Method for realizing graded laminated passivation film on back surface of solar cell

A technology of solar cells and passivation films, applied in coatings, circuits, photovoltaic power generation, etc., can solve problems such as side effects of SiNx, drop in output current and voltage, and reduced life of polycrystals, achieve superior back passivation, reduce compliance rate, the effect of reducing film stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will now be described in further detail.

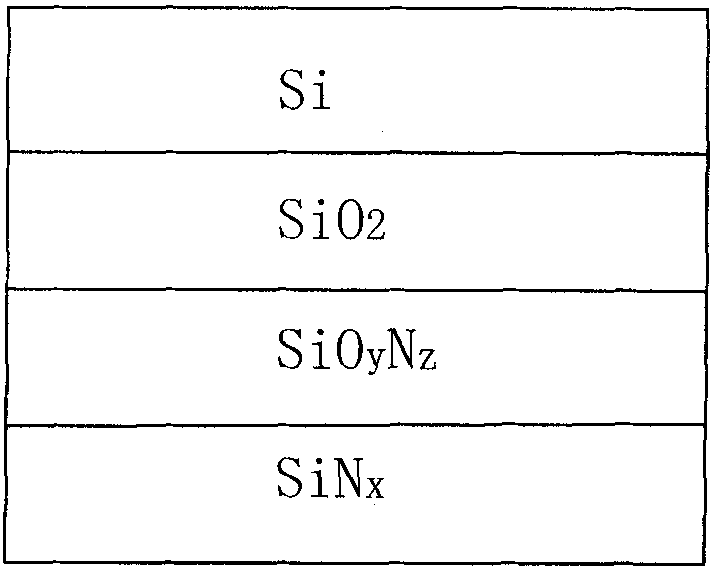

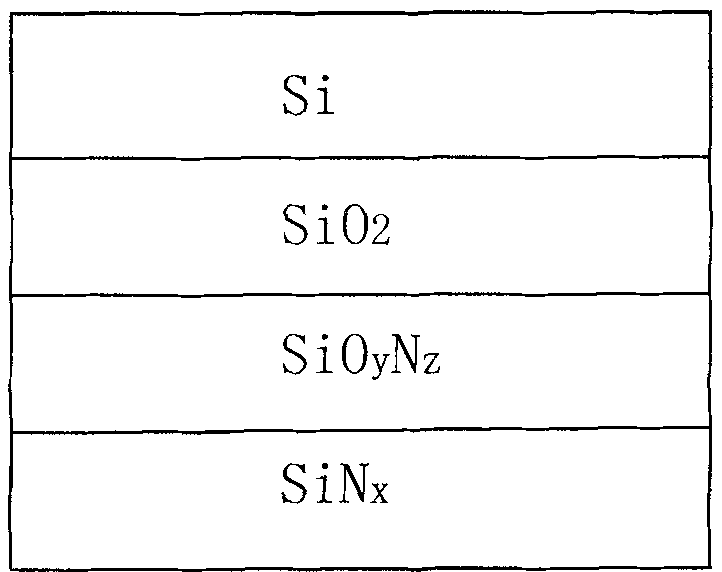

[0015] The method for realizing the slowly-varying laminated passivation film on the back surface of the solar cell is to deposit the film on the backlight surface of the silicon wafer of the solar cell after treatment by a chemical vapor deposition process, and the gas at the beginning of the deposition process is SiH 4 and N 2 A mixed gas of O, gradually adding NH during the deposition process 3 , so that the composition of the film changes from silicon dioxide on the surface of the silicon wafer to silicon oxynitride on the outer layer and then to silicon nitride on the outer layer.

[0016] The chemical vapor deposition process is to deposit on the back of the silicon wafer at a temperature of 200°-400°. The silicon wafer is P-type or N-type single crystal silicon, and the resistivity of the silicon wafer is 0.2Ωcm-10Ωcm. The gas at the beginning of the chemical vapor deposition process is SiH 4 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com