Method for continuously preparing sucrose-6-acetic ester

A technology for acetate and sucrose, applied in the field of preparing sucrose-6-acetate, can solve problems such as low utilization rate of equipment, and achieve the effects of high utilization rate of equipment, improved utilization rate of equipment, and saving of intermediate operation time and process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

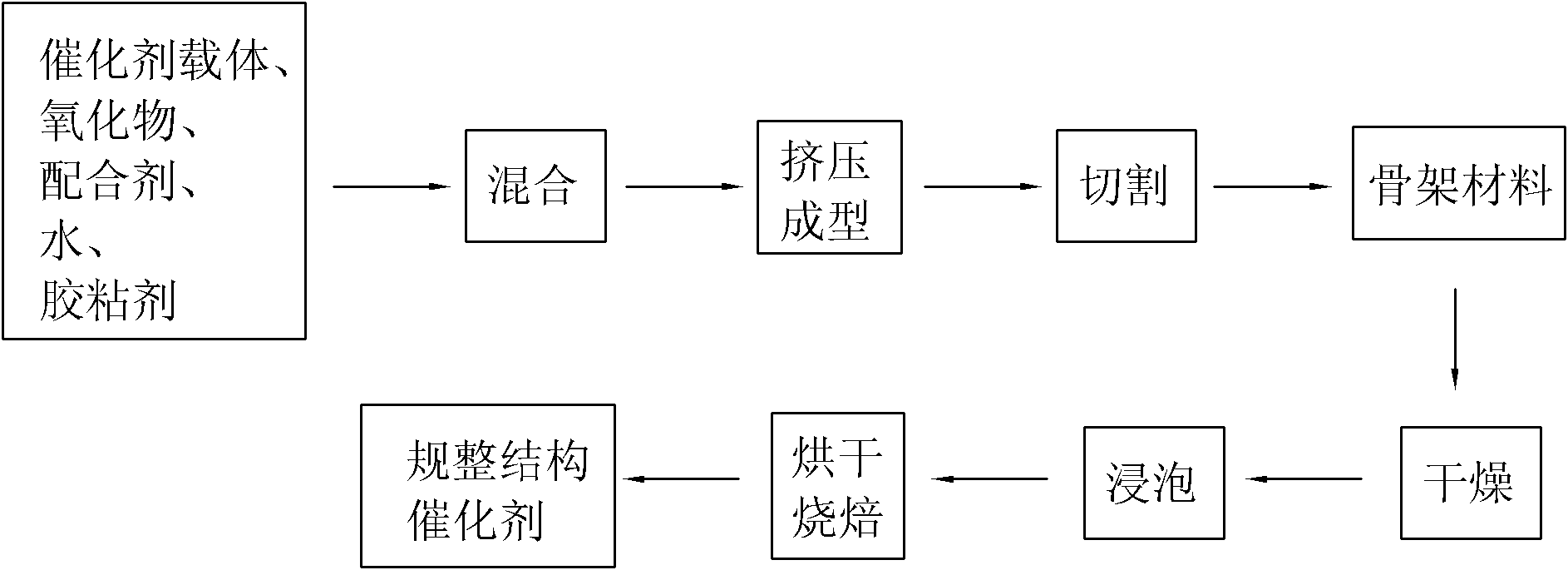

[0032] Preparation of a regular structure catalyst (see figure 1 ), mix the catalyst carrier, oxide, compounding agent, water and adhesive in parts by weight of 60: 20: 2: 15: 3 to form a certain plasticity mud:

[0033] The catalyst carrier is a mixture of one or more of diatomaceous earth, carboxymethyl cellulose, colloidal alumina and silica gel, preferably a mixture of one or two of diatomaceous earth and silica gel.

[0034] The oxide is TiO 2 , ZrO 2 , Fe 2 o 3 and Al 2 o 3 One or a mixture of several substances, preferably TiO 2 and Al 2 o 3 one or a mixture of both.

[0035] The compounding agent is a mixture of one or more substances in magnesium stearate, graphite, paraffin wax, talcum powder and EDTA, preferably one or two mixtures of magnesium stearate and graphite.

[0036] The adhesive is one or a mixture of polyvinyl alcohol, starch and water glass; preferably one or two mixtures of polyvinyl alcohol and water glass.

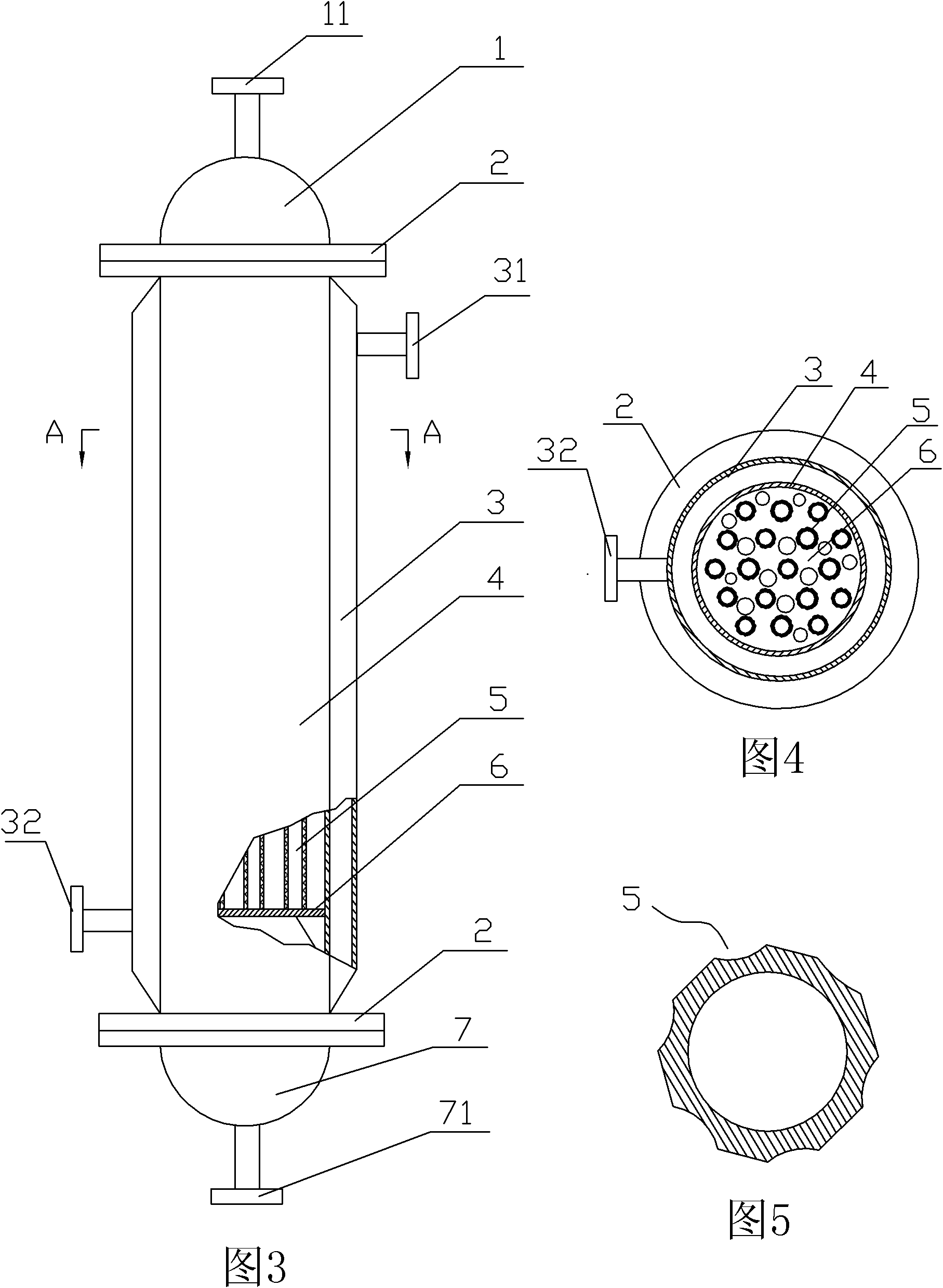

[0037] A hollow dodecagonal temp...

Embodiment 2

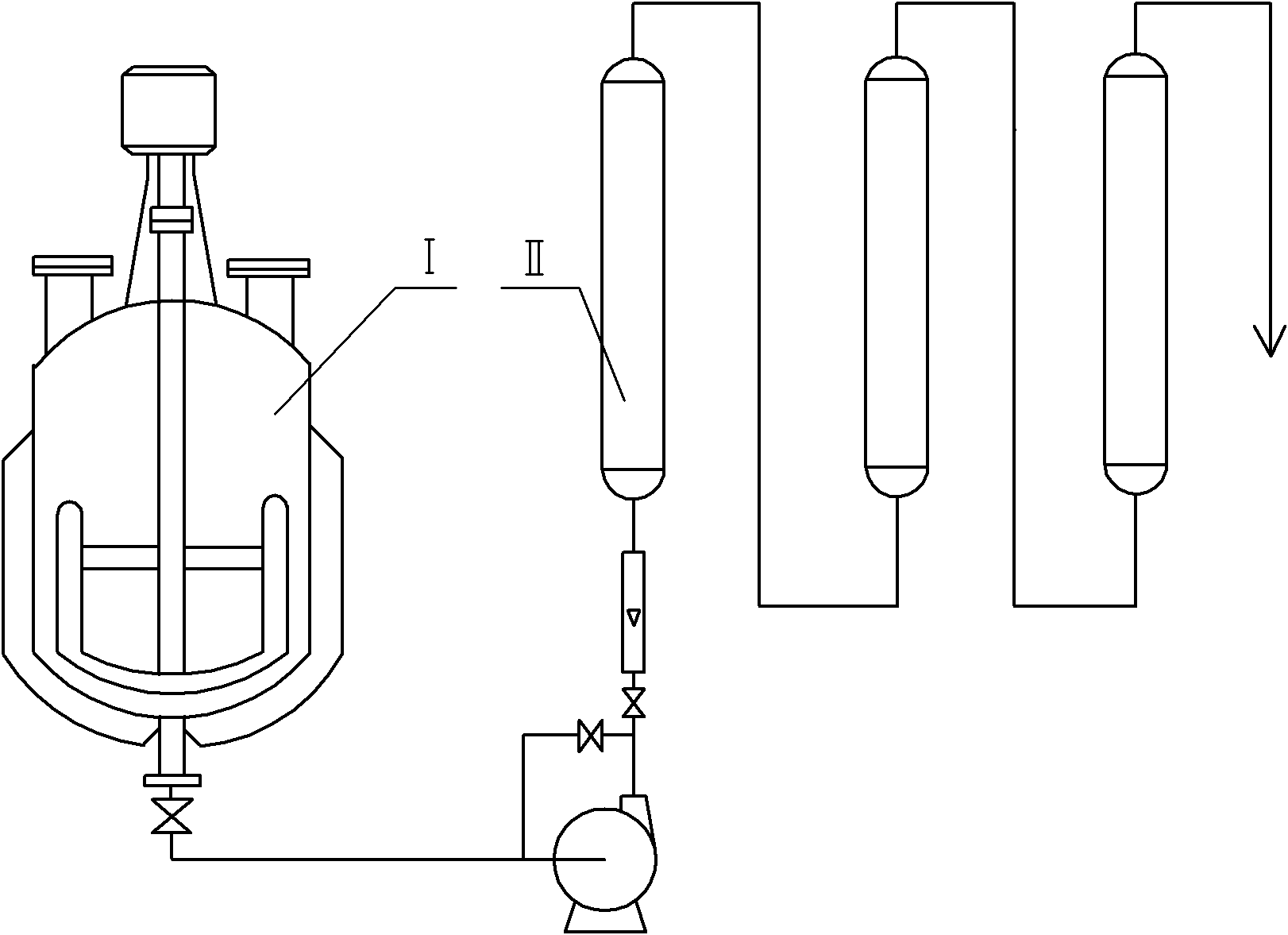

[0042] A kind of preparation of sucrose-6-acetate (see figure 2 ), add 10kg of sucrose, 35L of N,N-dimethylformamide (DMF), and 15L of ethyl acetate into the batching tank, heat up and stir evenly, and control the temperature at 80°C. Use a metering pump to continuously pump into the regular structure reactor at a flow rate of 16L / h. The total volume of the reactor is 32L, and the material flow rate per unit time and unit area is 8L / h·M 2 The calculated total surface area of the catalyst is about 2M 2 , The residence time of the material in the reactor is about 2.0h, and the outlet sampling analysis shows that the yield of sucrose-6-acetate is 69.6%.

Embodiment 3

[0044] A kind of preparation of sucrose-6-acetate (see figure 2 ), add 10kg of sucrose, 35L of DMF, and 15L of ethyl acetate into the batching tank, heat up and stir evenly, and control the temperature at 80°C. Use a metering pump to continuously pour into the structured structure reactor at a flow rate of 13L / h. The total volume of the reactor is 32L, and the material flow rate per unit time and unit area is 6.5L / h·M 2 The calculated total surface area of the catalyst is about 2M 2 , The residence time of the material in the reactor is about 2.5h, and the outlet sampling analysis shows that the yield of sucrose-6-acetate is 77.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com