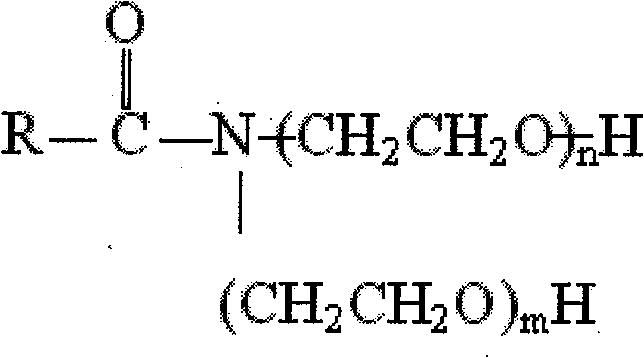

Preparation method of alkanolamide polyoxyethylene ether and application thereof

A technology of polyoxyethylene ether and alkanolamide, which is applied in the preparation of carboxylic acid amide, preparation of organic compounds, chemical instruments and methods, etc., can solve the problem of increasing the difficulty and additional cost of oil recovery, affecting the normal production of oil wells, and corrosion of equipment and pipelines and other problems, to achieve the effect of excellent salt resistance, excellent interfacial tension and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

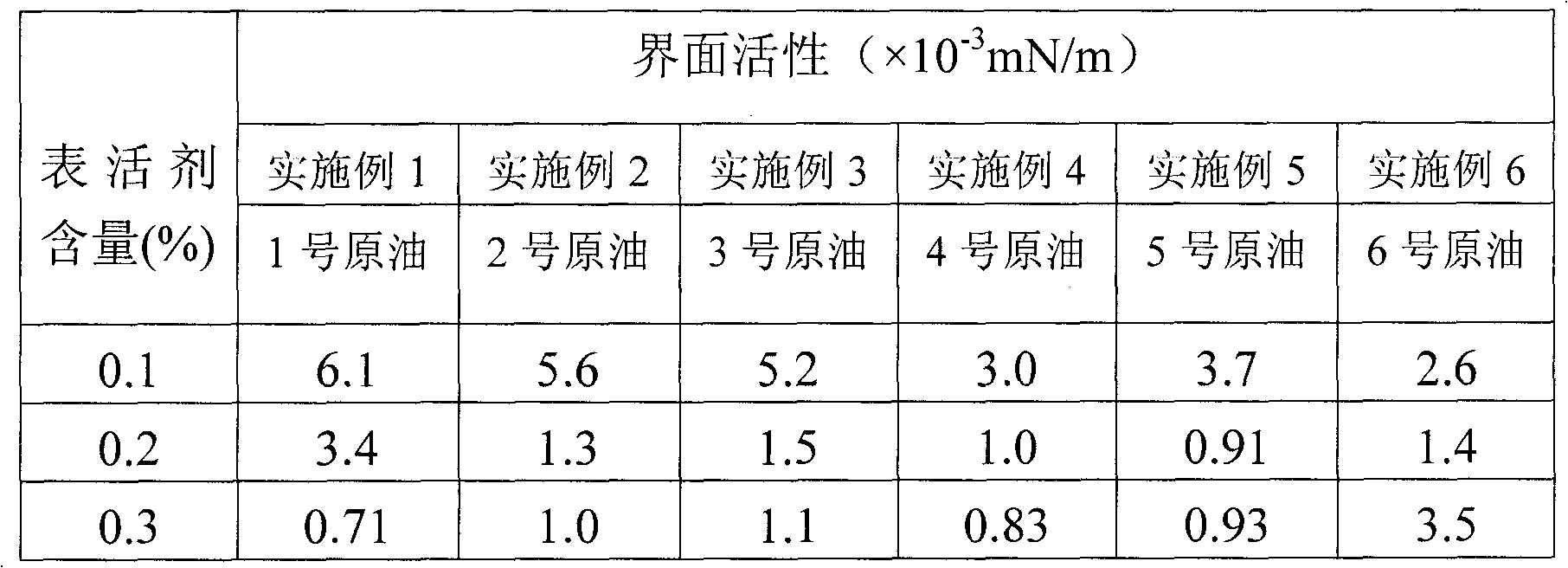

Examples

Embodiment 1

[0018] Put 368 kg of stearic acid into the pressure reactor, stir and heat up until the fatty acid is completely melted, then add 61 kg of monoethanolamine into the reactor, and then add 2.5 kg of KOH catalyst. Nitrogen gas was introduced, vacuum was pumped, and this was repeated three times. The pressure in the reactor was controlled at 0.02M Pa, the temperature was controlled at 120-170°C, and the reaction was carried out for 6 hours. Then pass in nitrogen to control the temperature at 160°C, then pass in 220 kg of ethylene oxide at an absolute pressure of 0.3 to 0.4 MPa; keep warm at 180°C for 60 minutes; pass in nitrogen, cool down to 75°C, and the discharge will be added product.

Embodiment 2

[0020] Put 368 kg of stearic acid into the pressure reactor, stir and heat up until the fatty acid is completely melted, then add 95 kg of diethanolamine into the reactor, and then add 5 kg of KOH catalyst. Nitrogen gas was introduced, vacuum was pumped, and this was repeated three times. The pressure in the reactor was controlled at 0.02M Pa, the temperature was controlled at 120-170°C, and the reaction was carried out for 12 hours. Then feed nitrogen to control the temperature at 160°C, and at an absolute pressure of 0.3 to 0.4 MPa; feed 440 kg of ethylene oxide; at 180°C, keep warm for 60 minutes; feed nitrogen, cool down to 75°C, and discharge; into products.

Embodiment 3

[0022] Put 340 kg of palmitic acid into the pressure reactor, stir and heat up until the fatty acid is completely melted, then add 95 kg of diethanolamine into the reactor, and then add 3.5 kg of KOH catalyst. Nitrogen gas was introduced, vacuum was pumped, and this was repeated three times. The pressure in the reactor was controlled at 0.02M Pa, the temperature was controlled at 120-170°C, and the reaction was carried out for 8 hours. Then feed nitrogen to control the temperature at 160°C, at an absolute pressure of 0.3-0.4MPa; feed 410 kg of ethylene oxide; at 180°C, keep warm for 60 minutes; feed nitrogen, cool down to 75°C, and discharge; into products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com