ZSM-5 zeolite and synthesis method thereof

A technology of ZSM-5 and synthesis method, which is applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problem that ZSM-5 zeolite does not contain mesopores, and achieve good propylene selection high efficiency, low production cost and low yield of heavy oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation of seed crystal solution: Add 15 grams of sodium hydroxide to 310 grams of water, dissolve and make it transparent, then add 10 grams of ZSM-5 zeolite, heat to 80°C, stir for 30 minutes, replenish the water evaporated during the heating process, and obtain a crystal seed solution. Seed liquid.

[0028] Add 25 grams of sodium aluminate into 500 grams of water, dissolve and make it transparent, then add 194 grams of coarse-porous silica gel, then add seed liquid, and stir for 30 minutes to obtain a gel. The gel was transferred to a 2-liter stainless steel crystallization kettle, sealed and then dynamically crystallized at 160° C. for 30 hours with a stirring speed of 100 rpm. After suction filtration, washing and drying, a solid product was obtained. The solid product was analyzed by X-ray diffraction to be a pure phase ZSM-5 zeolite with a relative crystallinity of 102%. In the present embodiment, the mol ratio between each component of reaction mixture is a...

Embodiment 2

[0030] Preparation of seed crystal liquid: 29.6 g of NaY zeolite was added to 320 g of water, and treated for 3 minutes under the action of ultrasonic waves (frequency of ultrasonic wave was 28KHz, ultrasonic power 100w) to obtain seed crystal liquid.

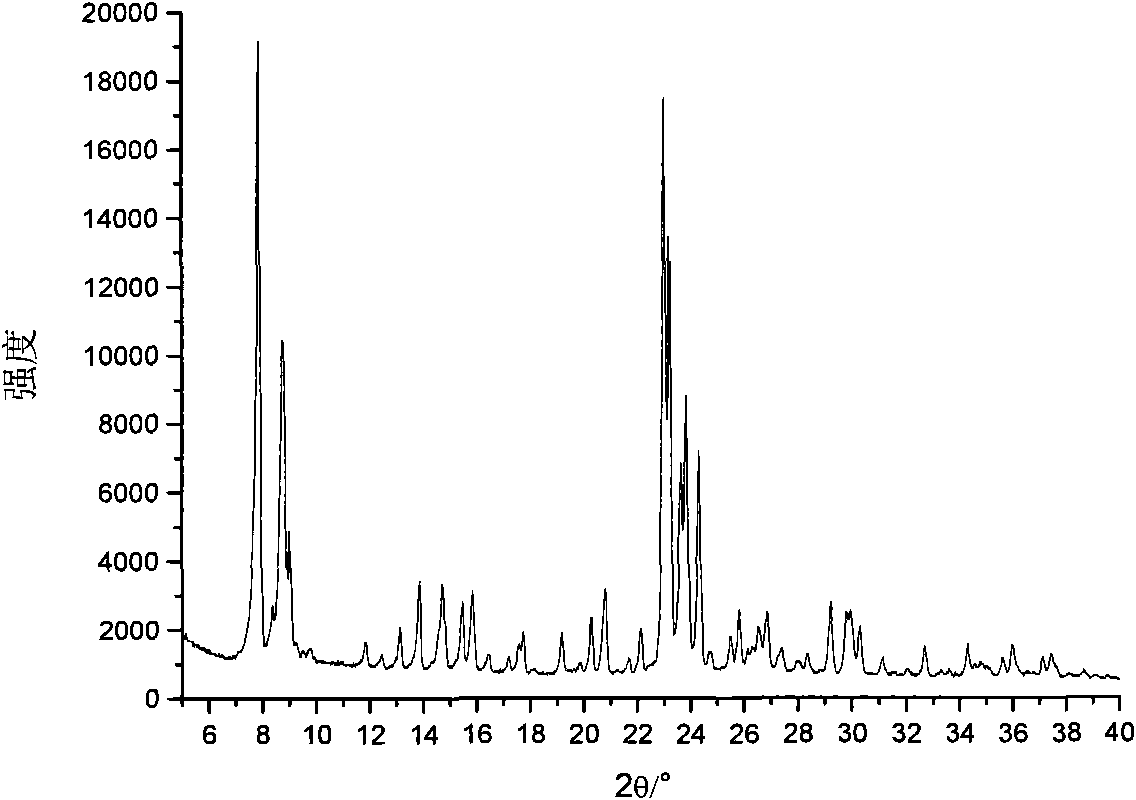

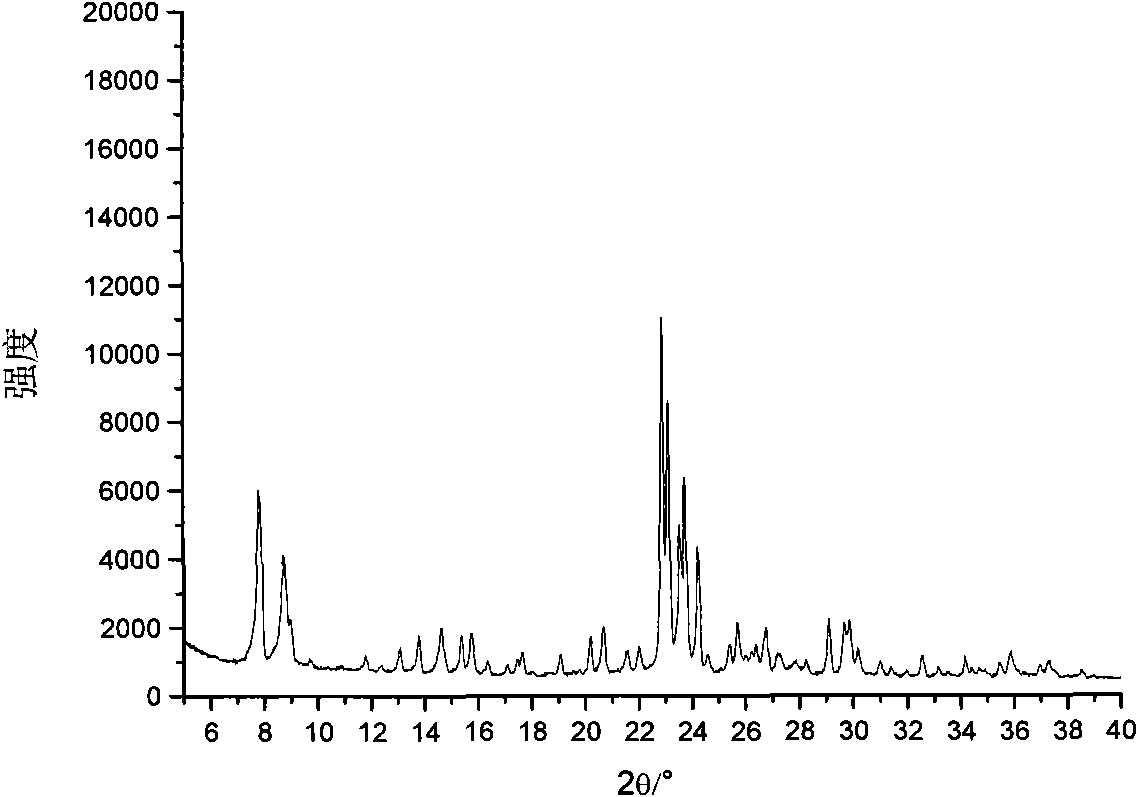

[0031] Add 10.4 grams of sodium aluminate and 23.3 grams of sodium hydroxide to 400 grams of water. After dissolving and making it transparent, add 243 grams of coarse-pore silica gel, then add the seed liquid, and stir for 30 minutes to obtain a uniform gel. The gel was transferred to a 2-liter stainless steel crystallization kettle, sealed and then dynamically crystallized at 180° C. for 16 hours at a dynamic crystallization stirring speed of 100 rpm. The solid product was obtained after suction filtration, washing, and drying. The solid product is analyzed by X-ray diffraction to be a pure phase ZSM-5 zeolite (see figure 1), the relative crystallinity is 104%. In the present embodiment, the molar ratio between each componen...

Embodiment 3

[0033] Seed liquid preparation: Add 26.2 grams of sodium hydroxide to 320 grams of water, dissolve and make it transparent, then add 18.5 grams of ZSM-5 zeolite, transfer to a 1-liter stainless steel crystallization kettle, seal it and stir at 120°C for 30 minutes, then cool , to obtain the seed liquid.

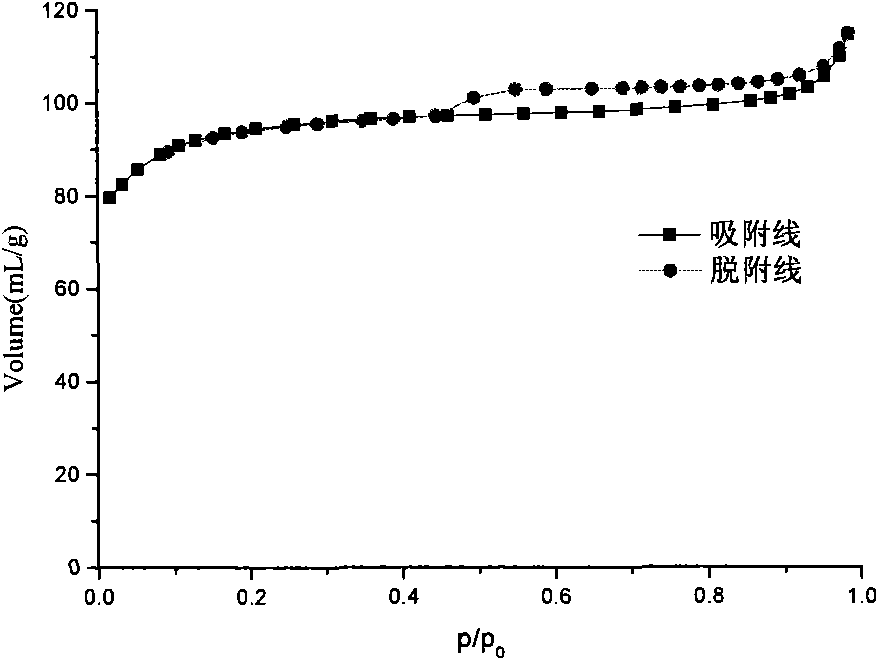

[0034] Add 23.8 grams of sodium aluminate into 400 grams of water, dissolve and make it transparent, then add 369 grams of coarse-porous silica gel, then add the seed liquid, and stir for 30 minutes to obtain a uniform gel. The gel was transferred to a 2-liter stainless steel crystallization kettle, sealed and dynamically crystallized at 190° C. for 10 hours at a dynamic crystallization stirring speed of 100 rpm. After suction filtration, washing, and drying, a solid product was obtained. The solid product is analyzed by X-ray diffraction to be a pure phase ZSM-5 zeolite (see attached figure 1 ), the relative crystallinity is 101%. Its adsorption isotherm and pore distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com