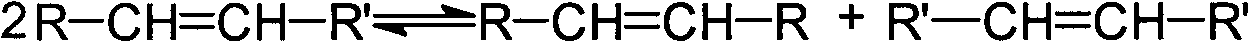

Catalyst for preparing propylene from butane and ethylene and preparation method thereof

A technology for producing propylene and catalyst from butene is applied in molecular sieve catalysts, chemical instruments and methods, catalysts for physical/chemical processes, etc. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

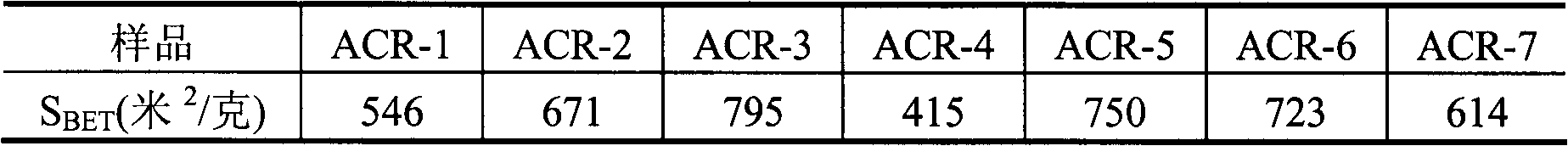

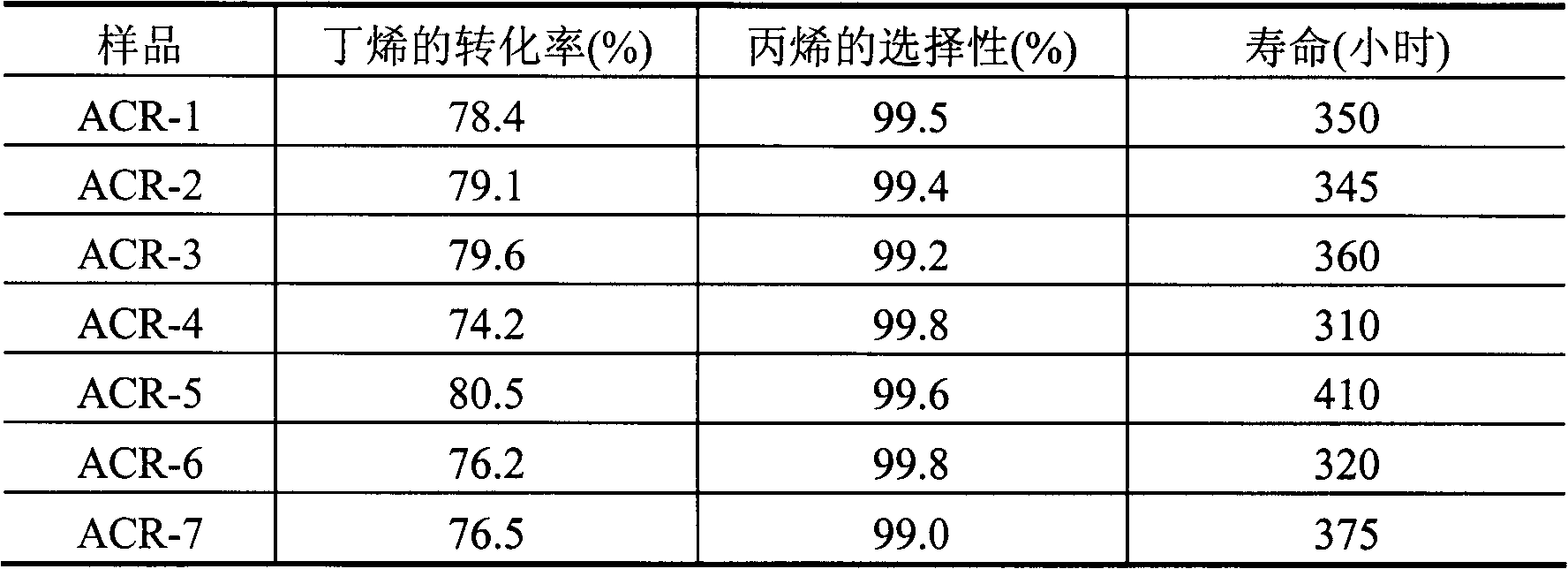

Embodiment 1

[0027] MCM-48 was prepared by a conventional method, and the average pore diameter of MCM-48 was 2.8 nanometers. Take 600 grams of MCM-48 with 200 grams of SiO 2 Mix to prepare a mixed carrier C with a certain particle size.

[0028] Mix 800 grams of carrier C and 1% scallop powder and put them into the mixer evenly, after stirring for 45 minutes, add the required 5% silica sol and 24 grams of ammonium metatungstate, then add 800 grams of deionized water, knead, After extrusion and drying, it was calcined at 550°C for 4 hours to obtain a disproportionation catalyst, which was designated as ACR-1. The evaluation of the catalyst was carried out on an olefin disproportionation evaluation device. Calculated by mass fraction, the main components of the raw material include: 5.37% butene-1, 57.27% butene-2 and the balance of n-butane. The reaction is at a temperature of 300°C, a pressure of 3MPa, and a molar ratio of ethylene to butene of 3 and 4.8 hours -1 The evaluation was c...

Embodiment 2

[0030] The SBA-15 is prepared by a conventional method, and the average pore diameter of the SBA-15 is 9.5 nanometers. Take 800 grams of SBA-15 and 50 grams of SiO 2 Mix to prepare a mixed carrier C with a certain particle size.

[0031] Mix 850 grams of carrier C and 1% scallop powder and put them into the mixer evenly. After stirring for 45 minutes, add the required 5% silica sol and 180 grams of ammonium metatungstate, then add 850 grams of deionized water, knead, After extrusion and drying, it was calcined at 450°C for 8 hours to obtain a disproportionation catalyst, which was designated as ACR-2. The evaluation conditions are the same as in Example 1, and the evaluation results are shown in Table 2.

Embodiment 3

[0033] The MSU-x was prepared by a conventional method, and the average pore diameter of the MSU-x was 3.7 nanometers. Take 100 grams of MSU-x with 650 grams of SiO 2 Mix to prepare a mixed carrier C with a certain particle size.

[0034] Mix 750 grams of carrier C and 1% scallop powder and put them into the mixer evenly, after stirring for 45 minutes, add the required 5% silica sol and 60 grams of ammonium metatungstate, then add 750 grams of deionized water, knead, The catalyst precursor M was prepared by extruding, drying and calcining at 650° C. for 2 hours. Put 200 grams of magnesium oxide into a blender and stir, and add the required amount of 1% scallop powder, 5% silica sol and 40 grams of deionized water, stir for 30 minutes, knead, extrude, dry and roast at 550°C Catalyst precursor Y was produced in 6 hours. Mix M and Y evenly and record it as ACR-3. The evaluation conditions are the same as in Example 1, and the evaluation results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com