Pressure pulsation ultrasonic atomization culture device and cultural method using same

A technology of ultrasonic atomization and pressure pulsation, applied in horticultural methods, botanical equipment and methods, horticulture, etc., can solve problems such as inability to carry out large-scale cultivation, enlargement of reactor volume, poor dispersion of droplets, etc., and save raw materials. , High production efficiency, uniform growth state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

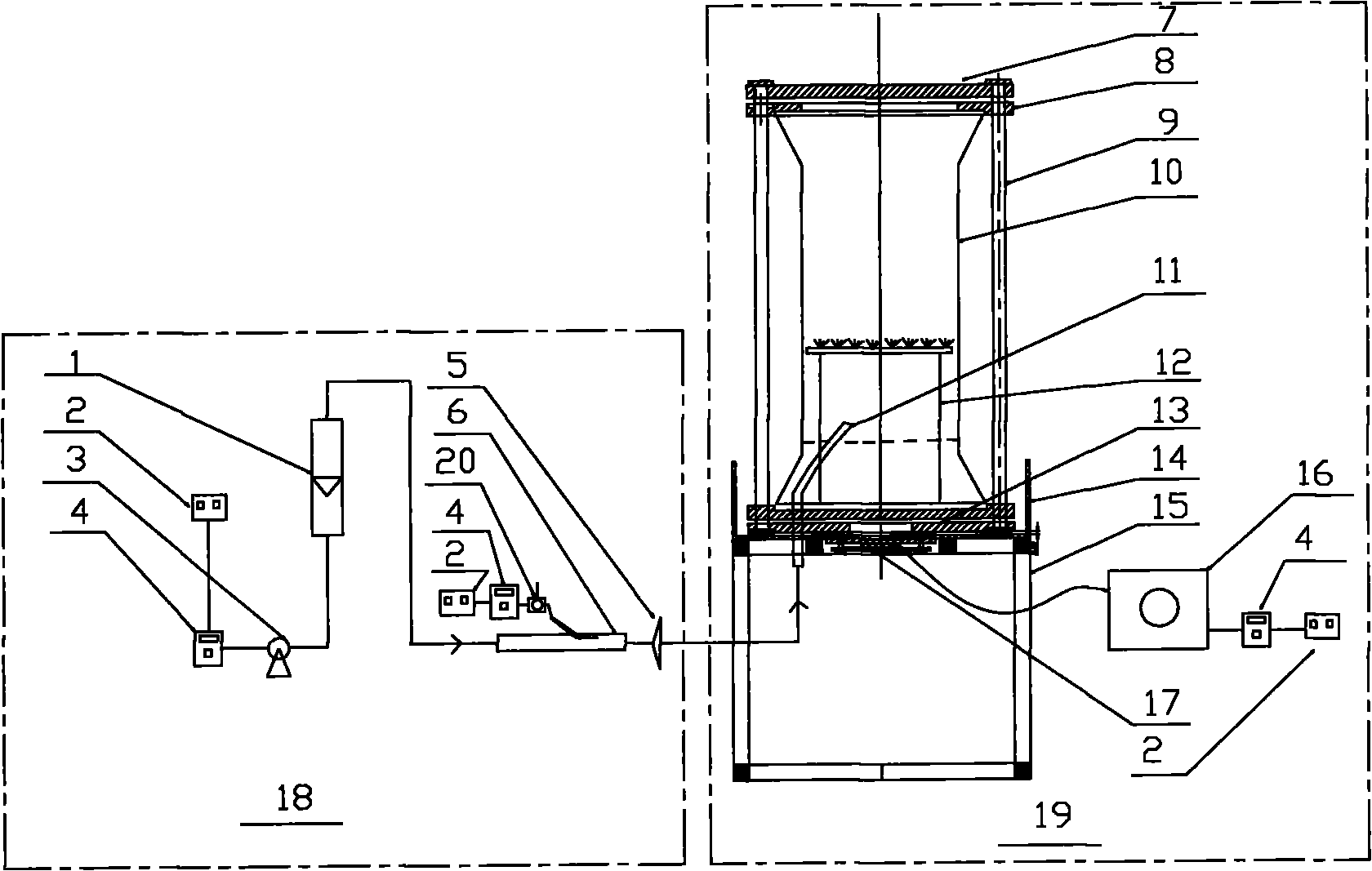

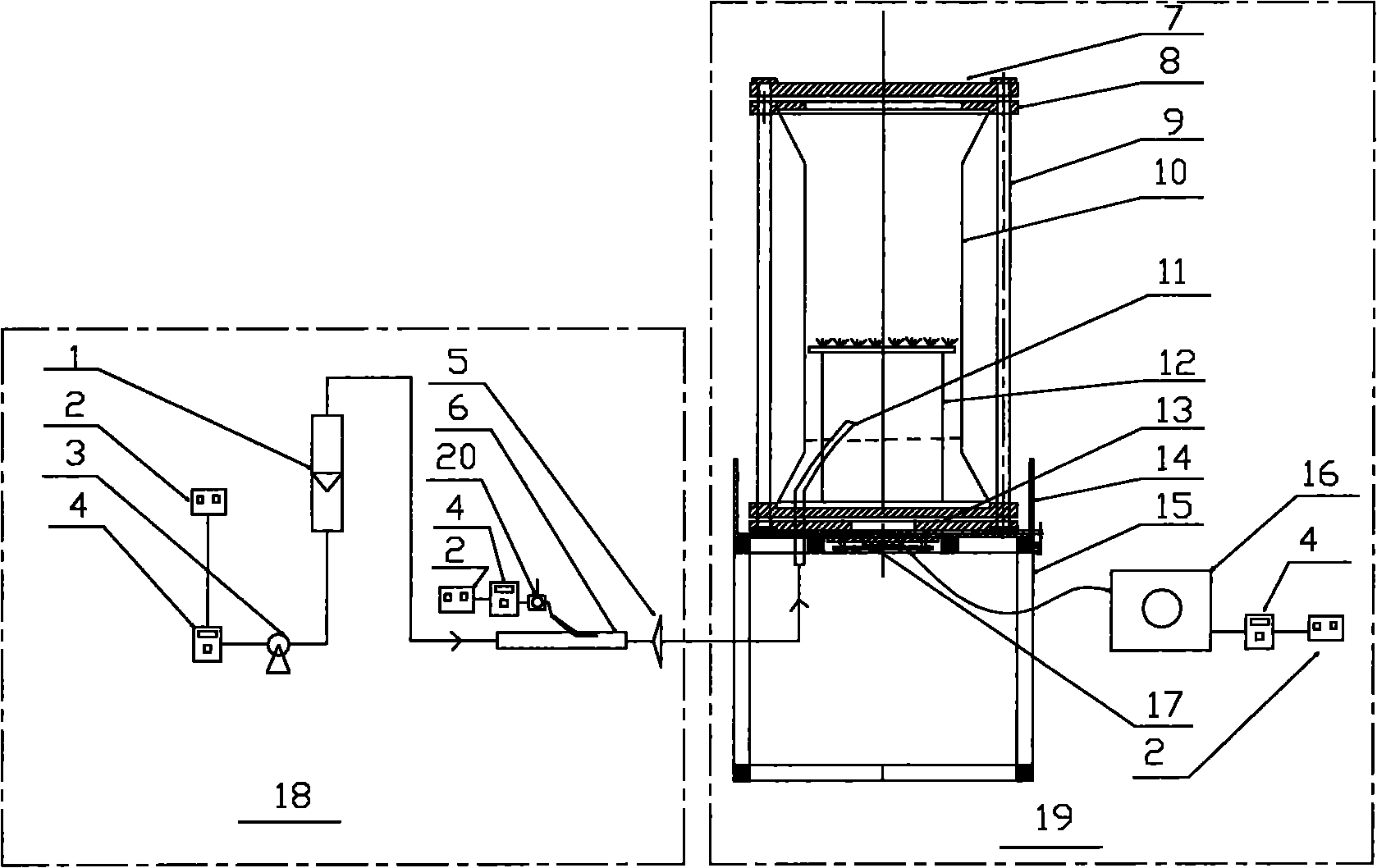

[0043] Rapid Propagation of Rhodiola longipsifolia by Using Pressure Pulse Ultrasonic Atomization Culture Device

[0044] Such as figure 1 As shown, the pressure pulsation ultrasonic atomization culture device is composed of two systems: one is the pressure control system. The system includes a time relay 4 , an air pump 3 , an air distribution tee 6 , a gas flow meter 1 , an air filter 5 and a solenoid valve 20 . Wherein the gas distribution tee 6 comprises three ports, two ports have the same size, and the diameter of the third port is 5% of the diameter of the first two ports. By adjusting the opening of the gas flow meter 1, the air flow rate entering the reactor is adjusted so that the pressure in the reactor reaches 1.2 atm. During operation, the air pump is controlled by a time relay. At the same time, the solenoid valve is closed under the control of the time relay, so that the air injected by the air pump can only flow through the larger end of the air distribution...

Embodiment 2

[0053] Rapid Propagation of Rhodiola grandiflora by Pressure Pulse Ultrasonic Atomization Culture Device

[0054] The specific implementation steps of the technique of carrying out the large-scale propagation of Rhodiola grandiflora using the same device as described in Example 1 are:

[0055] 1. Same as step 1 in Example 1.

[0056] 2. The seeds germinate on the culture medium and grow roots, stems, and leaves. Take the leaves and cut them into small sections of 0.5 cm with a scalpel. Prepare MS medium, add agar powder 5%, sucrose 30%, 2.5 mg / L BAP and 0.2 mg / L GA 3 , sterilized at 121°C for 17 minutes. The cut plant material is inoculated on the culture medium, and then placed in a culture room at 25±2°C, with a light intensity of 4000Lux and a photoperiod of 16 hours.

[0057] 3. After the plant material dedifferentiates and grows clustered buds, take out the clustered buds as the initial material for reactor culture. Prepare MS medium with 30% sucrose, 2.5 mg / L BAP and...

Embodiment 3

[0061] Rapid Propagation of Xinjiang Snow Lotus by Using Pressure Pulse Ultrasonic Atomization Cultivation Device

[0062] Except that the diameter of the third port of the gas distribution tee is 1% of the diameter of the first two ports, and the pressure in the reactor is controlled at 1.5 atm, all the other devices are the same as those described in Example 1. The specific implementation steps of the technique of adopting the above device to carry out the large-scale propagation of Xinjiang Snow Lotus are:

[0063] 1. Same as step 1 in Example 1.

[0064] 2. The seeds germinate on the medium and grow roots, stems, and leaves. Take the leaves and cut them into 0.5cm with a scalpel 2 small pieces. MS medium was prepared by adding 5% agar powder, 30% sucrose, 2.5 mg / L BAP and 0.5 mg / L NAA, and sterilized at 121° C. for 17 minutes. The cut plant material is inoculated on the culture medium, and then placed in a culture room at 25±2°C, with a light intensity of 4000Lux and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com