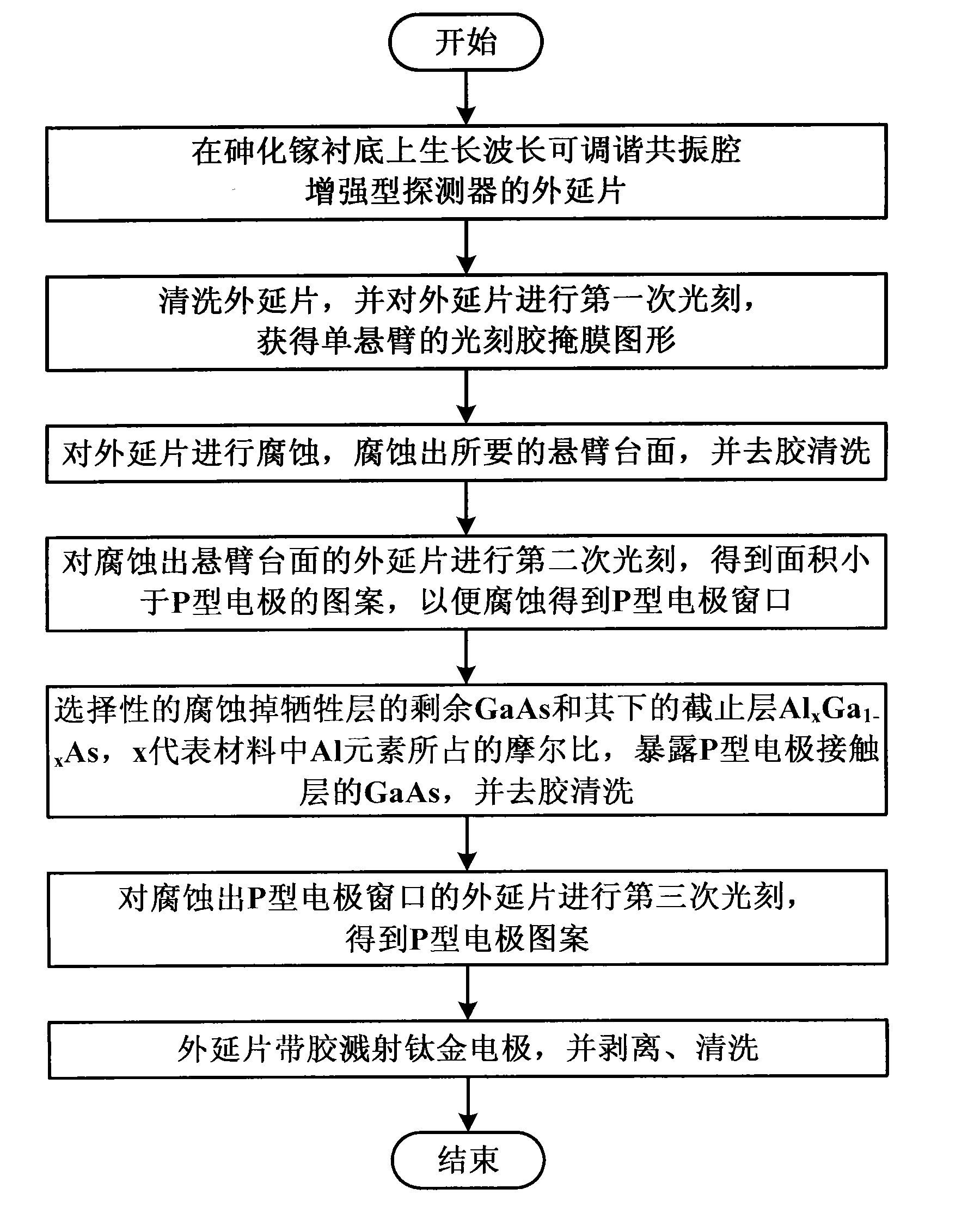

[0037] like figure 1 as shown, figure 1 It is a flowchart of a method for making a P-type electrode in the middle of a tunable resonant cavity enhanced detector provided by the present invention, and the method includes:

[0038] A. Growth of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com