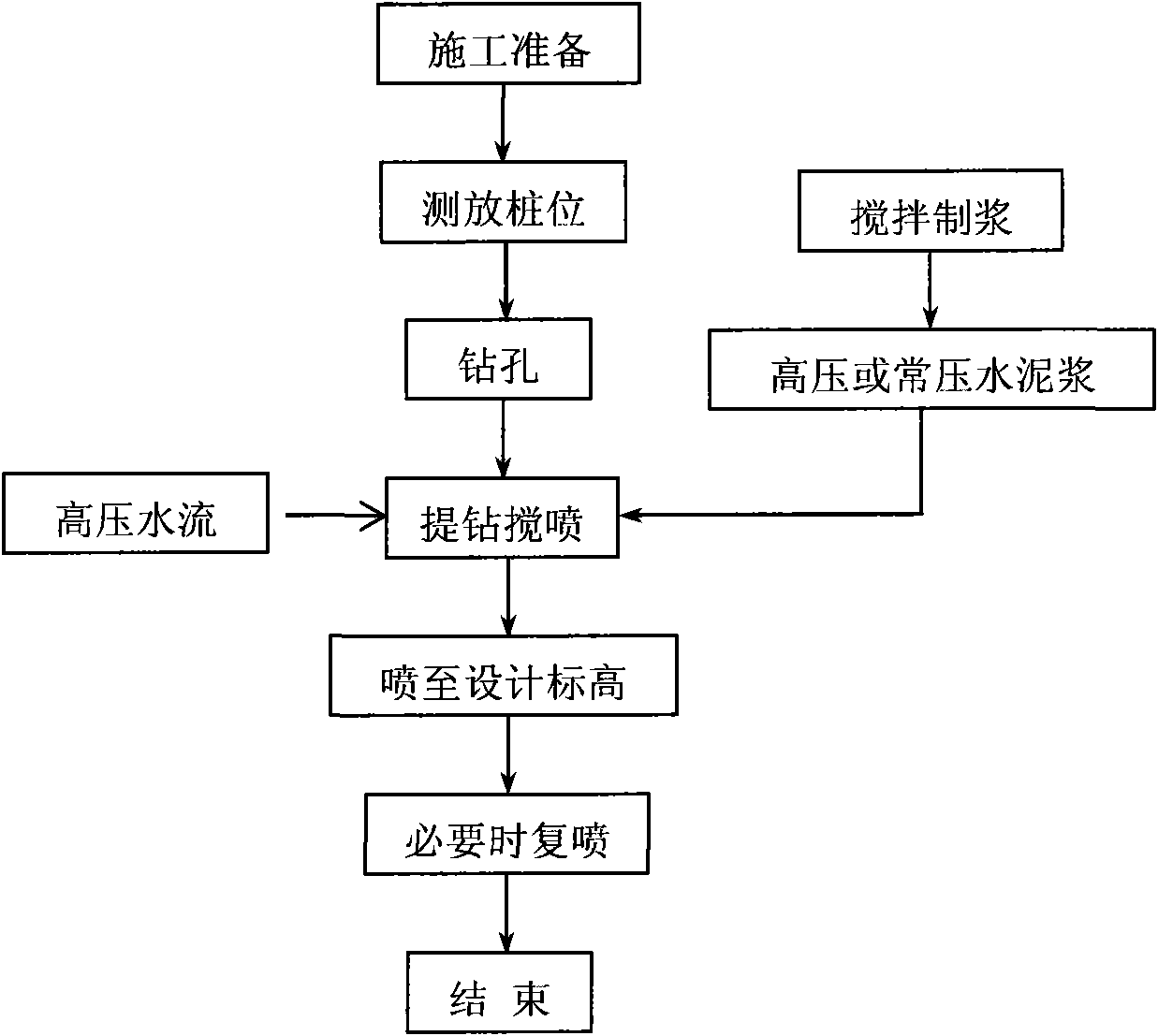

Long spiral double-pipe high-pressure stir-jet grouting pile construction method and device

A construction method and construction device technology, applied to drilling equipment and methods, drill pipes, casings, etc., can solve problems such as high construction cost, low construction efficiency, and excessive lifting speed, so as to reduce construction cost and simplify construction process, the effect of mitigating leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

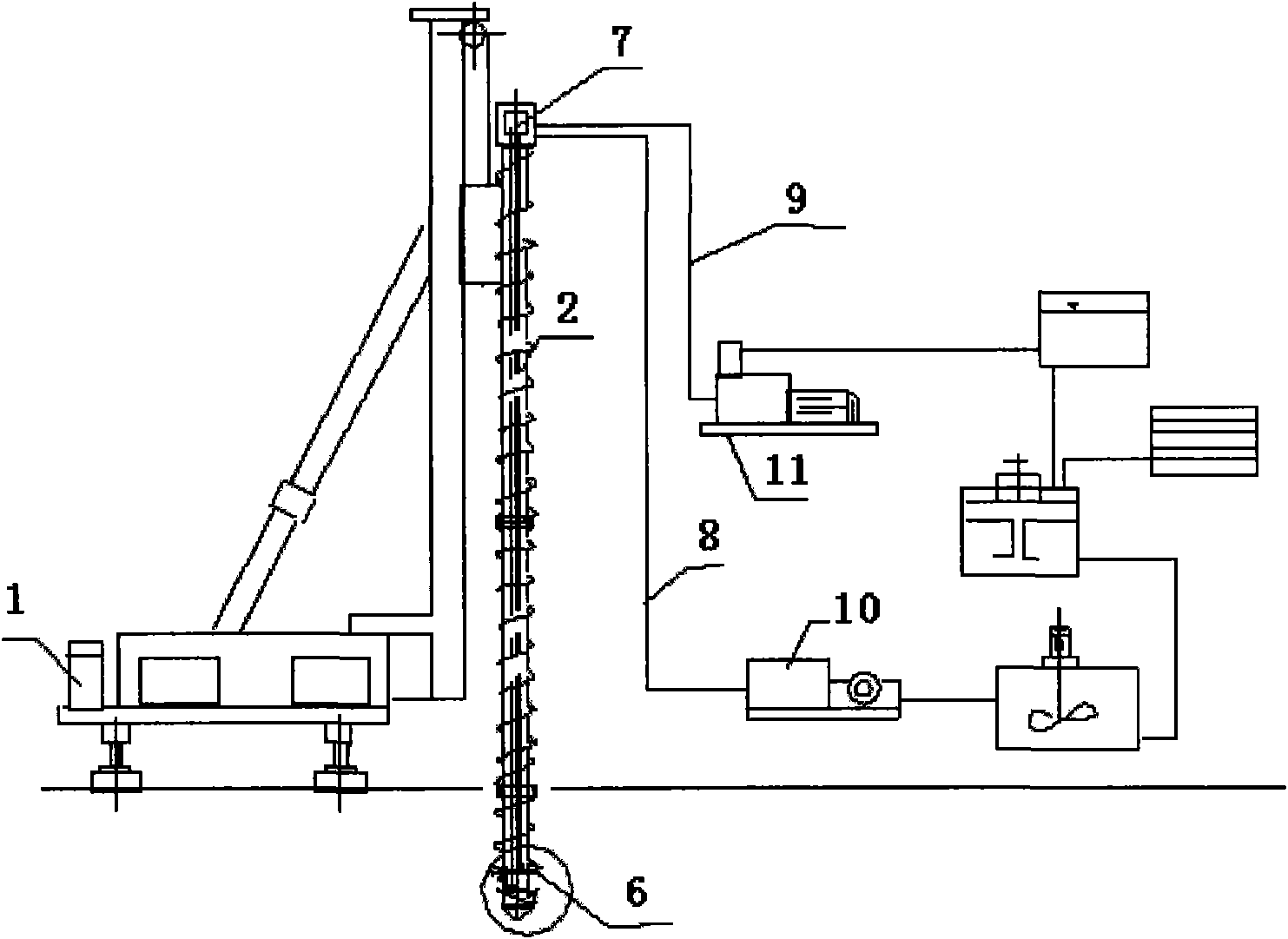

[0038] As shown in the figure, the construction equipment for the long-helix double-pipe high-pressure spraying pile is composed of three parts: the refitted long-helical drilling rig, the slurry mixing system, and the double-tube high-pressure spraying system.

[0039] Among them, the modified long helical drilling rig is equipped with variable speed control system control (1), so that the drilling rig can effectively switch between the two processes of hole forming and rotary spraying, that is, the drilling speed of the drilling rig can be increased between 3.0m / min and 1.2m / min. Fast switching between ~1.5m / min or 0.2m / min.

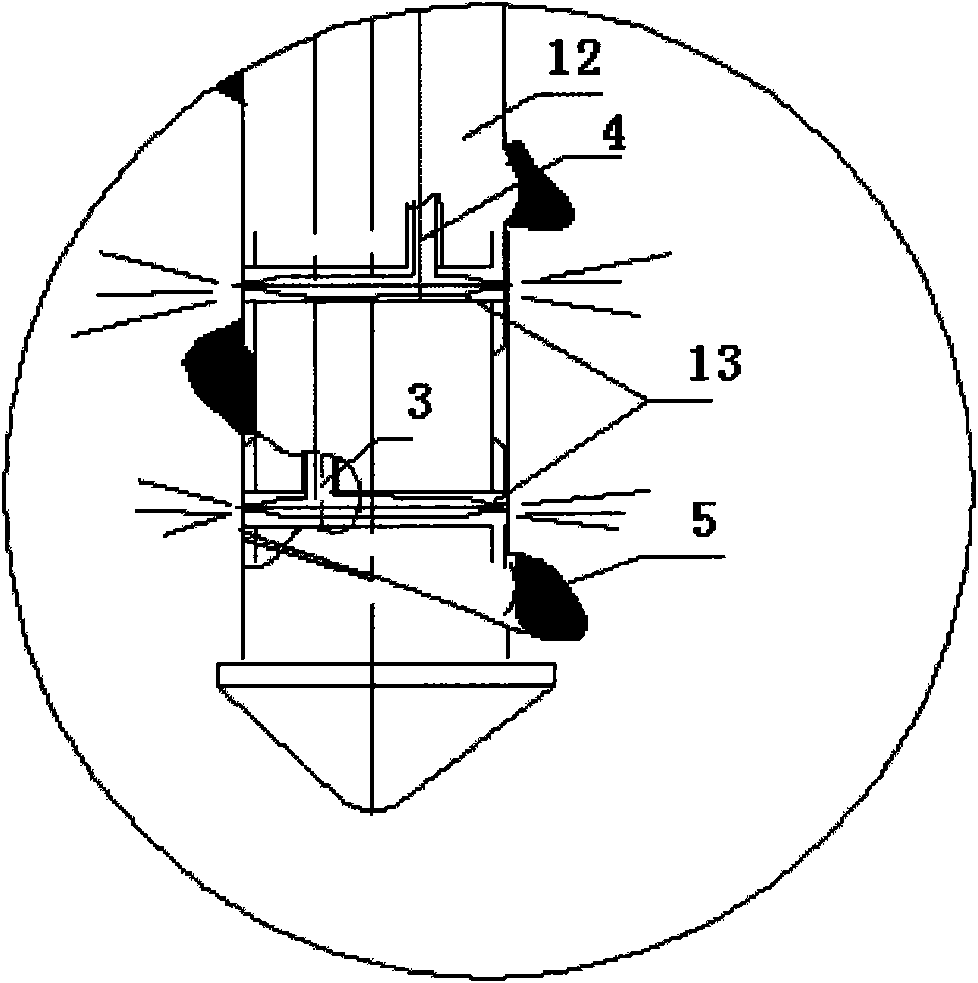

[0040] The double pipe high-pressure spray mixing system includes a hollow drill pipe (2), a high-pressure slurry pipe (3), a high-pressure wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com