Method for realizing slowly-varying lamination antireflection coating of solar cell

A solar cell, anti-reflection technology, applied in coatings, circuits, electrical components, etc., can solve the problems of long time and difficult control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will now be described in further detail.

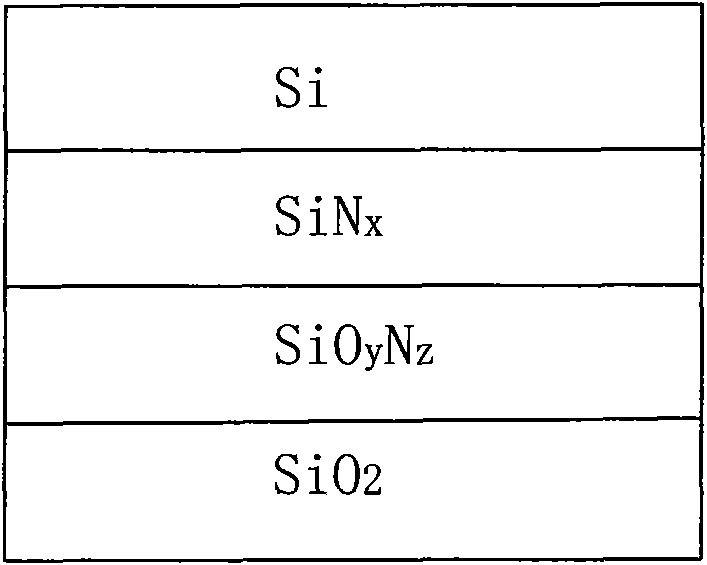

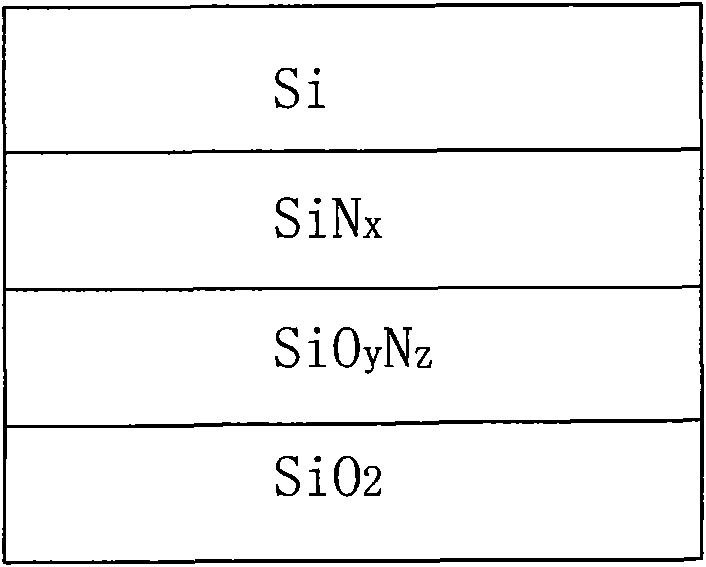

[0015] The method for realizing the solar cell slow-change stacked anti-reflection film is to deposit the anti-reflection film on the light-receiving surface of the solar cell silicon wafer after treatment through the chemical vapor deposition process, and the gas at the beginning of the deposition is SiH 4 and NH 3 mixed gas or SiH 4 and N 2 mixed gas, N was gradually added during the deposition process 2 O, so that the composition of the film changes from silicon nitride on the surface of the silicon wafer to silicon oxynitride on the outer layer and then to silicon dioxide on the outer layer.

[0016] The chemical vapor deposition process is to deposit on the front side of the silicon wafer at a temperature of 200°-400°. The silicon wafer is P-type or N-type single crystal silicon, and the resistivity of the silicon wafer is 0.2Ωcm-10Ωcm. The gas at the beginning of the chemical vapor deposition pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com