Preparation method of monolayer graphene

A technology of single-layer graphene and graphene, applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of human body and environmental harm, severe toxicity, etc., and achieve good stability, good biocompatibility, effective Conducive to the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] Graphene oxide is prepared by processes known to those skilled in the art. According to a preferred embodiment of the present invention, the graphene oxide solid is prepared by referring to N.I.Kovtyukhova, P.J.Ollivier, B.R.Martin, Chemistry of materials 1999, 11,771. The specific process includes: adding natural graphite powder to concentrated sulfuric acid containing potassium persulfate and phosphorus pentoxide for pre-oxidation; dispersing the pre-oxidized product in cold concentrated sulfuric acid, adding potassium permanganate and a certain amount of hydrogen peroxide The solution is processed to obtain a graphene oxide solid.

[0026] In a preferred embodiment of the present invention, the preparation steps of the graphene oxide solid include:

[0027] 30 grams of natural graphite powder were added into the concentrated sulfuric acid (45 milliliters) containing potassium persulfate (15 grams) and phosphorus pentoxide (15 grams), and reacted at 80° C. for 6 hour...

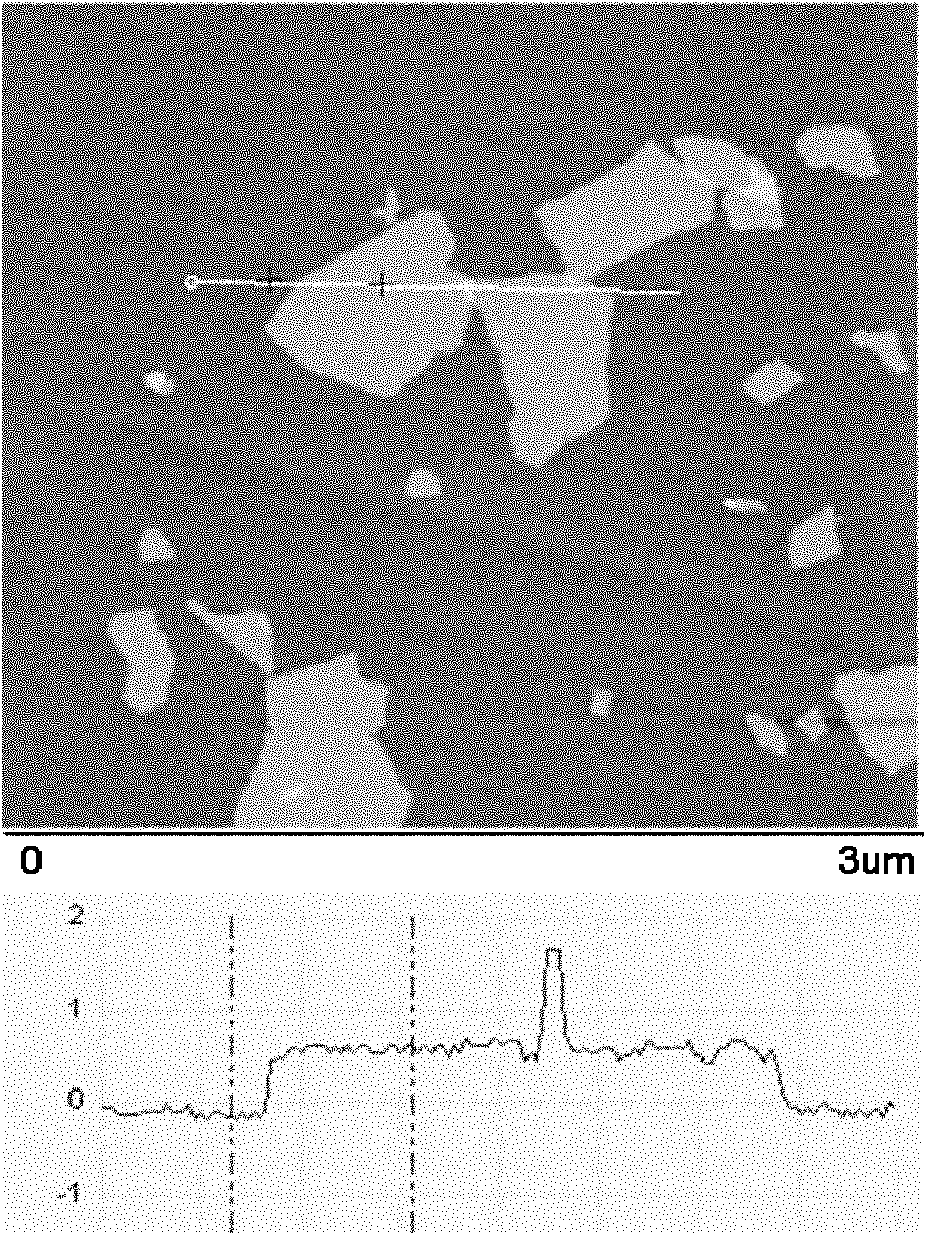

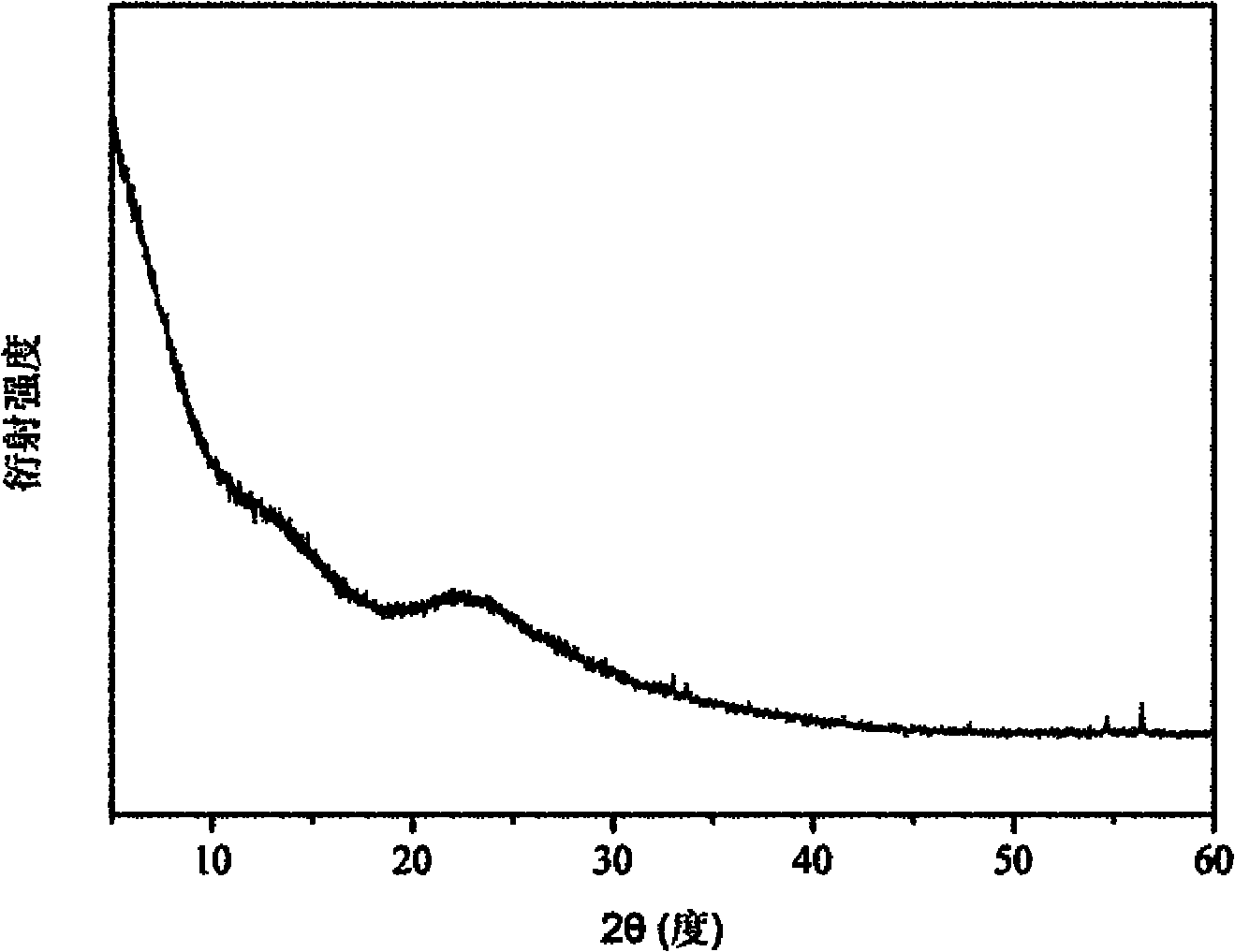

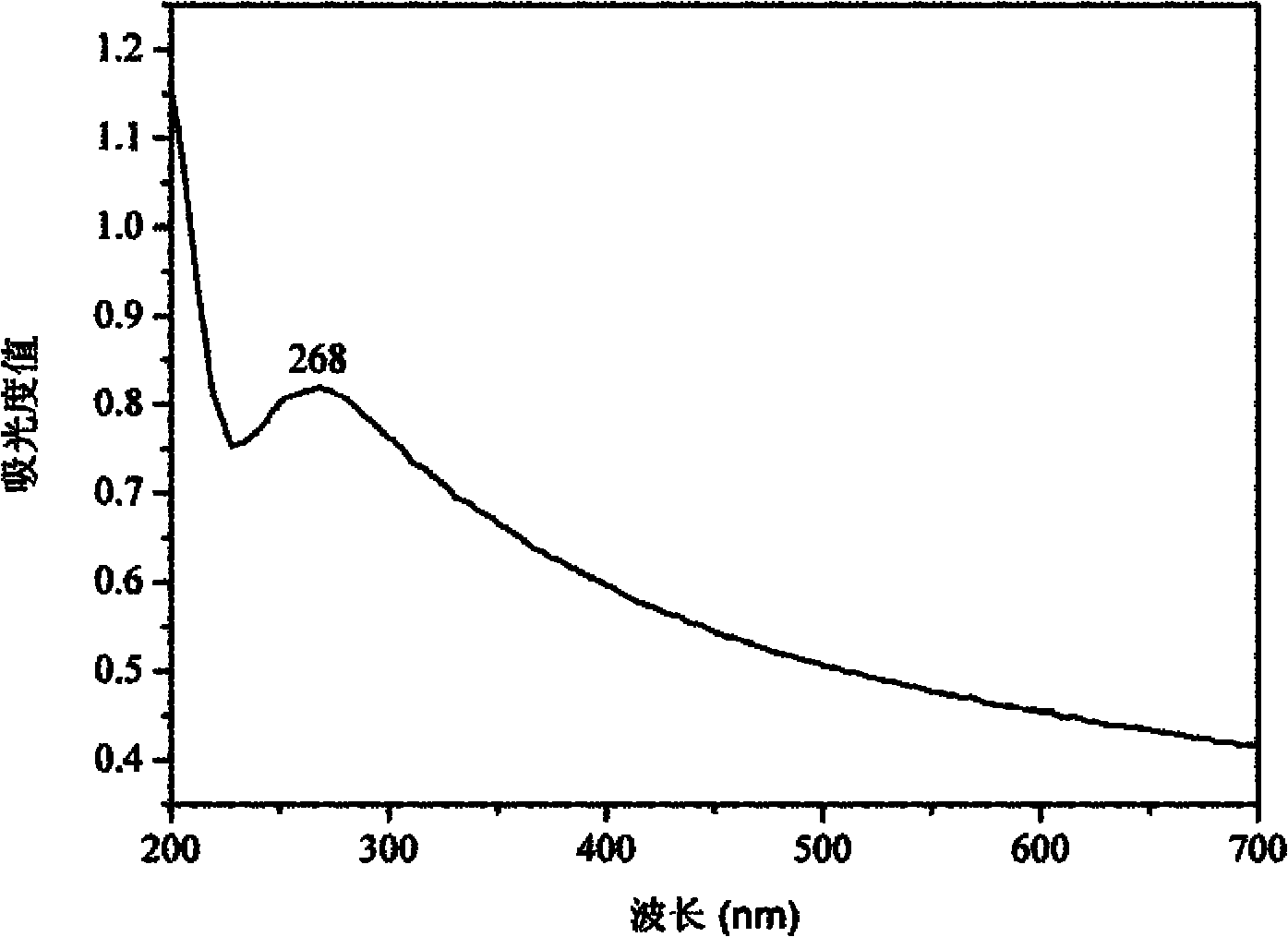

Embodiment 1

[0029] Disperse 20 mg of the above graphene oxide solid and 40 mg of polyvinylpyrrolidone in 20 ml of dimethylformamide, mix the two solutions evenly, and react at 160°C for 1 hour, cool to room temperature, filter with suction, and filter the cake Washing with a large amount of deionized water, the black product obtained is the graphene protected by polyvinylpyrrolidone, which can be dissolved in deionized water again to form a monolayer of graphene solution protected by polyvinylpyrrolidone.

Embodiment 2

[0031] Disperse 80 mg of the above-mentioned graphene oxide solid and 400 mg of polyvinylpyrrolidone in 20 ml of dimethylformamide, mix the two solutions evenly, and react at 140°C for 2 hours, cool to room temperature, suction filter, and filter cake Washing with a large amount of deionized water, the black product obtained is the graphene protected by polyvinylpyrrolidone, which can be dissolved in deionized water again to form a monolayer of graphene solution protected by polyvinylpyrrolidone.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com