Cavity ring-down spectroscopy-based tunable laser line width measurement method

A technology for cavity ring-down spectroscopy and laser tuning, which is applied in measurement devices, instruments, and optical devices, etc., can solve expensive and complex problems, and achieve the effects of high signal-to-noise ratio, convenient data processing, and high anti-interference ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

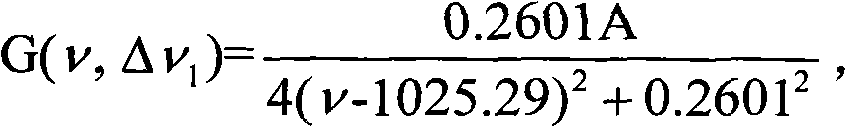

[0028] Attached below figure 1 The system describes the method for measuring linewidth of tunable lasers based on optical cavity ring-down spectroscopy of the present invention.

[0029] Light source 1 selects high beam quality (TEM 00 mode) tunable quantum cascade laser with a lasing wavelength of 1022.9cm -1 ~1028.4cm -1 , the spatial filtering and telescope system 2 consists of two lenses and a pinhole to shape the incident beam to match the optical cavity mode; two identical plano-concave high-reflection mirrors with high-reflection coating on the concave surface (reflectivity greater than 99% ) concave surface constitutes a ring-down cavity 3, the ring-down cavity is a stable cavity or a confocal cavity, and the cavity length L satisfies 0-24 cm-1 / mol cm -2 For a complete absorption line of magnitude, the chamber is filled with a dry mixture of carbon dioxide gas and nitrogen, wherein the carbon dioxide content accounts for about 4%, and the pressure in the chamber is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com