Photosensitive polyorganosiloxane composition

A technology of polyorganosiloxane and photosensitivity, which is applied in the direction of photomechanical equipment, photosensitive material processing, and photosensitive materials used in photomechanical equipment. Excellent fabricability, low viscosity, and low thermal weight loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0214] The present invention will be specifically described by the following synthesis examples, examples, and comparative examples.

Synthetic example 1

[0216] (Synthesis of polyorganosiloxane POS-1)

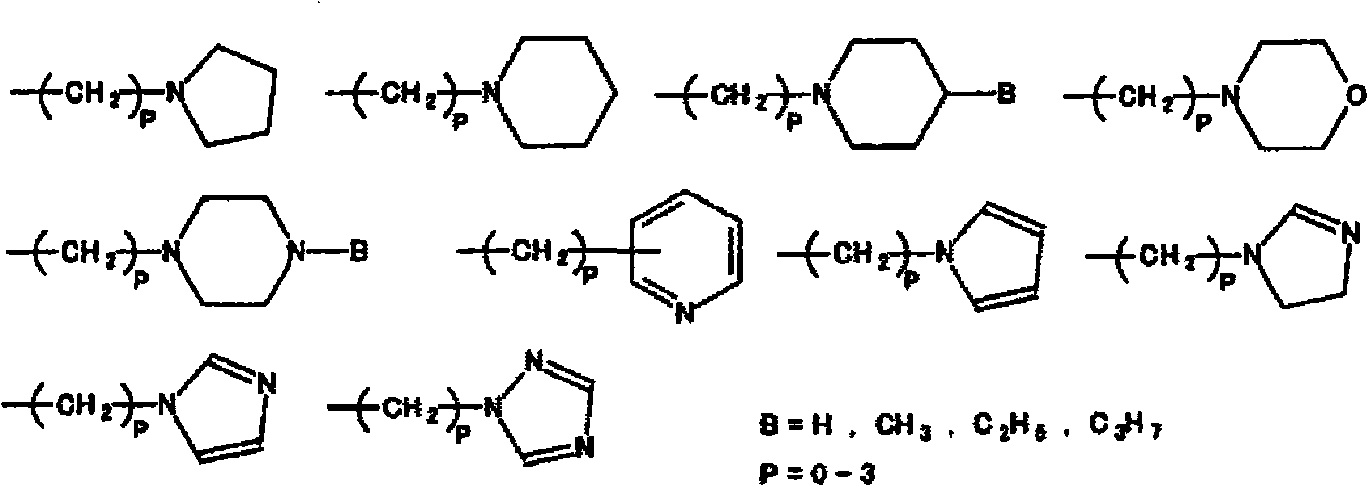

[0217] In a three-necked round-bottomed flask with a capacity of 500ml equipped with a water-cooled condenser and a vacuum-sealed stirring blade, 86.52g (0.4mol) of diphenylsilanediol (hereinafter DPD), 3-methacryloyloxypropane Trimethoxysilane (hereinafter MEMO) 52.45g (0.211mol), 3-morpholinopropyltrimethoxysilane (hereinafter MOPS) 35.12g (0.141mol), titanium tetraisopropoxide (hereinafter TIP) 6.82g (0.024mol), start stirring. (MEMO:MOPS=60:40 mol% mixing ratio) was immersed in an oil bath, the temperature was set to 120° C., and heating was started from room temperature. During this process, while the water-cooled condenser was used to reflux the methanol generated along with the progress of the polymerization reaction, it was reacted until the temperature of the reaction solution was constant, and then heating and stirring were continued for 30 minutes.

[0218] Then, a hose connecting the cold tank and a vacuum pump was...

Synthetic example 2

[0220] (Synthesis of polyorganosiloxane POS-2)

[0221] Except that the MOPS in Synthesis Example 1 was changed to 2-(2-trimethoxysilylethyl)pyridine (hereinafter PES) 32.05g (0.141mol), the same operation as Synthesis Example 1 was performed to obtain polyorganosiloxane Alkane POS-2 (viscosity 191 poise at 40°C).

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com