Preparation method of nanogold-fullerene nano composite material

A nano-composite material and nano-gold technology, which is applied in the field of preparation of nano-gold-fullerene nano-composite materials, can solve complex and other problems, achieve the effect of convenient synthesis steps, simple synthesis process, avoiding chemical reactions and purification processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

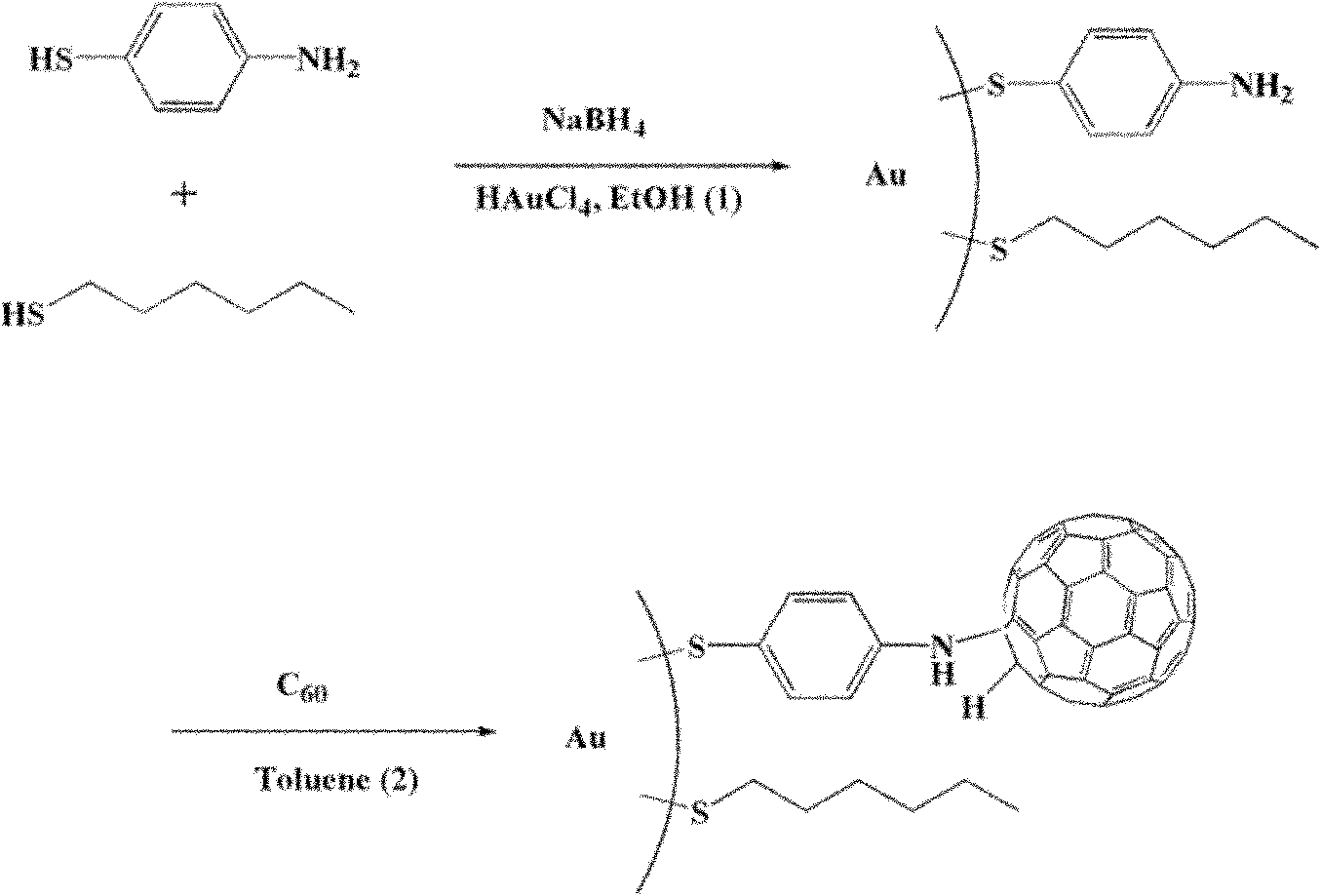

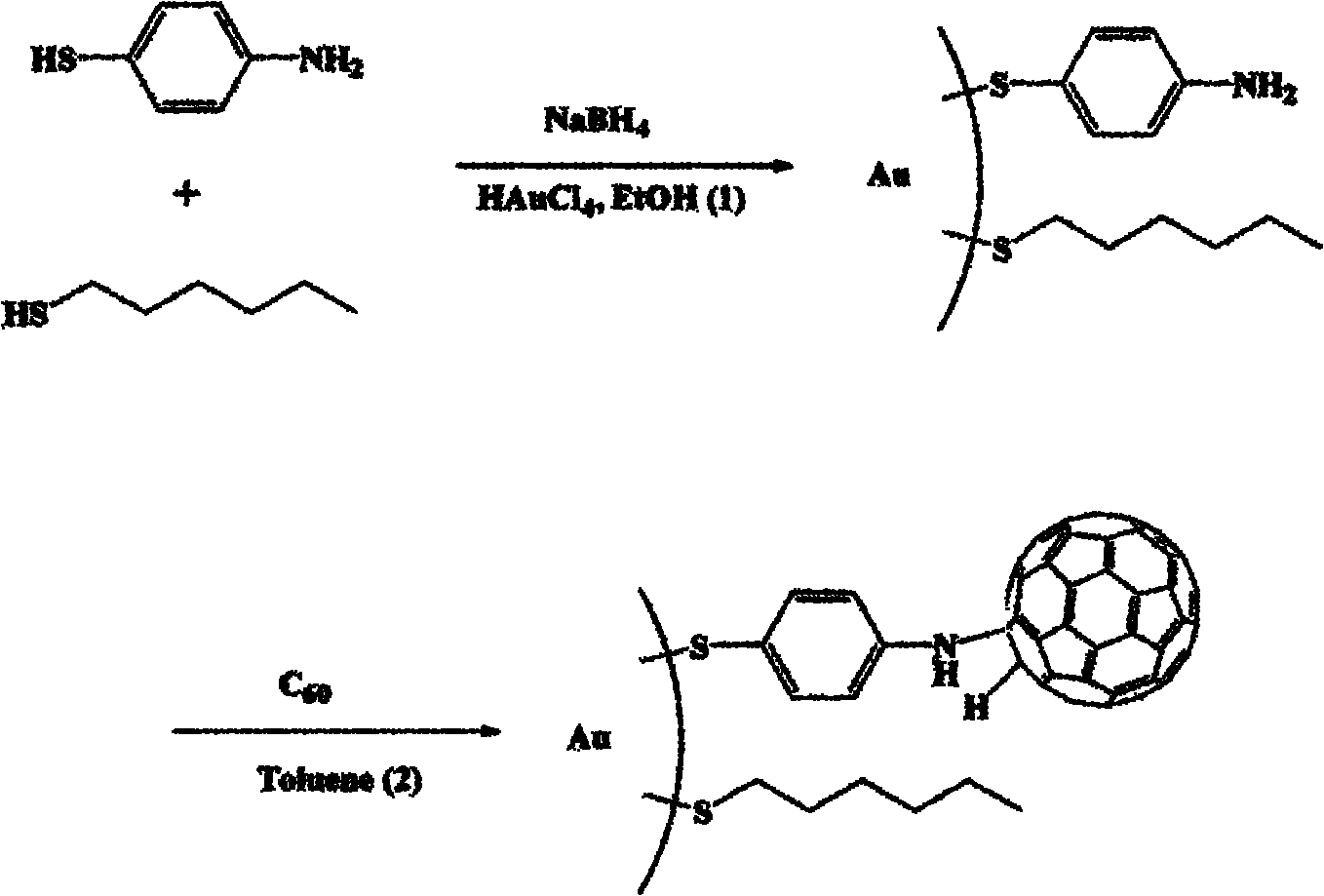

[0032] Embodiment 1 prepares the gold nanometer of 4-aminobenzenethiol / n-hexanethiol protection

[0033] The thiol compounds 4-Aminobenzenethiol (4-Aminobenzenethiol) and n-hexanethiol (1-Hexanethiol) (purity>96.0%) used in the experiment were purchased from TCI, Japan.

[0034] (1) 0.9 mmol of chloroauric acid hydrate (AuCl 3 ·HCl·4H 2 O) be dissolved in the dehydrated alcohol of 200 milliliters, after the system is vigorously stirred for 10 minutes, add 0.9 mmol of 4-aminobenzenethiol / n-hexanethiol (the molar ratio of 4-aminobenzenethiol and n-hexanethiol is 1: 1).

[0035] (2) 30 mL of freshly prepared NaBH 4 Ethanol solution (0.40mol / L) was slowly added to the mixed solution, and the dropwise addition time was two to two hours. Once the GNPs are formed, the color of the system changes from yellow to dark brown.

[0036] (3) The dark brown solution was continuously stirred for 3 hours, and then the mixture was stored in a refrigerator at -18° C. for 6-12 hours to contr...

Embodiment 2

[0040] Embodiment 2 prepares nano-gold-fullerene nanocomposite material

[0041] (1) 20 micromoles of fullerene and 5 micromoles of dry gold nanoparticles were respectively dispersed in 50 milliliters of toluene (or carbon tetrachloride) and ultrasonicated for 10-20 minutes before the next step of reaction, and then the two solutions Mix and stir vigorously at room temperature for 60-84 hours.

[0042] Wherein, the molar ratio of fullerene to gold nanoparticles is greater than 1.

[0043] (2) The solution containing the fullerene-metal composite is concentrated to 20 ml in a rotary evaporator at 50-60°C.

[0044] (3) Methanol or acetone (three times the volume of toluene) was added to the toluene solution, and then the mixture was purified by centrifugation (10000 rpm, 10 min).

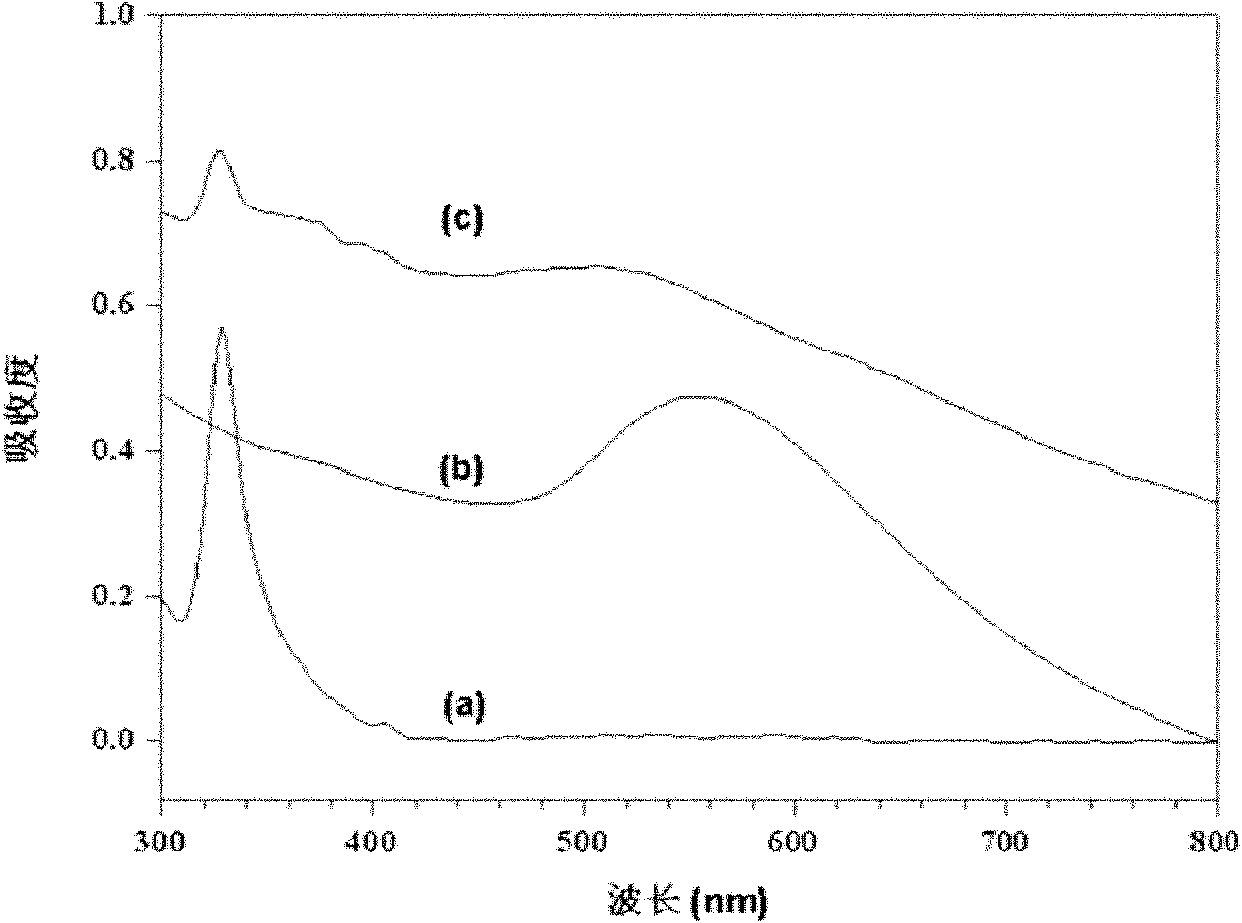

[0045] Among them, the solubility of the fullerene-metal composite material in methanol or acetone is lower than that of fullerene, and the purpose of separating the two is achieved by centrifugatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com