Production method of succinate starch for food industry

A technology of succinate ester and production method, which is applied in the field of modified starch and its production, can solve the problems of less production and application of succinate starch, and achieve the goal of promoting planting and production development, low gelatinization temperature, and high bonding strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

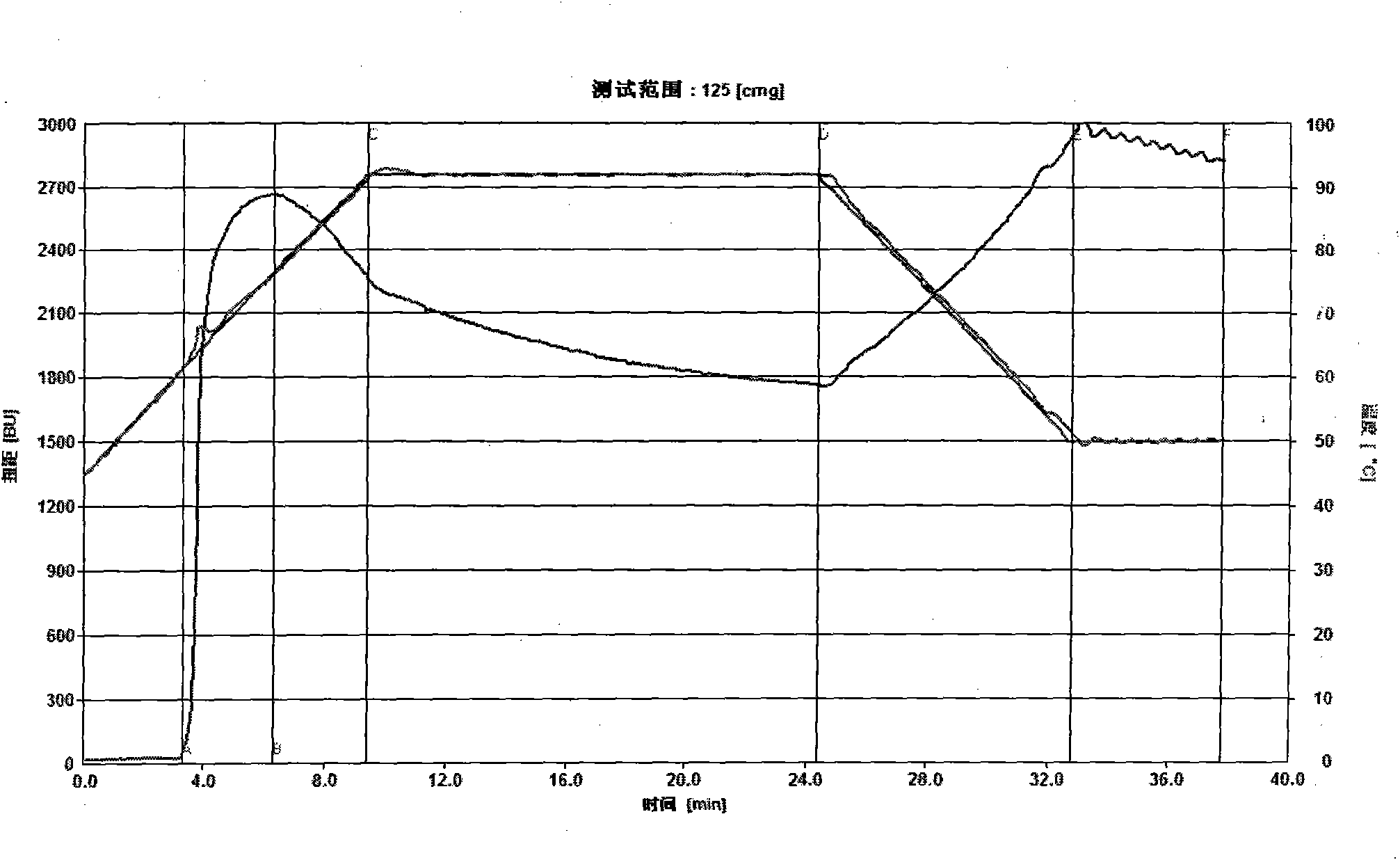

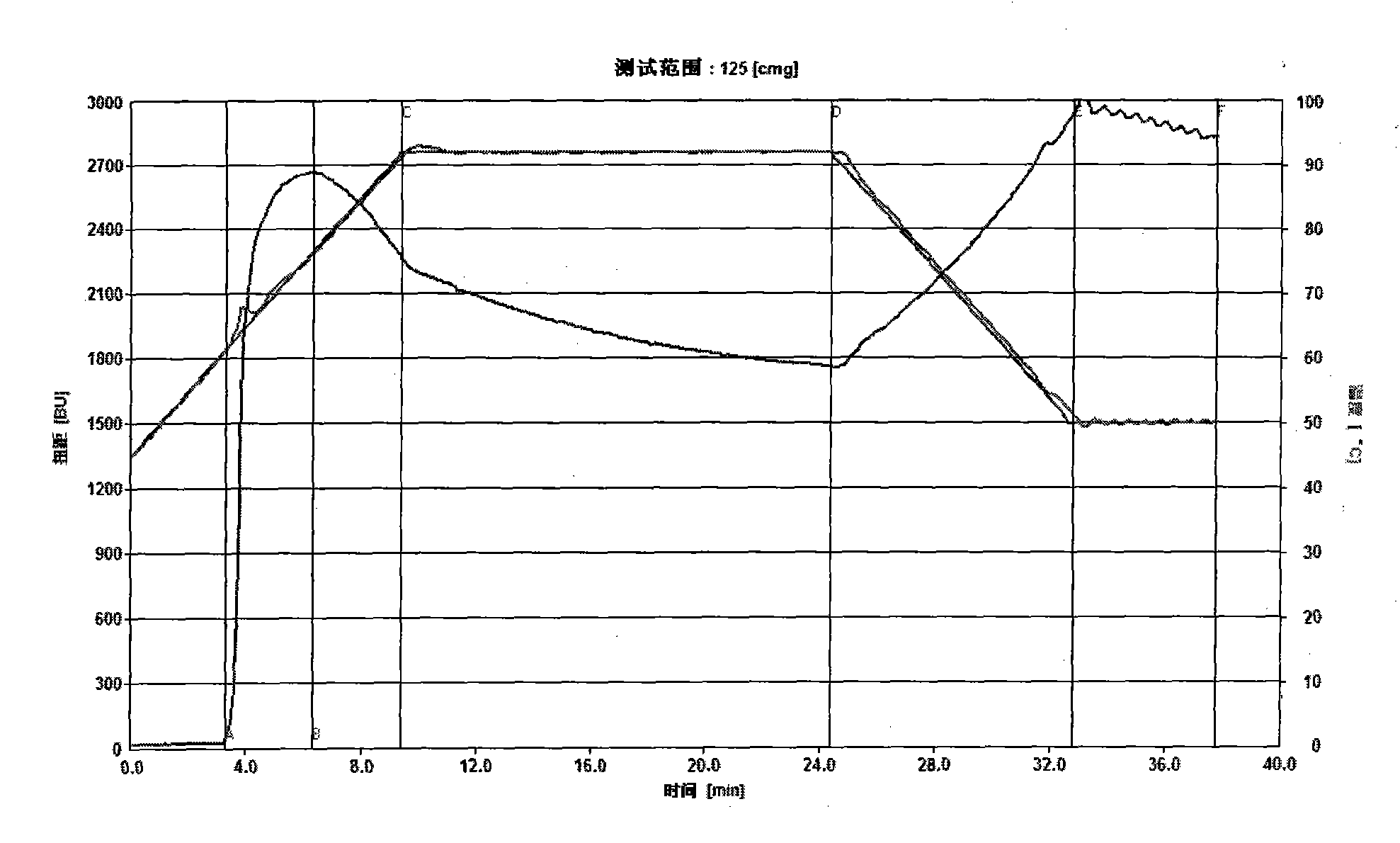

Image

Examples

Embodiment 1

[0038] The raw cassava starch is adjusted to 35-40% starch slurry with water, and the starch content is 10 tons. Add 100kg of sodium sulfate to the starch slurry, add 3% potassium hydroxide aqueous solution to adjust the pH value of the slurry to 10-11, add 40kg of sodium trimetaphosphate, heat up to the temperature of the slurry at 40-50°C, and keep the temperature for 1-3 hours; then use Aqueous hydrochloric acid solution adjusts the pH value of the slurry to 8-10, cools the slurry to 25-35°C, adds 100kg of succinic anhydride, and simultaneously adds 3% potassium hydroxide aqueous solution to keep the pH value of the slurry at 8-10, the reaction temperature is 25-35°C, and the reaction time for 0.5-1 hour, then adjust the pH value of the slurry to 5-7 with hydrochloric acid aqueous solution, and obtain the product through processes such as washing, centrifugal dehydration, drying, screening, and packaging.

Embodiment 2

[0040] The raw sweet potato starch is adjusted into a starch slurry with a concentration of 35-40% with water, and the starch content is 10 tons. Add 200kg of sodium sulfate to the starch slurry, add 4% sodium hydroxide aqueous solution to adjust the pH value of the slurry to 10-11, add 20kg of sodium trimetaphosphate, heat up to the temperature of the slurry at 40-50°C, and keep the temperature for reaction for 1-3 hours; then use Sulfuric acid aqueous solution adjusts the pH value of the slurry to 8-10, cools the slurry to 25-35°C, adds 150kg of succinic anhydride, and simultaneously adds 4% sodium hydroxide aqueous solution to maintain the pH value of the slurry to 8-10, the reaction temperature is 25-35°C, and the reaction time for 0.5-1 hour, then adjust the pH value of the slurry to 5-7 with sulfuric acid aqueous solution, and obtain the product through processes such as washing, centrifugal dehydration, drying, screening, and packaging.

Embodiment 3

[0042] The raw cassava starch is adjusted to 35-40% starch slurry with water, and the starch content is 10 tons. Add 300 kg of sodium chloride to the starch slurry, add 5% aqueous sodium hydroxide solution to adjust the pH value of the slurry to 10-11, add 5 kg of sodium trimetaphosphate, raise the temperature to the slurry temperature of 40-50 ° C, and keep the temperature for 1-3 hours; then Adjust the pH value of the slurry to 8-10 with aqueous hydrochloric acid, cool the slurry to 25-35°C, add 200kg of succinic anhydride, and add 5% aqueous sodium hydroxide solution to keep the pH of the slurry at 8-10, and the reaction temperature is 25-35°C. The time is 0.5-1 hour, and then the pH value of the slurry is adjusted to 5-7 with hydrochloric acid aqueous solution, and the product is obtained through processes such as washing, centrifugal dehydration, drying, screening, and packaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com