Vinylester resin stone adhesive and preparation method thereof

The technology of vinyl ester resin and adhesive is applied in the field of vinyl ester resin stone adhesive and its preparation. Low cost and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] According to the proportioning in parts by mass, get 51 parts of bisphenol A type epoxy resin, 15 parts of methacrylic acid, 33 parts of styrene, 0.85 part of benzoquinone, 0.15 part of benzyldimethylamine; Bisphenol A epoxy resin, Put benzyldimethylamine and hydroquinone into the reaction kettle, vacuumize, stir and heat up, and control the temperature at 120°C to 140°C for 3 hours until the acid value drops below 20mgKOH / g; cool the reaction product to Below 110°C, add styrene to dilute, lower the temperature to room temperature, filter and stir evenly to obtain vinyl ester resin. Take 50 parts of p-phenylene unsaturated polyester resin and 50 parts of vinyl ester resin and stir evenly to prepare vinyl ester resin mixed resin for later use. Used in Examples 2-4 below.

Embodiment 2

[0040] Formula by mass percentage:

[0041] A component B component

[0042] Vinyl ester resin mixed resin: 55% Methyl ethyl ketone peroxide: 30%

[0043] Cobalt naphthenate: 0.4% Dibutyl phthalate: 30%

[0044] N, N-dimethylaniline: 0.4% Aluminum hydroxide: 40%

[0045] Petroleum resin: 1.5%

[0046] Benzoquinone: 0.1%

[0047] Aluminum hydroxide: 40%

[0048] KH-570: 1.0%

[0049] Titanium dioxide: 1.5%

[0050] BYK-501: 0.1%.

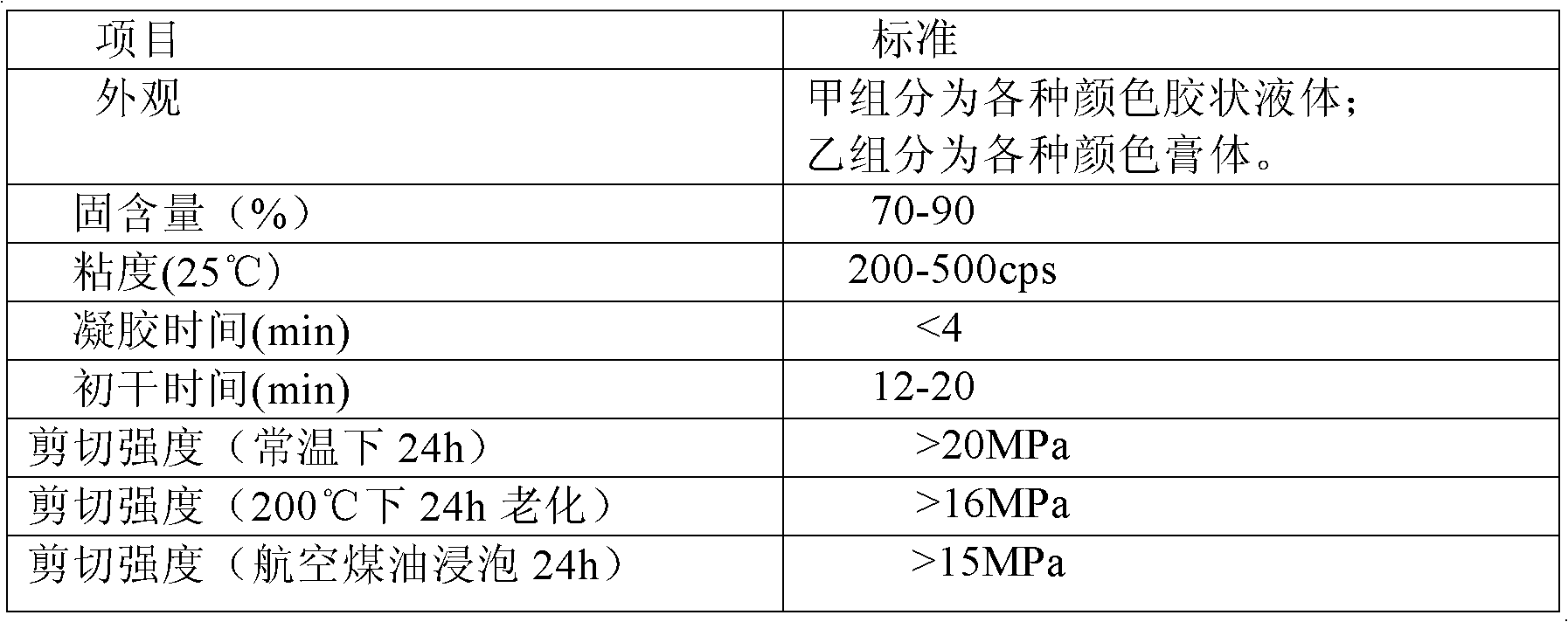

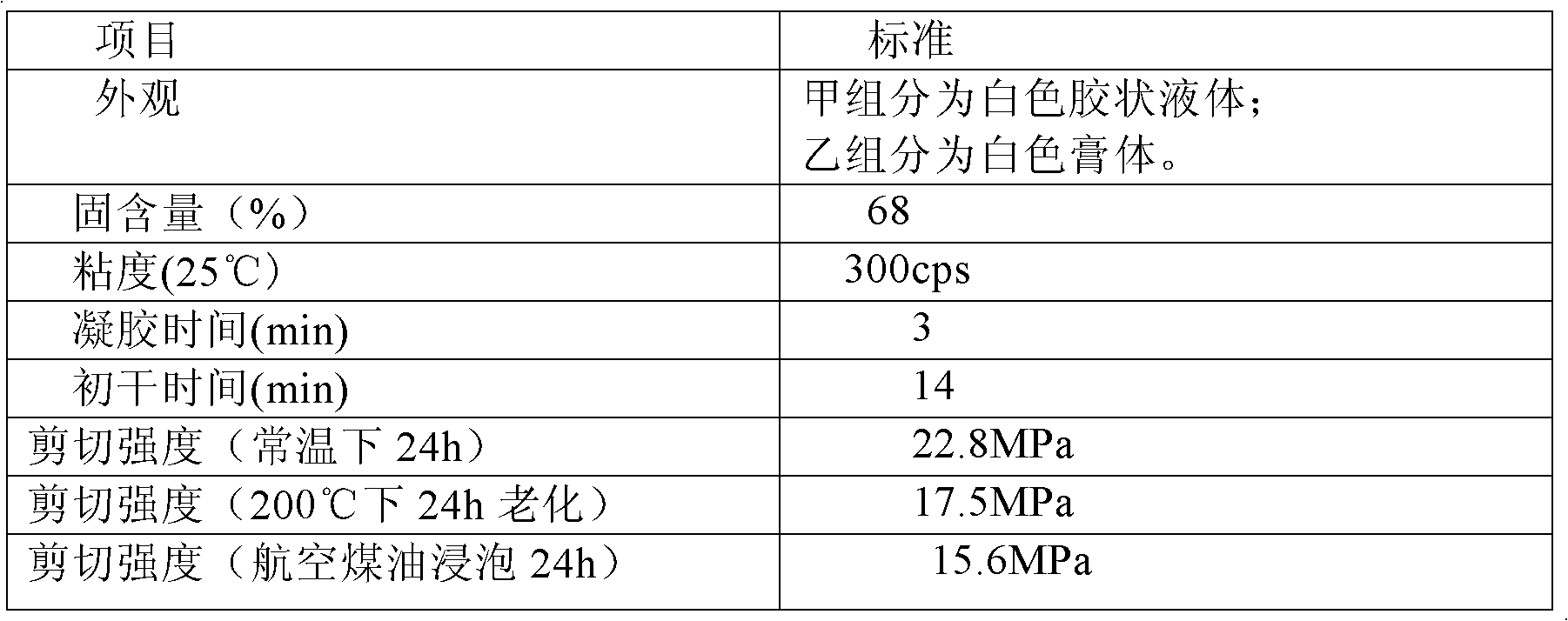

[0051] The technical parameters are:

[0052]

Embodiment 3

[0054] A component B component

[0055]Vinyl ester resin mixed resin: 57% Cyclohexanone peroxide: 35%

[0056] Cobalt naphthenate: 0.3% Dibutyl phthalate: 35%

[0057] N, N-diethylaniline: 0.3% Aluminum hydroxide: 30%

[0058] Organic bentonite: 1.6%

[0059] Aluminum hydroxide: 40%

[0060] Tert-Butylcatechol: 0.1%

[0061] KH-550: 0.5%

[0063] BYK-501: 0.1%.

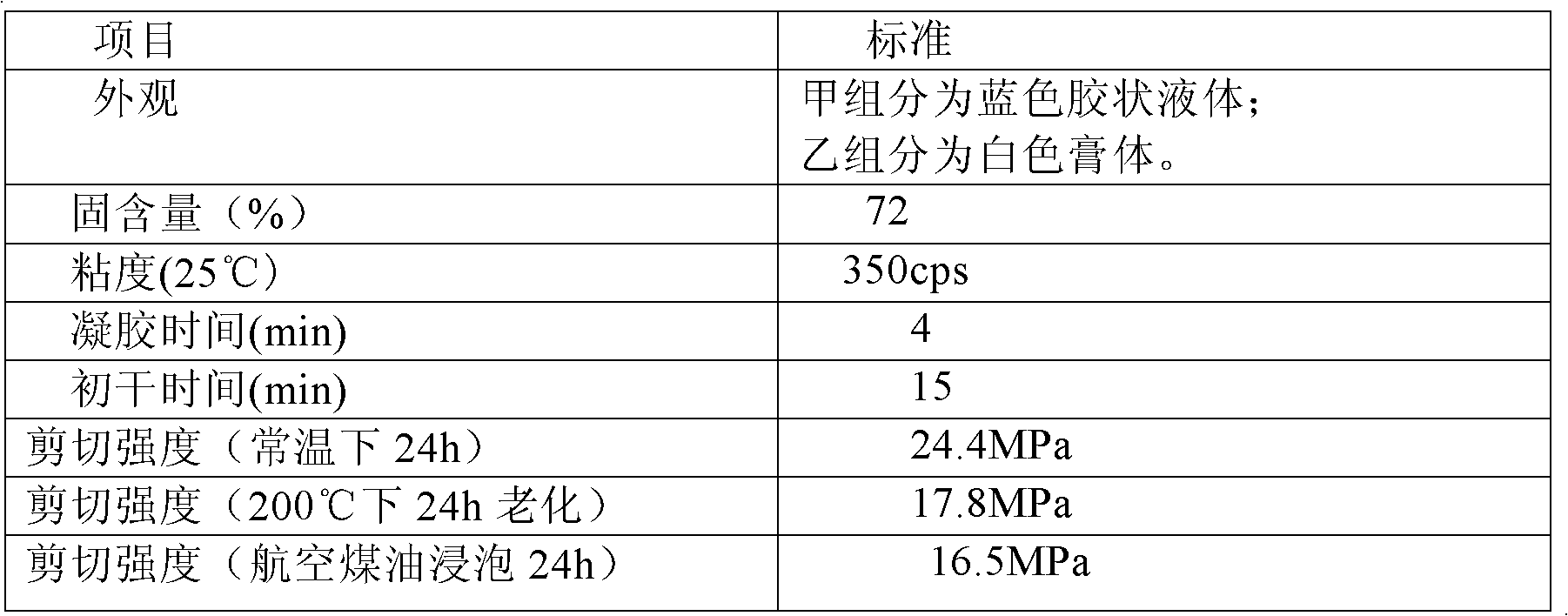

[0064] The technical parameter of formula 3 is:

[0065]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com