Method for preparing strontium magnetic solid super acidic catalyst by immersing and baking method

A solid super acid and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, carboxylate preparation, etc., can solve the problems of narrow application scope, complex preparation process steps, difficult recovery and other problems, and achieve extended application fields , The process steps are simple, and the effect of expanding the demand area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

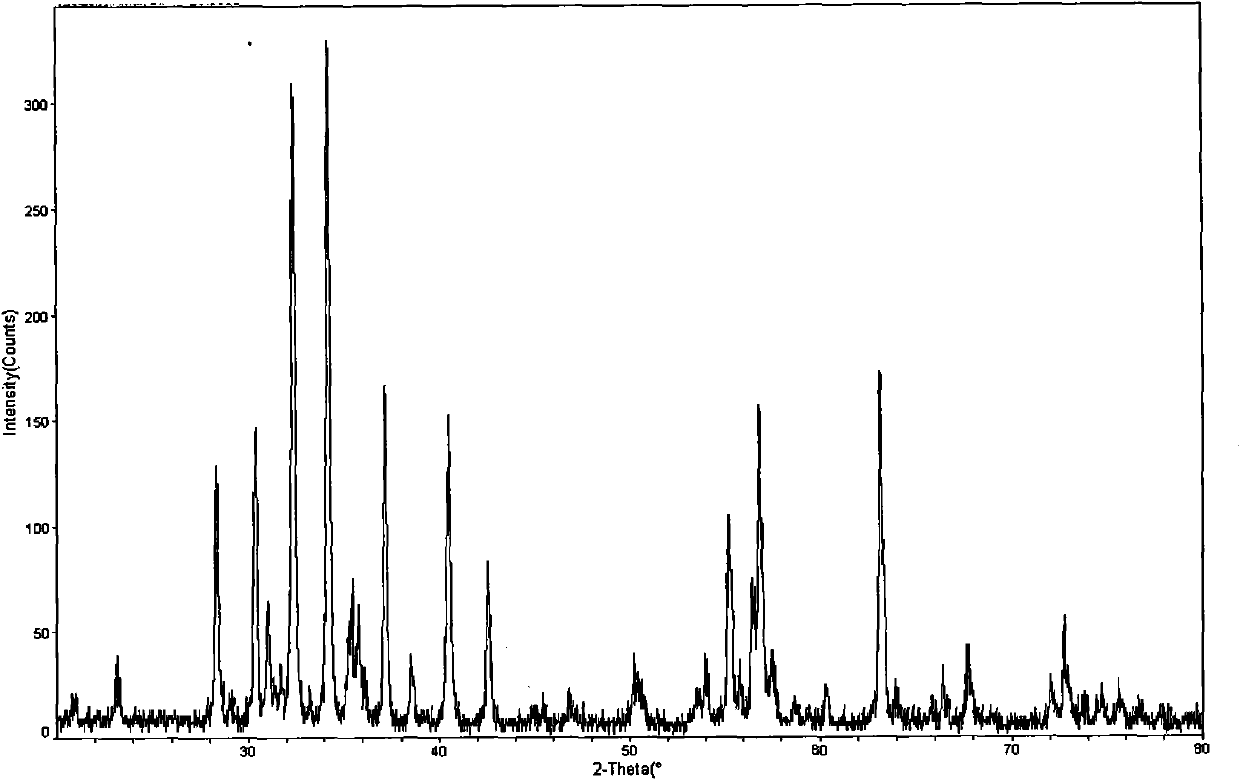

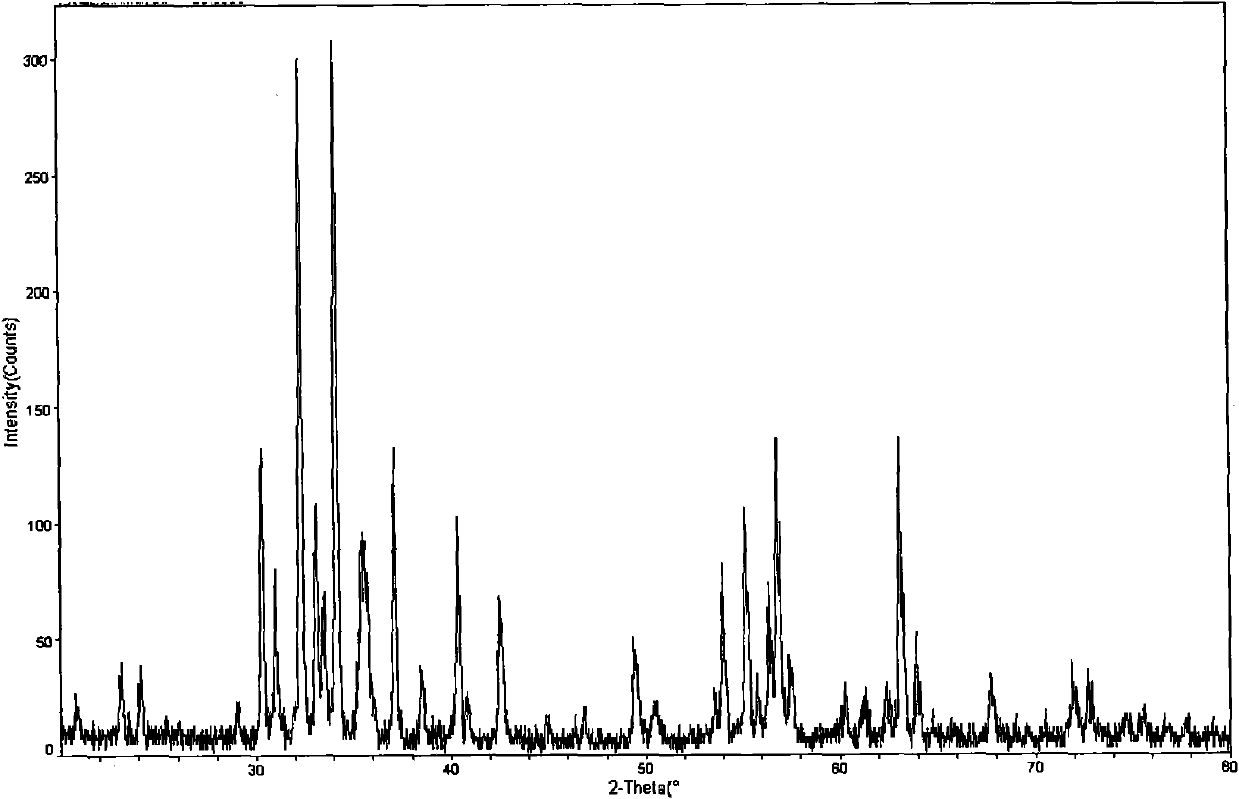

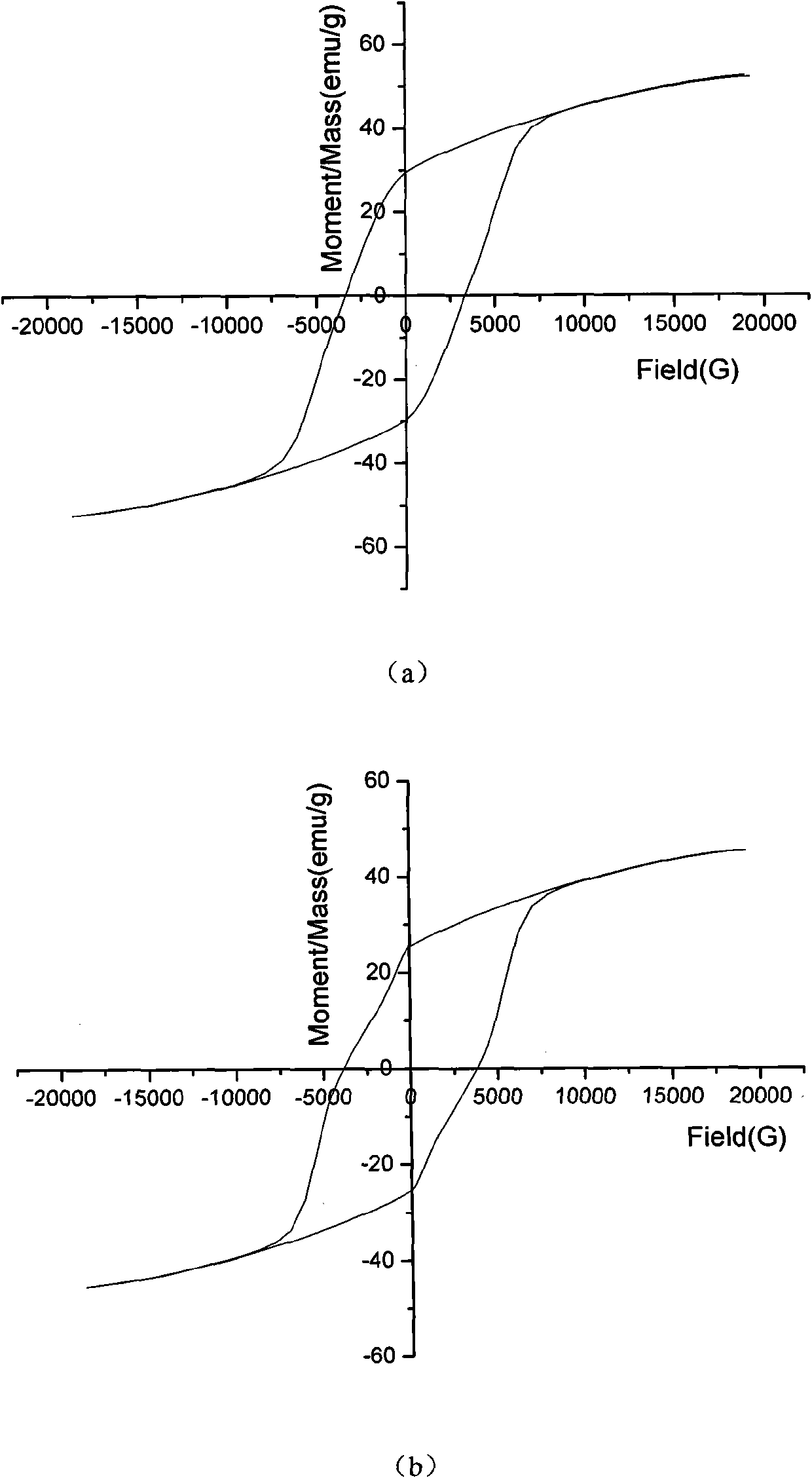

Image

Examples

Embodiment 1

[0028] A method for preparing strontium magnetic solid superacid catalyst by dipping and roasting, the specific steps are as follows:

[0029] (1) extract strontium carbonate

[0030] Using strontium slag as raw material, the strontium slag is pulverized by a pulverizer first, and then sieved with a sieve with an aperture of 0.074mm, and the strontium slag on the sieve and the sieved strontium slag powder are collected respectively. The strontium slag on the sieve is returned to pulverization and sieving; to the strontium slag powder sieved, the mass (g) of the strontium slag powder: molar concentration is 2.6mol / L and the volume (mL) ratio of the hydrochloric acid leaching agent is 1 : ratio of 7, put strontium slag powder and hydrochloric acid leaching agent into the reaction vessel, then heat with 98°C water bath, and stir and dissolve with a stirrer for 40min, stop heating and stirring, cool to room temperature, and filter for the first time with a filter , respectively c...

Embodiment 2

[0038] A method for preparing strontium magnetic solid superacid catalyst by dipping and roasting, the specific steps are as follows:

[0039] In the 1st (1) step: the molar concentration of hydrochloric acid is 2.5mol / L, the mass (g) of strontium slag powder: the volume (mL) ratio of hydrochloric acid leaching agent is 1: 6, and the temperature of water bath is 95 ℃, stirs The dissolving time is 35min, and the pH value of the filtrate collected by filtering for the first time is adjusted with sodium hydroxide solution to be 11.98, and the volume of adding sodium carbonate solution is 4 times of the filtrate collected by the second filtration, the reaction time is 15min, and the drying temperature is 100°C.

[0040] In (2) step: the mass (g) of strontium carbonate powder: the volume (mL) ratio of hydrochloric acid solution is 1: 6.4, and the mol ratio of strontium and iron is 1: 12.2, the mass (g) of ferric chloride hexahydrate : The volume (mL) ratio of distilled water is 1:...

Embodiment 3

[0045] A method for preparing strontium magnetic solid superacid catalyst by dipping and roasting, the specific steps are as follows:

[0046] In the 1st (1) step: the molar concentration of hydrochloric acid is 2.7mol / L, the quality (g) of strontium slag powder: the volume (mL) ratio of hydrochloric acid leaching agent is 1: 8., the temperature of water bath is 100 ℃, The stirring and dissolving time is 45min, and the pH value of the filtrate collected by the first filtration is adjusted with sodium hydroxide solution to be 12.15, and the volume of the sodium carbonate solution added is 6 times that of the filtrate collected by the second filtration, and the reaction time is 25min. It is 110°C.

[0047] In (2) step: the mass (g) of strontium carbonate powder: the volume (mL) ratio of hydrochloric acid solution is 1: 6.6, and the mol ratio of strontium and iron is 1: 12.6, and the mass (g) of ferric chloride hexahydrate : The volume (mL) ratio of distilled water is 1: 2.6, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com