Multipurpose environmental protection adhesive for industrial use

A multi-purpose, adhesive technology, applied in the direction of monocarboxylate copolymer adhesives, adhesive types, unsaturated alcohol copolymer adhesives, etc., can solve poor water resistance and moisture resistance, creep, Damage and other problems, to achieve the effect of not easy to deform and strong moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

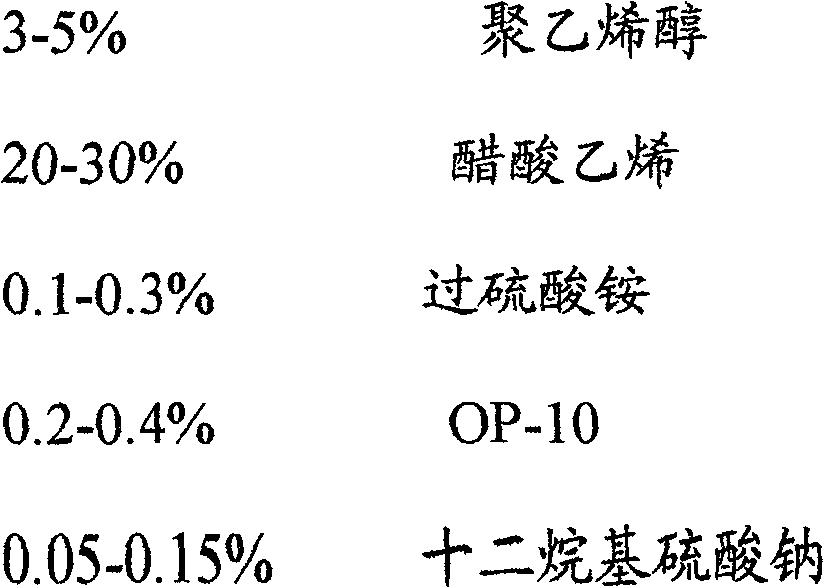

[0012] formula:

[0013]

[0014] Manufacturing process:

[0015] (1), add 450 kg of distilled water, start stirring, and slowly add polyvinyl alcohol (15 kg for 1788 model, 25 kg for 0588 model) in order.

[0016] (2) Put in sodium acetate and water-based defoamer, start to heat the reactor to 90 degrees Celsius, when the temperature is stable and maintain this temperature for 30 minutes, then drop to 70 degrees Celsius, add sodium lauryl sulfate and OP-10 , allow it to be fully emulsified, drop into methanol after 10 minutes, and put into initiator ammonium persulfate 0.04% (weight ratio) simultaneously, after 10 minutes, slowly drop the mixed vinyl acetate, acrylic acid, and butyl acrylate into the reactor.

[0017] (3), setting time is 4 hours, adds 0.05% (weight ratio) ammonium persulfate once every 30 minutes simultaneously, till adding.

[0018] (4) At this time, the heating reaction kettle is in a sealed state, and the steam in the reaction kettle is discharged in...

Embodiment 2

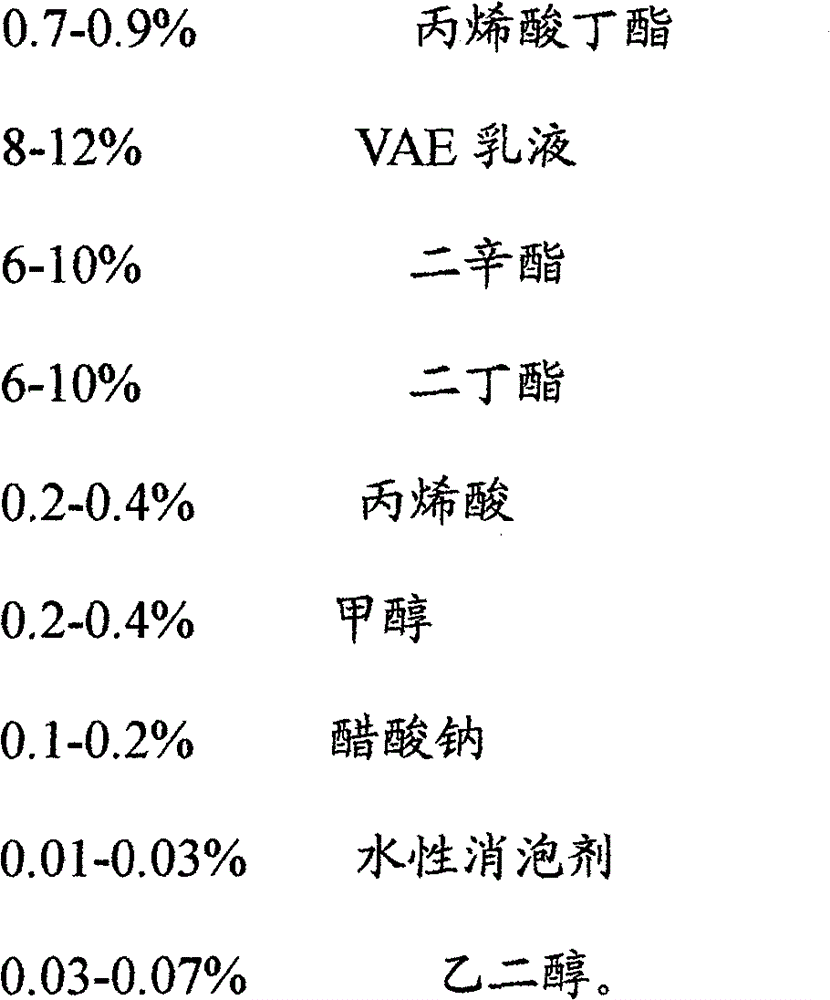

[0021] formula:

[0022]

[0023]

[0024] Manufacturing process:

[0025] (1), add 450 kg of distilled water, start stirring, and slowly add polyvinyl alcohol (15 kg for 1788 model, 25 kg for 0588 model) in order.

[0026] (2) Put in sodium acetate and water-based defoamer, start to heat the reactor to 90 degrees Celsius, when the temperature is stable and maintain this temperature for 30 minutes, then drop to 70 degrees Celsius, add sodium lauryl sulfate and OP-10 , allow it to be fully emulsified, drop into methanol after 10 minutes, and put into initiator ammonium persulfate 0.04% (weight ratio) simultaneously, after 10 minutes, slowly drop the mixed vinyl acetate, acrylic acid, and butyl acrylate into the reactor.

[0027] (3), setting time is 4 hours, add 0.05% ammonium persulfate (weight ratio) once every 30 minutes simultaneously, until adding.

[0028] (4) At this time, the heating reaction kettle is in a sealed state, and the steam in the reaction kettle is d...

Embodiment 3

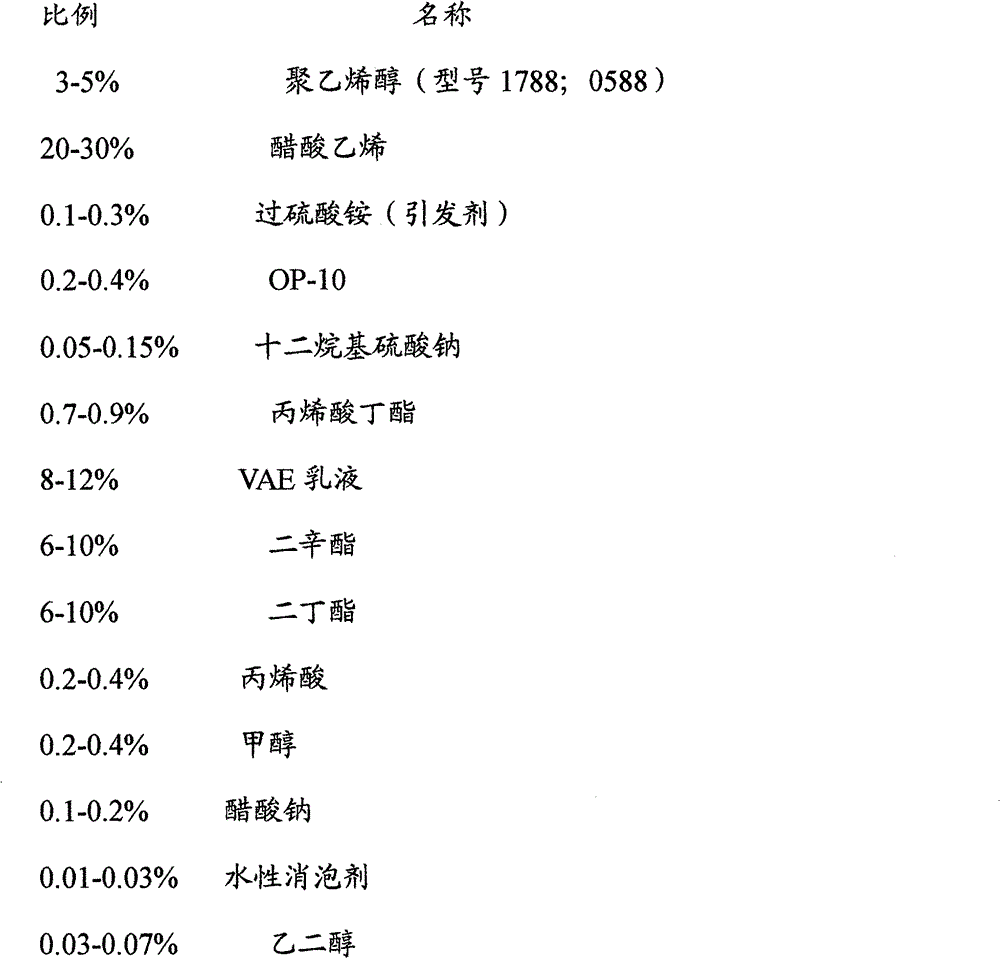

[0031] formula:

[0032]

[0033]

[0034] Manufacturing process:

[0035] (1), add 450 kg of distilled water, start stirring, and slowly add polyvinyl alcohol (15 kg for 1788 model, 25 kg for 0588 model) in order.

[0036] (2) Put in sodium acetate and water-based defoamer, start to heat the reactor to 90 degrees Celsius, when the temperature is stable and maintain this temperature for 30 minutes, then drop to 70 degrees Celsius, add sodium lauryl sulfate and OP-10 , allow it to be fully emulsified, drop into methanol after 10 minutes, and put into initiator ammonium persulfate 0.04% (weight ratio) simultaneously, after 10 minutes, slowly drop the mixed vinyl acetate, acrylic acid, and butyl acrylate into the reactor.

[0037] (3), setting time is 4 hours, add 0.05% ammonium persulfate (weight ratio) once every 30 minutes simultaneously, till adding.

[0038] (4) At this time, the heating reaction kettle is in a sealed state, and the steam in the reaction kettle is di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com