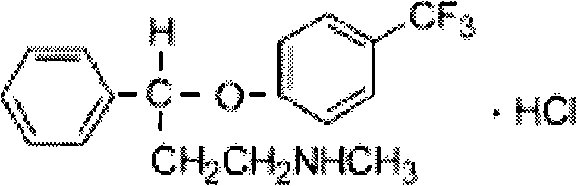

Method for preparing antidepressant fluoxetine

A technology for medicine fluoxetine and antidepressant, applied in the field of preparation of pharmaceutical compounds, can solve problems such as environmental pollution of fluoxetine, achieve the effects of improving reaction conversion rate, facilitating reaction speed and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

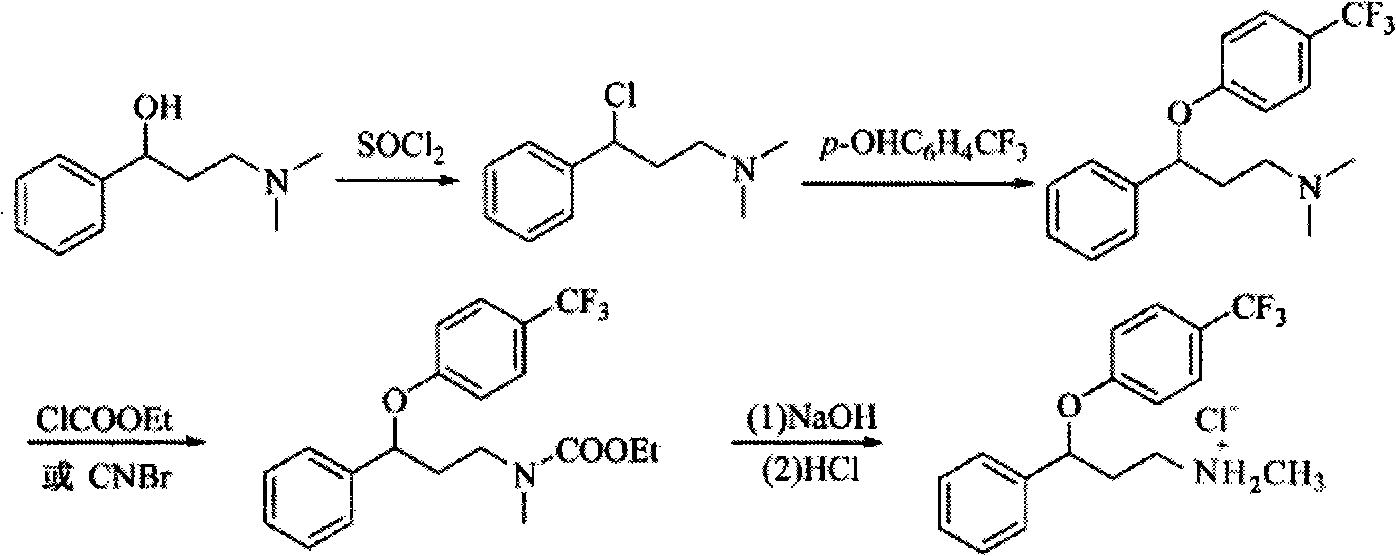

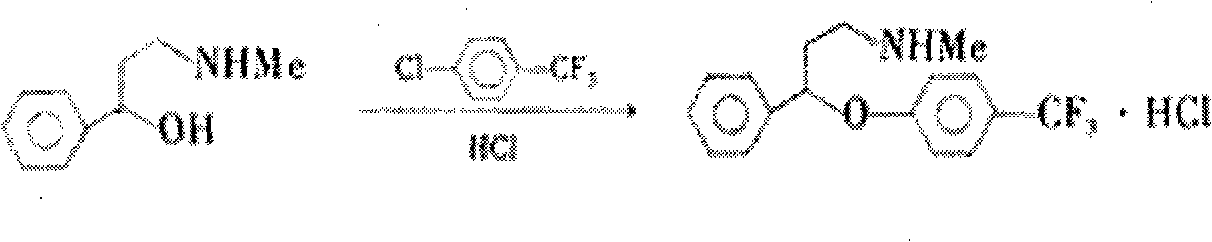

Method used

Image

Examples

Embodiment 1

[0044] 1.68g (0.01mol) of β-chloropropiophenone was put into the high-pressure reactor lined with polytetrafluoroethylene, and 10ml of deoxidized i-C 3 h 7 OH solvent, seal the reactor, replace the air in the reactor with nitrogen for 3 times, replace the nitrogen with methylamine gas for 3 times, adjust the pressure of the reactor to 0.1MPa, turn on the stirrer, slowly raise the temperature to 80°C, and after 12 hours of reaction, drop to to room temperature, replace the gas in the reaction system with nitrogen for 3 times, open the reaction kettle, and put Ru / γ-Al 2 o 3 Support the catalyst (the preparation of the catalyst has been described in the 200910095808.1 patent specification), add 0.056g (0.001mol) of KOH, and seal the autoclave.

[0045] Use high-purity nitrogen to replace the air in the high-pressure reactor for 3 times, and then use hydrogen to replace the nitrogen for 3 times, then fill the hydrogen to 1MPa, the reaction temperature is 100°C, and react for 10 ...

Embodiment 2

[0049] 2.52g (0.015mol) β-chloropropiophenone is put into the high-pressure reactor of lining polytetrafluoroethylene, adds the tetrahydrofuran solvent of 20ml, seals the reactor, replaces the air in the reactor with nitrogen for 5 times, passes through methanol Replace the nitrogen with amine for 5 times, adjust the pressure of the reactor to 0.5MPa, turn on the stirrer, slowly raise the temperature to 100°C, react for 10 hours, then cool down to room temperature, replace the gas in the reaction system with nitrogen for 5 times, and put Ru-Pd / γ-Al 2 o3 Support the catalyst (the preparation of the catalyst has been described in the 200910095808.1 patent), add 0.040 g (0.001 mol) of NaOH, and seal the autoclave.

[0050] Use high-purity nitrogen to replace the air in the high-pressure reactor for 5 times, and then use hydrogen to replace the nitrogen for 5 times, then fill the hydrogen to 1.2MPa, the reaction temperature is 120°C, and react for 6 hours. During the reaction, the ...

Embodiment 3

[0053] 3.36g (0.02mol) β-chloropropiophenone is put into the high-pressure reactor lined with polytetrafluoroethylene, add 20ml of dimethylformamide solvent, seal the reactor, and replace the air in the reactor with nitrogen for 5 times , feed methylamine to replace nitrogen 5 times, adjust the pressure of the reactor to 0.4MPa, turn on the stirrer, slowly raise the temperature to 60°C, after 11 hours of reaction, lower the reaction temperature to room temperature, replace the gas in the reaction system with nitrogen 5 times, put in Rh / γ-Al 2 o 3 Loaded catalyst (the preparation of the catalyst has been described in the 200910095808.1 patent), add 0.106g (0.001mol) of Na 2 CO 3 , Sealed autoclave.

[0054] Use high-purity nitrogen to replace the air in the high-pressure reactor for 5 times, and then use hydrogen to replace the nitrogen for 5 times, then fill the hydrogen to 1.5MPa, the reaction temperature is 60°C, and react for 8 hours. During the reaction, the hydrogen p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com