Method for treating high-calcium and high-salt industrial wastewater

A technology of industrial wastewater and treatment methods, applied in the field of water treatment, can solve the problems of undisclosed saline wastewater treatment, etc., and achieve the effect of weakening the tendency of wastewater scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

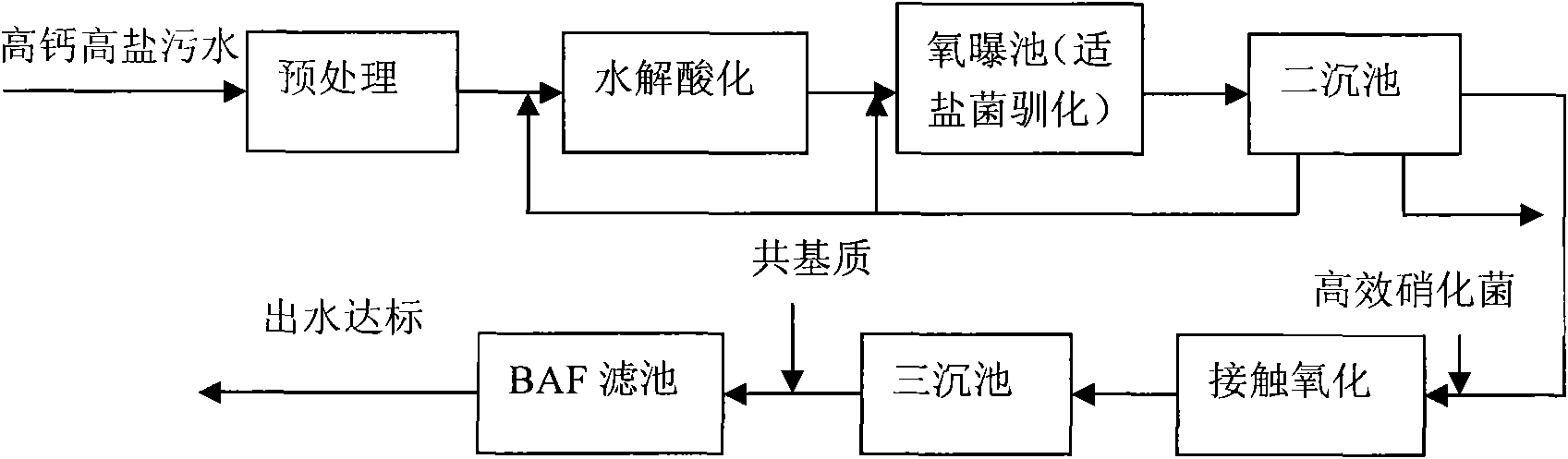

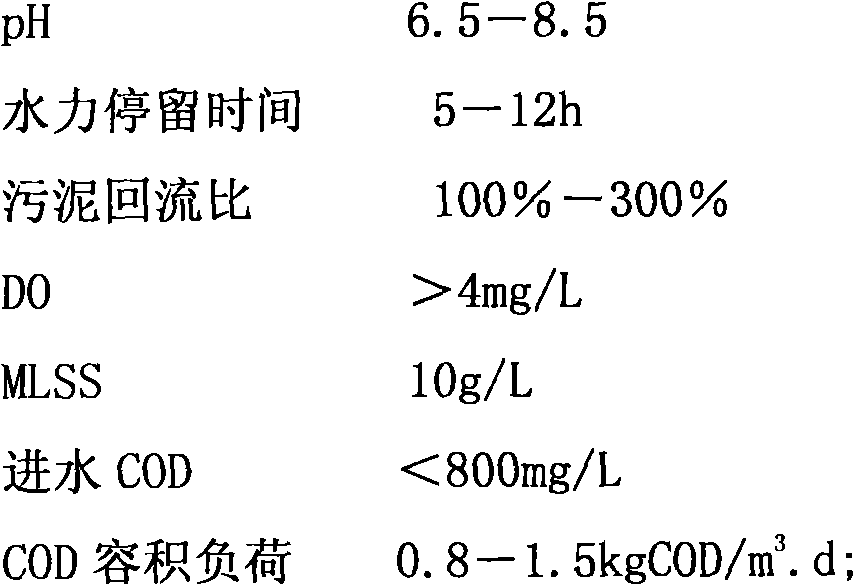

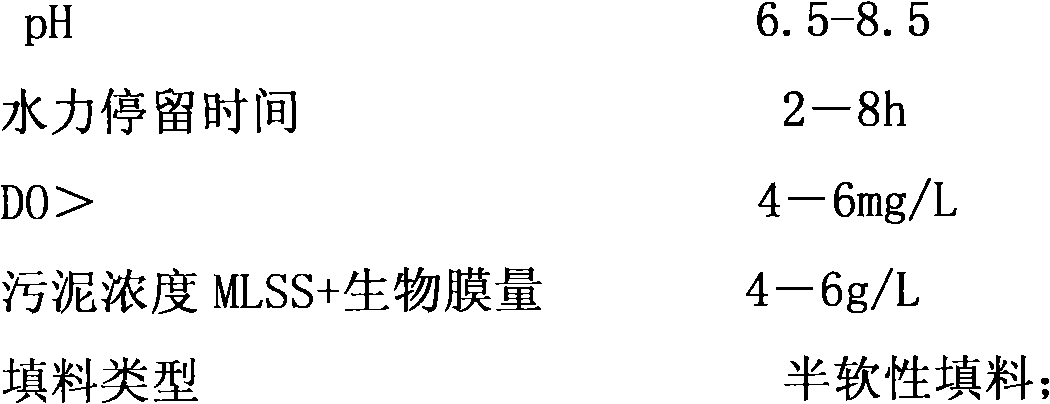

Method used

Image

Examples

Embodiment 1

[0098] Salinity content (TDS) 3.0%, COD1250mg / L, NH 3 -The industrial waste water of N 37.6mg / L enters the high-calcium, high-salinity industrial waste water treatment system of the present invention;

[0099] a. Pretreatment system,

[0100] ①Mixed flocculation and settling unit: adding flocculant, the reaction time is 10 minutes, and the settling time is 60 minutes;

[0101] ② Pre-oxidation unit: use compressed air to aerate, control the dissolved oxygen between 1.0-2.0mg / L; adjust the pH and control the pH value between 6.0-6.5; built-in iron shavings, its porosity is 55%-95% ;

[0102] b. The hydrolytic acidification tank of the hydrolytic acidification anaerobic biochemical treatment system is divided into two sections I and II, and the structural characteristics are as follows:

[0103] ① Section I pool occupies about 3 / 5 of the volume of the pool, and adopts an intensity-controllable submerged agitator;

[0104] ②The second-stage pool accounts for about 2 / 5 of the v...

Embodiment 2

[0127] According to the method and step of embodiment 1, process index is as follows:

[0128] The salinity content (TDS) of industrial wastewater entering the system is 2.0%, COD1126mg / L, NH 3 -N41.3mg / L,

[0129] a. Pretreatment system,

[0130] ①Mixed flocculation and settling unit: adding flocculant, the reaction time is 10 minutes, and the settling time is 120 minutes;

[0131] ② Pre-oxidation unit: use compressed air to aerate, control the dissolved oxygen between 1.0-2.0mg / L; adjust the pH and control the pH value between 6.0-6.5; built-in iron shavings, its porosity is 55%-95% ;

[0132] b. The hydrolytic acidification tank of the hydrolytic acidification anaerobic biochemical treatment system is divided into two sections I and II, and the structural characteristics are as follows:

[0133] ① Section I pool occupies about 3 / 5 of the volume of the pool, and adopts an intensity-controllable submerged agitator;

[0134] ②The second-stage pool accounts for about 2 / 5 o...

Embodiment 3

[0157] According to the method and step of embodiment 1, process index is as follows:

[0158] The salinity content (TDS) of industrial wastewater entering the system is 1.51%, COD881.0mg / L, NH 3 -N11.7mg / L,

[0159] a. Pretreatment system,

[0160] ①Mixed flocculation and settling unit: adding flocculant, the reaction time is 10 minutes, and the settling time is 120 minutes;

[0161] ② Pre-oxidation unit: use compressed air to aerate, control the dissolved oxygen between 1.0-2.0mg / L; adjust the pH and control the pH value between 6.0-6.5; built-in iron shavings, its porosity is 55%-95% ;

[0162] b. The hydrolytic acidification tank of the hydrolytic acidification anaerobic biochemical treatment system is divided into two sections I and II, and the structural characteristics are as follows:

[0163] ① Section I pool occupies about 3 / 5 of the volume of the pool, and adopts an intensity-controllable submerged agitator;

[0164] ②The second-stage pool accounts for about 2 / 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com