Farmland fertilization system of potato starch process water and application method thereof

A technology of potato starch and process water, which is applied in the field of farmland fertilization system, can solve the problems of unfavorable clean water saving water resources, soil compaction, occupying farmland cultivation area, etc., and achieve the benefits of soil absorbing nutrients, saving water resources and enhancing absorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

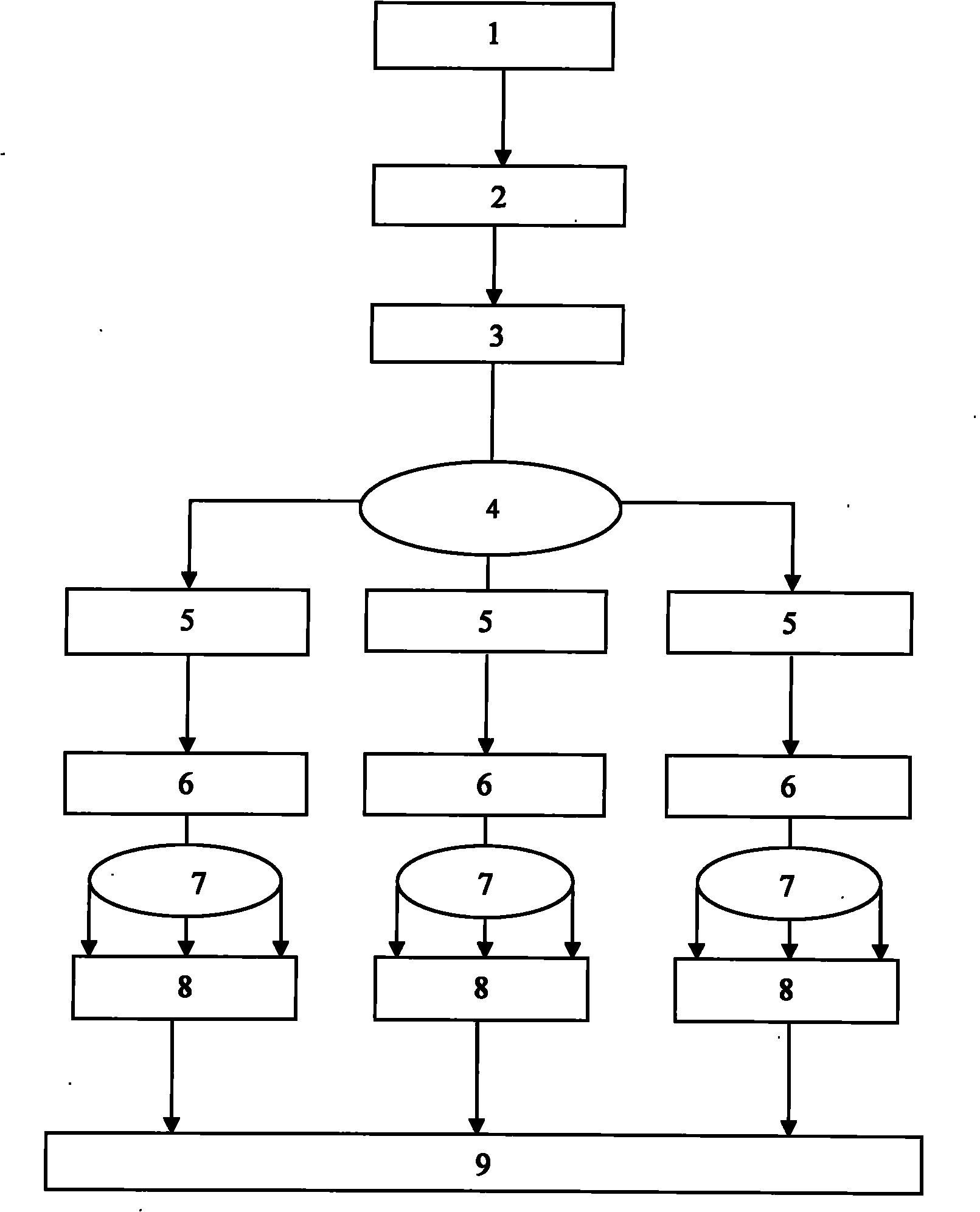

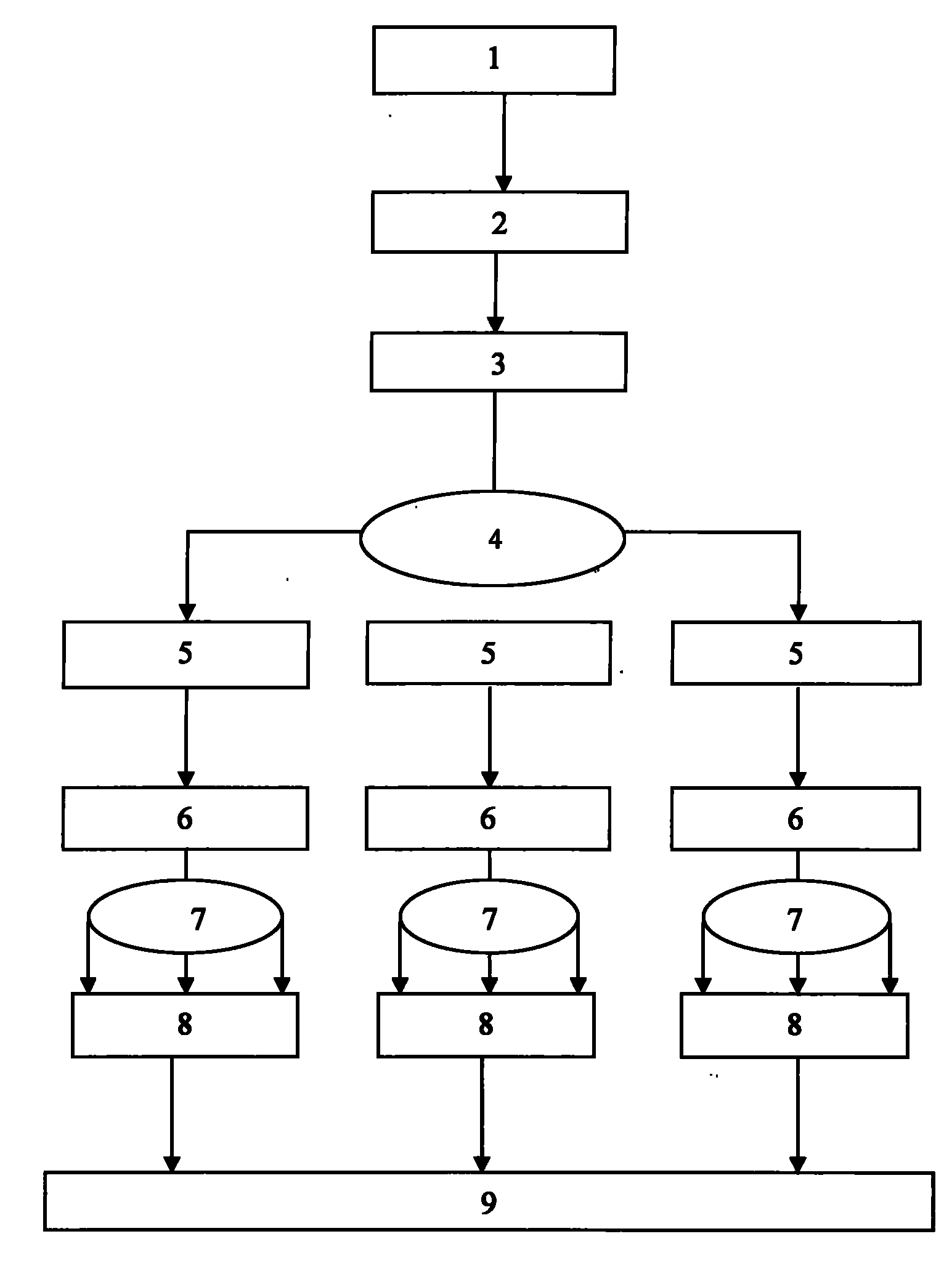

[0017] Embodiment 1: a kind of potato starch process water farmland fertilization system, it includes following devices: centrifugal screen group and cyclone group 1, anti-seepage storage tank 2, pumping station 3, underground pipe network 4, field water diversion tank 5. Pressurized pump station 6, branch pipe network 7, movable hose 8, field sprinkler 9, wherein, the centrifugal screen group and the cyclone group 1 are connected to the anti-seepage storage tank 2, and the anti-seepage storage tank 2 is connected to the lifting pump The station 3 is connected, the pumping station 3 is connected with the field water distribution tank 5 through the underground pipe network 4, the field water distribution tank 5 is connected with the pressurized pump station 6, and the pressurized pump station 6 is connected with the movable hose 8 through the branch pipe network 7, One group of said field nozzles 9 are established every 5 meters on the movable hose 8, and each group of nozzles i...

Embodiment 2

[0019] Embodiment 2: adopt the potato starch process water farmland fertilization system of embodiment 1, the technological process of carrying out potato starch process water farmland fertilization is: (1) the production water of washing starch is mixed with potato juice by centrifugal sieve group and cyclone group The process water enters the anti-seepage storage tank of the factory, wherein the potato starch process water is the mixed substance of the juice of the potato itself and the starch washing water in the starch processing process; (2) the potato starch process water is naturally carried out in the anti-seepage storage tank of the factory Biological aeration treatment, shelving time 7 days; (3) Process water after natural biological aeration treatment enters the field water distribution tank through the pumping station and underground pipe network, and the underground main network is underground in the farmland; (4) The process water is mixed with clear water from th...

Embodiment 3

[0020] Embodiment 3: adopt the potato starch process water farmland fertilization system of embodiment 1, the technological process of carrying out potato starch process water farmland fertilization is: (1) the production water of washing starch is mixed with potato juice by centrifugal sieve group and cyclone group The process water enters the anti-seepage storage tank of the factory, wherein the potato starch process water is the mixed substance of the juice of the potato itself and the starch washing water in the starch processing process; (2) the potato starch process water is naturally carried out in the anti-seepage storage tank of the factory Biological aeration treatment, shelving time 8 days; (3) The process water after natural biological aeration treatment enters the field water distribution tank through the pumping station and the underground pipe network, and the underground main network is underground in the farmland; (4) The process water is mixed with clean water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com