Method for extracting usnic acid from sun-lo

A technology of usnic acid and usnea, applied in the direction of organic chemistry, can solve the problems of great harm to operators, excessive use of organic toxic reagents, serious environmental pollution, etc., to solve the problem of difficult resin adsorption, reduce costs, and ensure safe operation of personnel sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

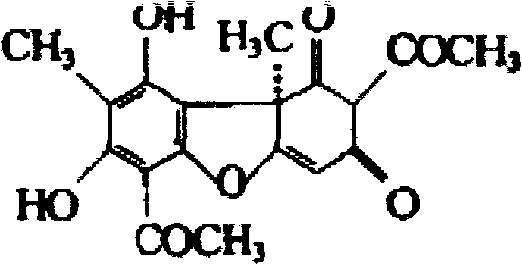

Image

Examples

Embodiment 1

[0024] Take Usnea raw material, pick and remove impurities and crush it, weigh 1kg and put it into a stainless steel multifunctional small extraction tank, take 130g of sodium bicarbonate and add appropriate amount of water to dissolve, take ethanol to make a 6L90% solution, add it to the extraction tank and reflux for 1 hour, extract three times, and combine The extract reclaims ethanol, adds an appropriate amount of water to disperse to obtain the upper column liquid, takes 200ml001×7 cationic resin, treats it with 2% sodium hydroxide solution and 3% hydrochloric acid solution successively, washes the neutral column with water, and treats 500mlD101 macroporous resin in the same way, Two resin columns are connected in series, the upper column solution is added to the resin column, the flow rate is controlled at 3L / h, and the adsorption is repeated 3 times. After the adsorption is completed, 4.5L of 50% ethanol solution is taken to elute the macroporous resin column, and the elu...

Embodiment 2

[0026] Take Usnea raw material, pick and remove impurities and crush, weigh 1kg and put it into a stainless steel multi-functional small extraction tank, take 200g sodium carbonate and add appropriate amount of water to dissolve, take ethanol to make a 10L 70% solution, add it to the extraction tank and reflux for 1 hour, extract three times, and combine the extraction Recover ethanol from liquid, add appropriate amount of water to disperse to get upper column liquid, take 200ml D301 cationic resin, treat with 2% sodium hydroxide solution and 3% hydrochloric acid solution successively, wash neutral column with water, treat 500ml AB-8 macroporous resin in the same way , two resin columns are connected in series, the upper column solution is added to the resin column, the flow rate is controlled at 4L / h, and the adsorption is repeated 4 times. After the adsorption is completed, 2.5L of 90% ethanol solution is taken to elute the macroporous resin column, and the eluent recovers eth...

Embodiment 3

[0028] Take Usnea raw material, pick and remove impurities and crush it, weigh 1kg and put it into a stainless steel multifunctional small extraction tank, take 150g of sodium bicarbonate and add appropriate amount of water to dissolve, take ethanol and configure it into a 15L85% solution, add it to the extraction tank for reflux for 2 hours, and extract twice, Combine the extracts to recover ethanol, add an appropriate amount of water to disperse to obtain the upper column liquid, take 200ml D113 cationic resin, treat it with 2% sodium hydroxide solution and 3% hydrochloric acid solution successively, wash the neutral column with water, and treat 500ml X-5 large Porous resin, two resin columns connected in series, add the upper column liquid into the resin column, control the flow rate at 5L / h, repeat the adsorption 5 times, after the adsorption is completed, take 3.5L of 750% ethanol solution to elute the macroporous resin column, and the eluent is recovered Ethanol to 40% le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com