Electronic grade citric acid and production method thereof

A citric acid, electronic grade technology, applied in the field of electronic grade citric acid and its production process, can solve the problem of reducing cation content and achieve the best market prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

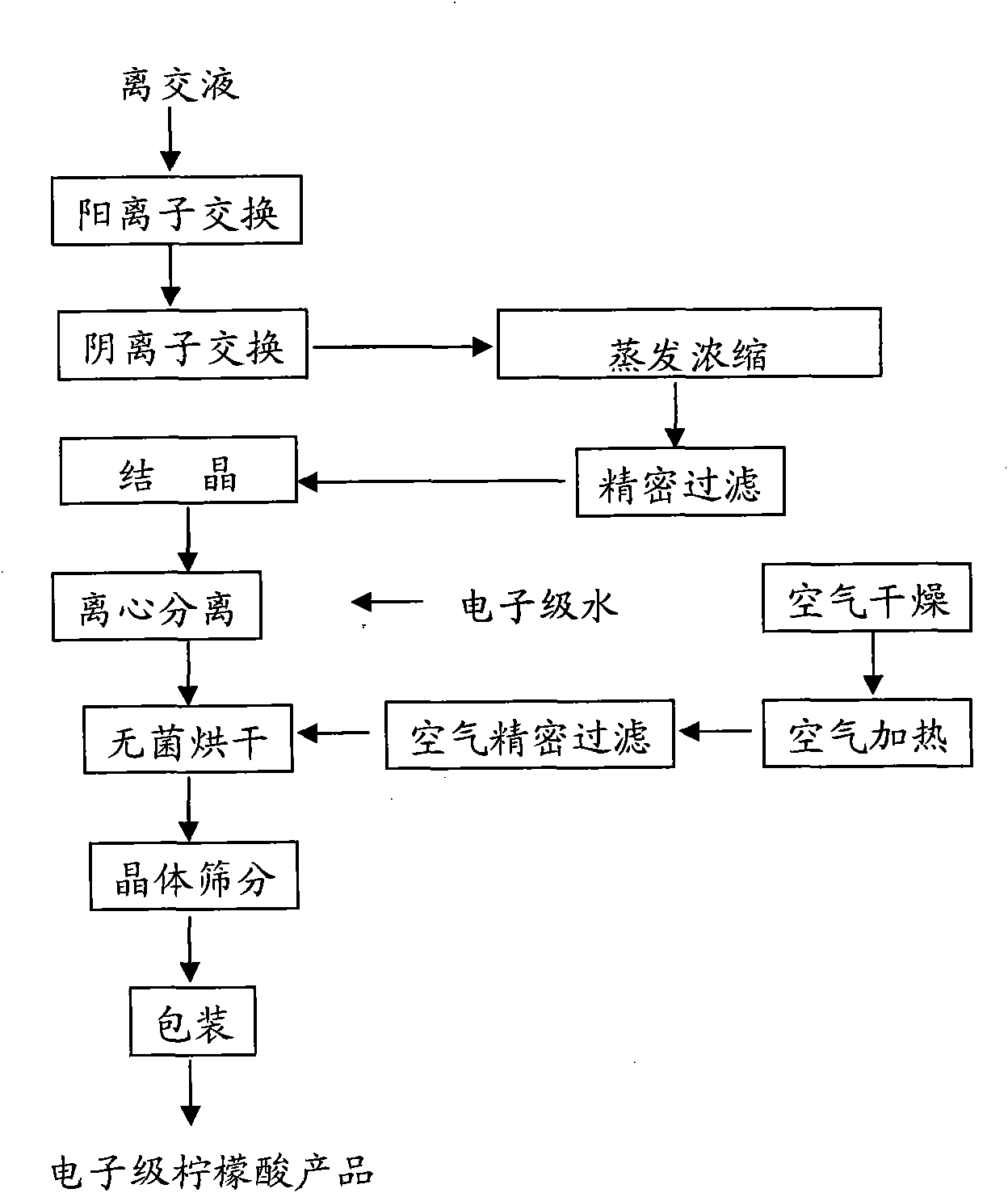

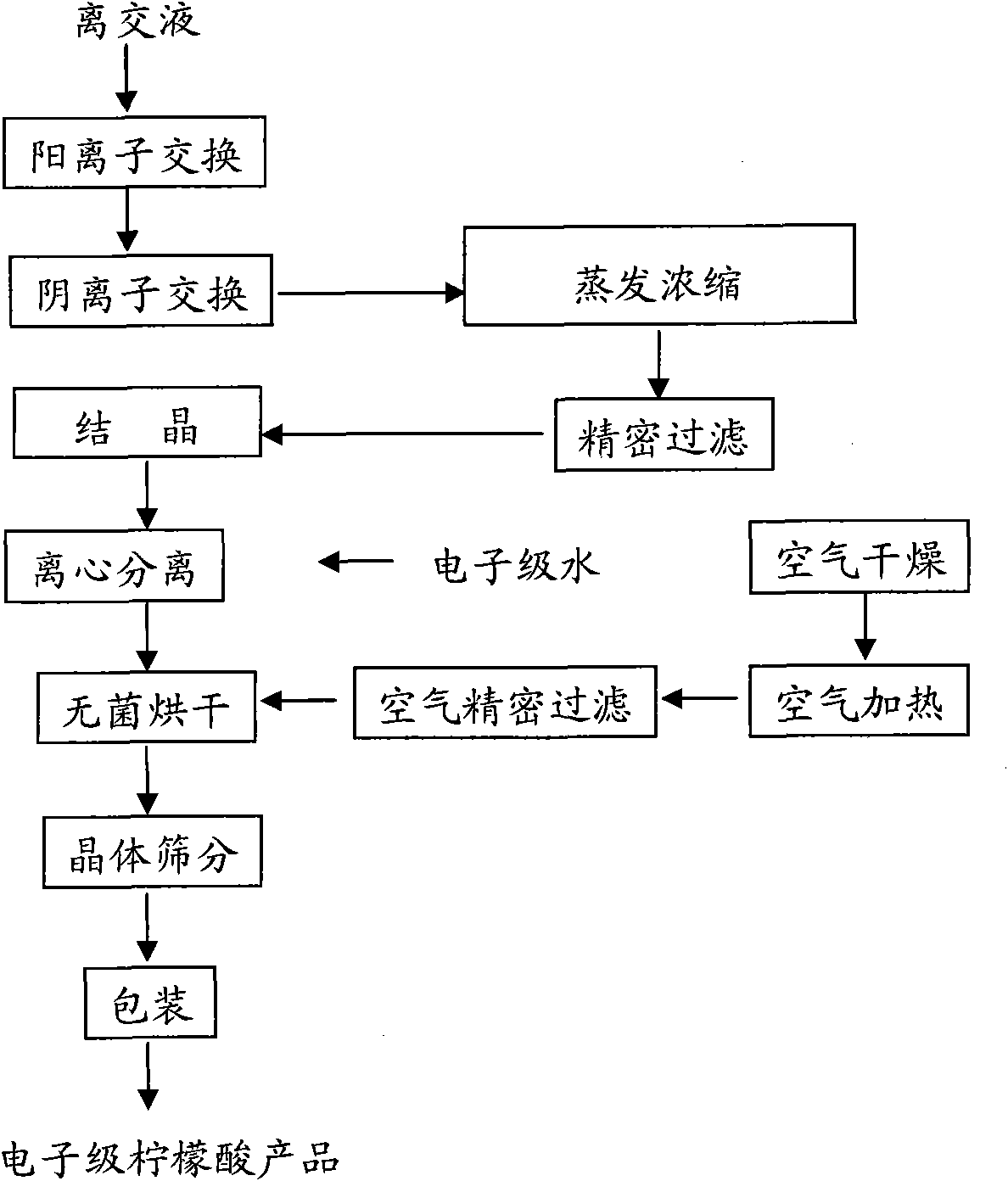

[0031] Pass the citric acid chaotropic liquid into a cation exchange column equipped with D-412 chelating resin, and the column loading steps are: adjust the temperature of the citric acid solution into the column to be 55° C., and the concentration of citric acid to be 35%. The citric acid solution flows in from the top of the positive column at a flow rate of 2BV / h. When the concentration of the outflowing citric acid solution is 0.2 times the concentration of the incoming column, start to collect the positive column ion exchange liquid, and detect the cation content of the material at any time. When the outflow solution When the potassium ion content reaches 1μg / g, the collection is stopped, and the positive column fails at this time. After the cation exchange resin fails, use reagent grade hydrochloric acid or sulfuric acid to configure regeneration acid, and the process water uses electronic grade ultrapure water.

[0032]Pass the ion exchange liquid from the cation excha...

Embodiment 2

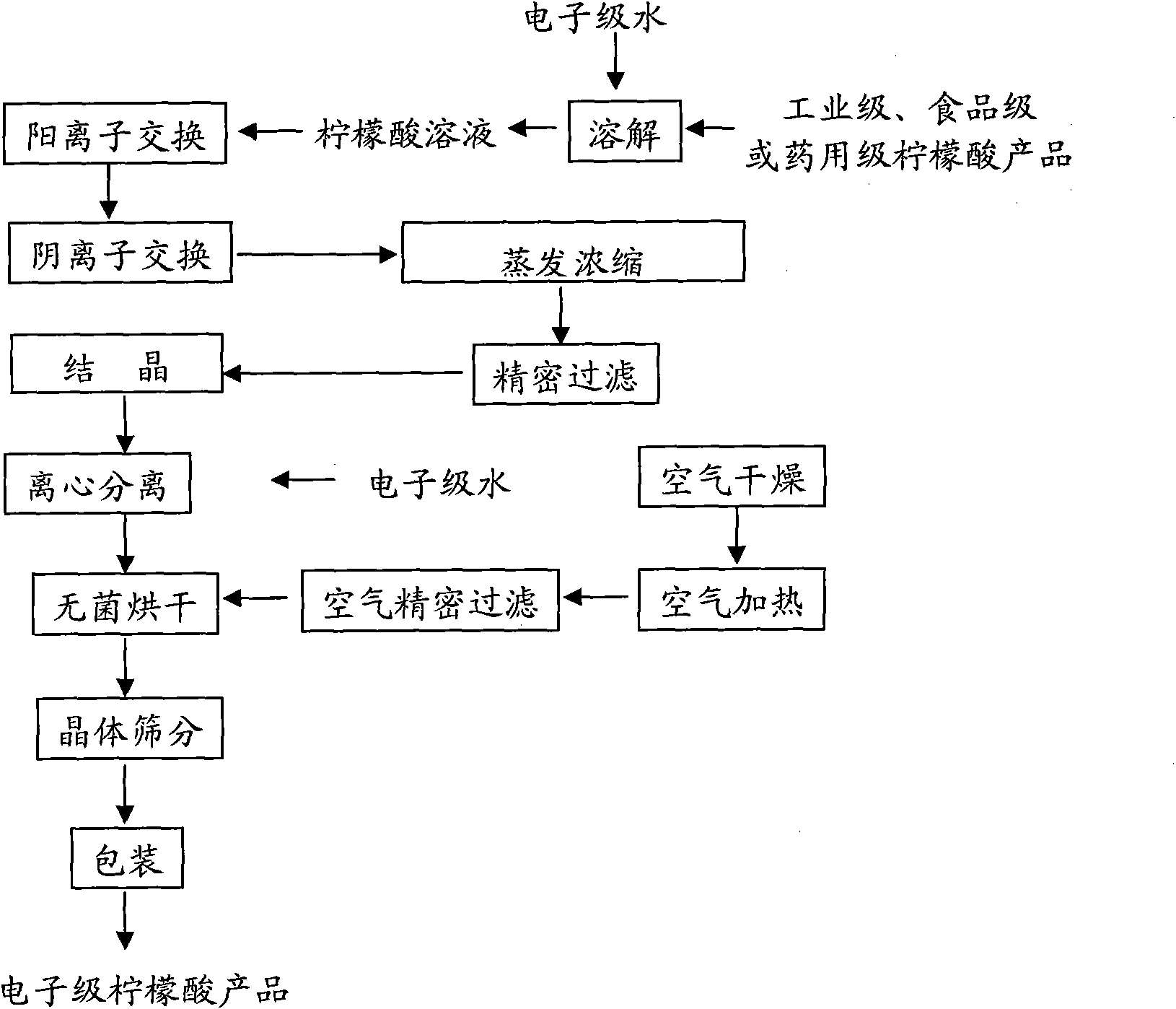

[0036] Pass the industrial grade citric acid solution into a cation exchange column equipped with D-412 chelating resin, and the column loading steps are as follows: adjust the temperature of the citric acid solution into the column to be 60° C., and the concentration of citric acid to be 40%. The citric acid solution flows in from the top of the positive column at a flow rate of 3BV / h. When the concentration of the citric acid solution flowing out is 0.5 times the concentration of the incoming column, start to collect the positive column ion exchange liquid, and detect the cation content of the material at any time. When the potassium ion content reaches 1μg / g, the collection is stopped, and the positive column fails at this time. After the cation exchange resin fails, use reagent grade hydrochloric acid or sulfuric acid to configure regeneration acid, and the process water uses electronic grade ultrapure water.

[0037] Pass the ion exchange liquid from the cation exchange c...

Embodiment 3

[0041] The food-grade citric acid solution is passed into a D-412 chelating resin cation exchange column, and the column loading step is as follows: adjust the temperature of the citric acid solution into the column to be 55 ° C, the concentration of citric acid is 40%, and the citric acid solution is added at 1.5 The flow rate of BV / h flows in from the top of the positive column. When the concentration of the outflowing citric acid solution is equal to the concentration of the incoming column, start to collect the ionized liquid of the positive column, and detect the cation content of the outgoing material at any time. When the potassium ion content of the outflow solution reaches 1μg / g , stop collecting, and the Yang column will fail at this time. After the cation exchange resin fails, use reagent grade hydrochloric acid or sulfuric acid to configure regeneration acid, and the process water uses electronic grade ultrapure water.

[0042] Pass the ion exchange liquid from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com