Heat conducting composite material and injection molding process for combining same and LED metal shell

A heat-conducting composite material and LED housing technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problem of small plasticity and diversity of appearance, unsafe and reliable use, affecting LED luminous efficiency and luminous flux maintenance High thermal conductivity, thermophysical and mechanical properties, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] A heat-conducting composite material, which includes the following raw materials in parts by weight: 46 parts of polyhexamethylene adipamide, 5 parts of graphite, 2 parts of molybdenum disulfide, 0.5 part of nano-calcium carbonate, 2 parts of glass fiber, and 0.5 part of coupling agent , 1 part of antioxidant, 0.5 part of processing aid.

[0068] An injection molding process for combining the above-mentioned heat-conducting composite material with the LED metal casing, which includes the following process steps.

[0069] (a) Drying and granulation of raw materials: take raw materials according to the above parts by weight, dry polyhexamethylene adipamide in a plastic hopper dryer at 100°C for 6 hours; Put glass fiber, coupling agent, antioxidant, and processing aid into an ordinary dryer at 60°C to dry for more than 2 hours, and then extrude the dried raw materials to granulate. The extrusion granulation temperature is 240°C, and the vacuum degree is less than 0.06Mpa....

Embodiment 2

[0075] A heat-conducting composite material, which includes the following raw materials in parts by weight: 73 parts of polyhexamethylene adipamide, 15 parts of graphite, 10 parts of molybdenum disulfide, 2 parts of nano-calcium carbonate, 10 parts of glass fiber, and 3 parts of coupling agent , 1.5 parts of antioxidant, 1.5 parts of processing aid.

[0076] An injection molding process for combining the above-mentioned heat-conducting composite material with the LED metal casing, which includes the following process steps.

[0077] (a) Drying and granulation of raw materials: take the raw materials according to the above parts by weight, and dry polyhexamethylene adipamide in a plastic hopper dryer at 110°C for 6 hours; Put glass fiber, coupling agent, antioxidant, and processing aid into an ordinary dryer at 65°C to dry for more than 2 hours, and then extrude the dried raw materials to granulate. The extrusion granulation temperature is 250°C, and the vacuum degree is 0.02M...

Embodiment 3

[0083] A heat-conducting composite material, which includes the following raw materials in parts by weight: 82 parts of polyhexamethylene adipamide, 25 parts of graphite, 8 parts of molybdenum disulfide, 1 part of nano-calcium carbonate, 15 parts of glass fiber, and 5 parts of coupling agent , 2 parts of antioxidant, 2 parts of processing aid.

[0084] An injection molding process for combining the above-mentioned heat-conducting composite material with the LED metal casing, which includes the following process steps.

[0085] (a) Drying and granulation of raw materials: take raw materials according to the above parts by weight, and dry polyhexamethylene adipamide for 6 hours in a plastic hopper dryer at 115° C.; Put glass fiber, coupling agent, antioxidant, and processing aid into an ordinary dryer at 75°C to dry for more than 2 hours, and then extrude the dried raw materials to granulate. The extrusion granulation temperature is 260°C, and the vacuum degree is 0.04Mpa.

[...

PUM

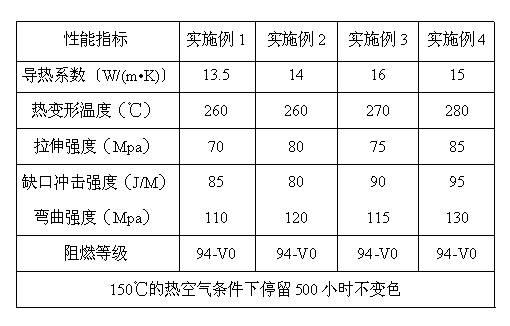

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com