Preparation method of superhydrophobic self-cleaning material

A self-cleaning, super-hydrophobic technology, applied in chemical instruments and methods, fibrous fillers, inorganic pigment treatment, etc., can solve problems such as easy to be damaged by external forces, expensive fluorosilicon compounds, and poor mechanical strength of the surface microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

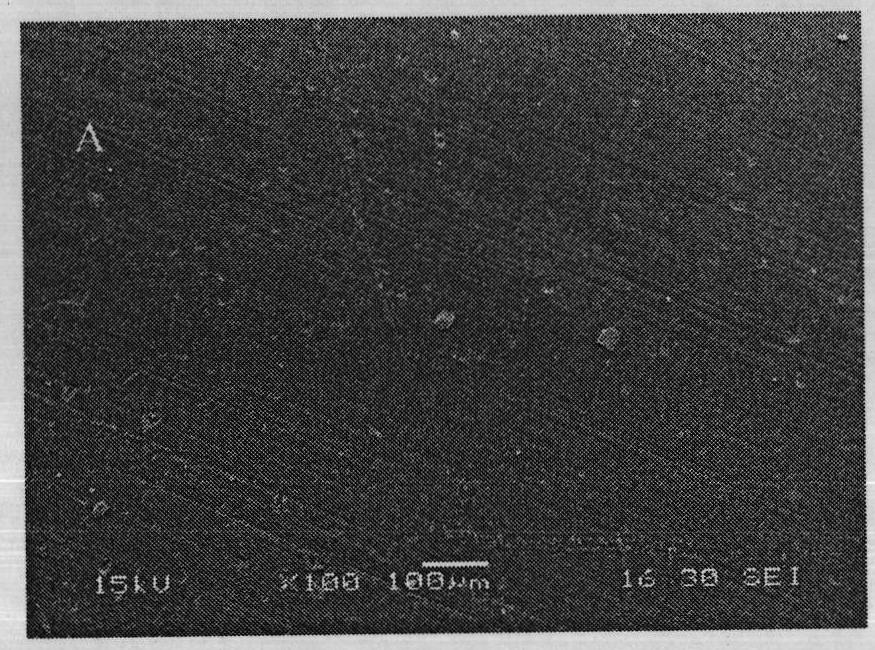

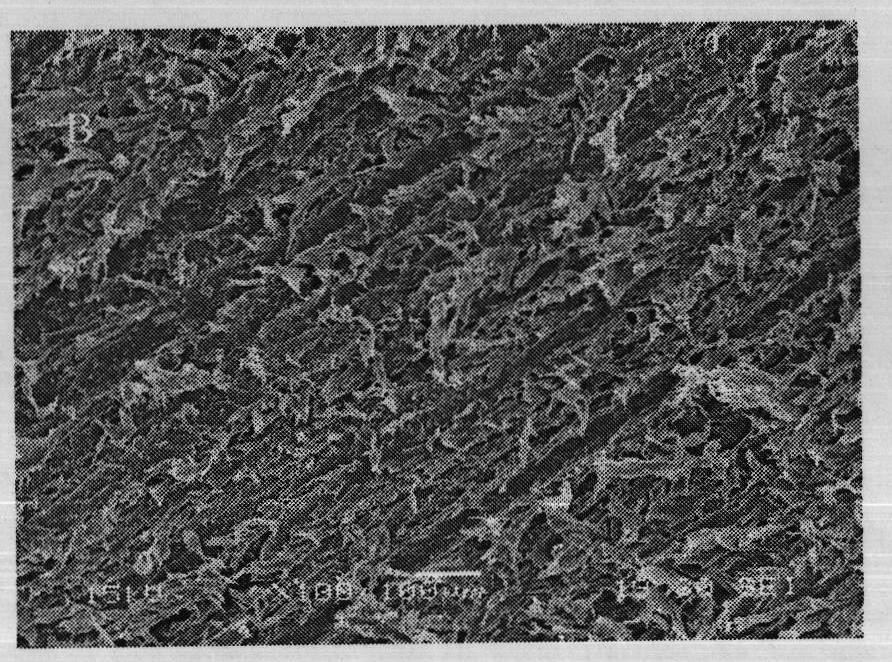

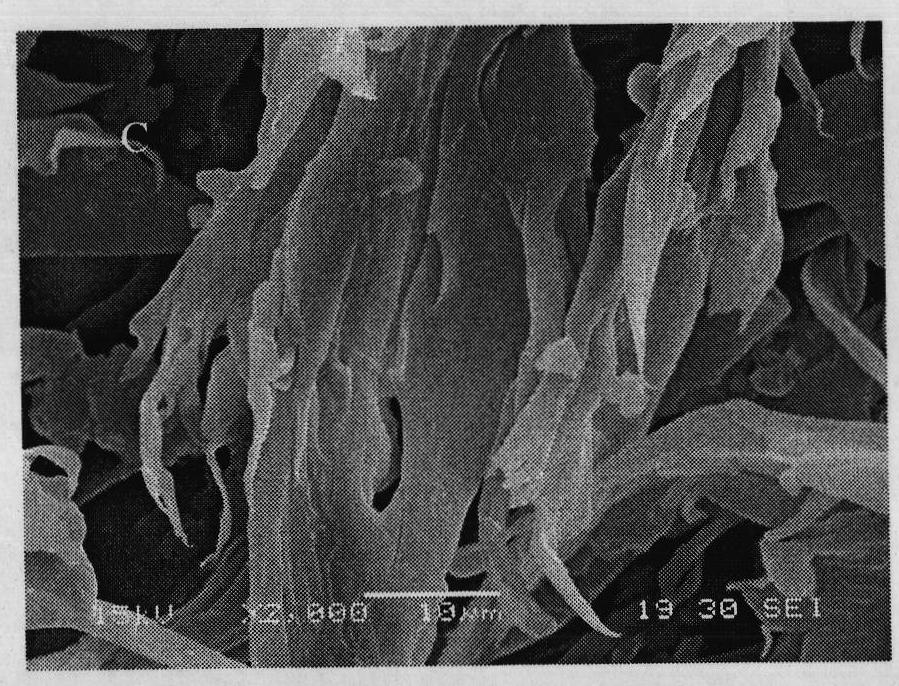

Image

Examples

Embodiment 1

[0031] 1) Silicone rubber and vulcanizing agent (Double Two Five) were kneaded on a two-roll mill (at a temperature of 20° C.) for 5 minutes at a ratio of 100:0.5 in parts by mass. Set aside the premixed glue for later use.

[0032] 2) fluorinating graphite. Prepare the mixed gas of fluorine and nitrogen with a fluorine concentration of 5% (volume fraction); dry the graphite in the reactor at 50°C for 10 hours in vacuum, continuously fill with nitrogen, and vacuumize to ensure that there is no carbon dioxide before the reaction. Oxygen: Introduce the mixed gas of fluorine and nitrogen into the reactor, the fluorination temperature is 0°C, and the treatment time is 3 hours. After the reaction is completed, vacuum and nitrogen are changed 10 times, and the fluorinated graphite is obtained after taking it out. (wherein: the gas extracted after the reaction is passed into alkaline water for harmless treatment.)

[0033] 3) Use the fluorinated graphite (5phr), premixed rubber (10...

Embodiment 2

[0038]1) Knead the silicone rubber (100Phr) and the vulcanizing agent (double 25) (1Phr) on a two-roll mill (at a temperature of 20°C) for 5 minutes. Set aside the premixed glue for later use.

[0039] 2) fluorinating graphite. Prepare the mixed gas of fluorine and nitrogen with fluorine concentration of 10% (volume fraction); dry the graphite in the reactor at 50°C for 10 hours in vacuum, continuously fill nitrogen, and vacuumize to ensure that there is no carbon dioxide before the reaction. Oxygen: introduce the mixed gas of fluorine and nitrogen into the reactor, the fluorination temperature is 10°C, and the treatment time is 5 hours. After the reaction is completed, vacuum and nitrogen are changed 10 times, and the fluorinated graphite is obtained after taking it out. (wherein: the gas extracted after the reaction is passed into alkaline water for harmless treatment.)

[0040] 3) fluorinated graphite (10phr), premixed rubber (15phr), polypropylene (100phr) and other addi...

Embodiment 3

[0045] 1) Mix silicone rubber (100Phr) and vulcanizing agent (double 25) (2Phr) on a two-roll mill (at a temperature of 20°C) for 10 minutes. Set aside the premixed glue for later use.

[0046] 2) fluorinating graphite. Prepare the mixed gas of fluorine and nitrogen with fluorine concentration of 10% (volume fraction); dry the graphite in the reactor at 50°C for 10 hours in vacuum, continuously fill nitrogen, and vacuumize to ensure that there is no carbon dioxide before the reaction. Oxygen: introduce the mixed gas of fluorine and nitrogen into the reactor, the fluorination temperature is 40°C, and the treatment time is 10 hours. After the reaction is completed, vacuum and nitrogen are changed 10 times, and the fluorinated graphite is obtained after taking it out. (wherein: the gas extracted after the reaction is passed into alkaline water for harmless treatment.)

[0047] 3) Extrude the fluorinated graphite (15phr), premixed rubber (20phr), polypropylene (100phr) and other...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com