Method for packaging LED (light emitting diode)

A technology of LED packaging and LED chips, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems that the improvement of LED light output efficiency is not very obvious or lower, and achieve the effect of improving light output efficiency and uniform aperture size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: In-line packaging of small die GaN-based blue LED with AAO film attached to the inner surface of the mold

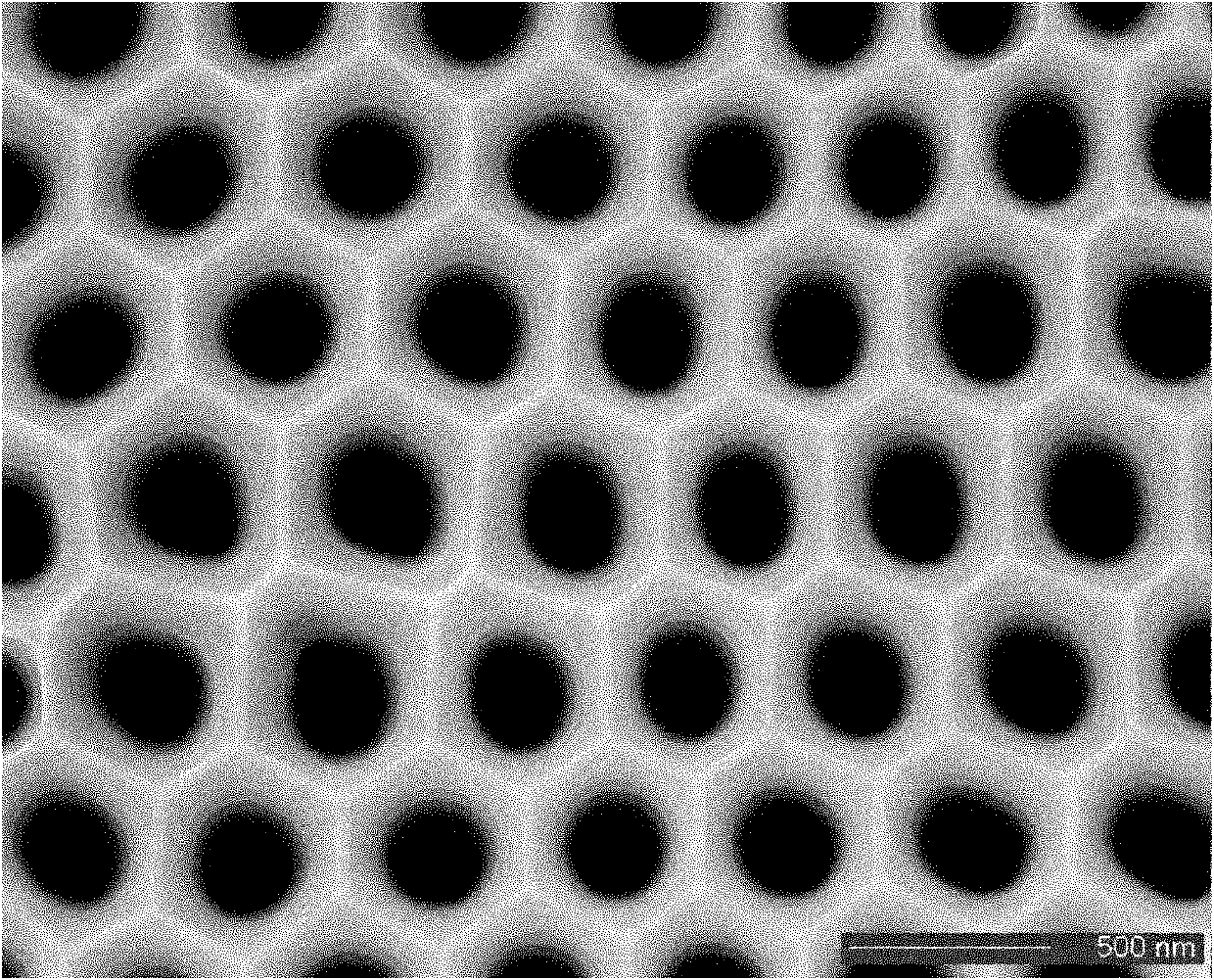

[0021] 1. Put the electropolished aluminum foil into a phosphoric acid solution, and prepare a periodic microstructure AAO film with a hole spacing close to 460nm (the emission wavelength of the blue LED tube core) by secondary anodic oxidation. Remove the aluminum substrate with a saturated copper chloride solution, and then expand the pores with a 5% phosphoric acid solution to obtain a periodic microstructured AAO template with a pore diameter of about 270 nm, such as figure 1 .

[0022] 2. Spread the AAO film with periodic microstructure prepared in step 1 evenly on the inner surface of the packaging mold.

[0023] 3. Inject liquid epoxy resin into the mold, and then insert the pressure-welded LED bracket into the silicon mold. The small die GaN-based blue LED has a light emission wavelength of about 460nm, such as figure 2 shown. Then it is bak...

Embodiment 2

[0024] Example 2: Encapsulating a small die GaN-based blue LED with a silicon mold prepared by an AAO template

[0025] 1. Put the electropolished aluminum foil into phosphoric acid solution, and prepare a periodic microstructure AAO film with a pore spacing of about 460 nm by secondary anodic oxidation. Remove the aluminum substrate with a saturated copper chloride solution, and then expand the pores with a 5% phosphoric acid solution to obtain a periodic microstructured AAO template with a pore diameter of about 270 nm, such as figure 1 .

[0026] 2. Spread the AAO film with periodic microstructure prepared in step 1 evenly on the inner surface of the silicon mold.

[0027] 3. Use the AAO template as a mask, etch the silicon mold with dry etching technology, and then remove the AAO template to obtain a reusable silicon packaging mold with a periodic microstructure on the inner surface.

[0028] 4. Spray the release agent on the inner surface of the silicon mold, then injec...

Embodiment 3

[0029] Embodiment 3: High-power vertical structure GaN-based blue LED chip packaging

[0030] 1. Put the electropolished aluminum foil into phosphoric acid solution, and prepare a periodic microstructure AAO film with a pore spacing of about 460 nm by secondary anodic oxidation. Remove the aluminum substrate with a saturated copper chloride solution, and then expand the pores with a 5% phosphoric acid solution to obtain a periodic microstructure through-hole AAO template with a pore diameter of about 270 nm, such as figure 1 .

[0031] 2. Spread the AAO film with a periodic microstructure prepared in step 1 evenly on the surface of the high-power vertical structure LED die n-GaN, and then use inductively coupled plasma (ICP) etching, the etching of n-GaN The depth is about 1um. After the etching is completed, the AAO template on the surface of the die is removed to obtain an n-GaN light-emitting surface with a periodic microstructure.

[0032] 3. Fix the high-power vertical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com