Antiphagin L-phenylalanine producing strain as well as breeding method and application thereof

A phenylalanine, anti-phage technology, applied in the field of bioengineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 Isolation and purification of recombinant Escherichia coli WSH-Z06 (pAP-B03) susceptible phage BP-1

[0034] The source of the strain: the L-phenylalanine-producing strain recombinant Escherichia coli WSH-Z06 (pAP-B03) developed by our laboratory earlier, the strain preservation number is CCTCC M 2010009, which has been preserved in the China Center for Type Culture Collection. Date: January 14, 2010, Address: Wuhan University, Wuhan, China, taxonomic name: Escherichia coli ( Escherichia coli ).

[0035] Take 4mL of recombinant Escherichia coli WSH-Z06 (pAP-B03) fermentation broth infected by phage in a factory, centrifuge at 8000rpm for 10min, filter the supernatant through a 0.22μm microporous membrane, take out 100μL and put 6mL of the upper layer at 50℃ Add 100 μL of WSH-Z06 (pAP-B03) (CCTCC M2010009) bacterial suspension to the test tube of meat extract peptone medium at the same time, mix immediately, pour on the solidified bottom medium, spread evenly...

Embodiment 2

[0037] The breeding of embodiment 2 anti-phage Escherichia coli

[0038] A. Starting strain

[0039] The host strain WSH-Z06 of the recombinant Escherichia coli that has been industrialized for the production of L-phenylalanine.

[0040] Escherichia coli (Escherichia coli) WSH-Z06 (pAP-B03) (CCTCC M 2010009) is the starting strain for the selection of anti-phage recombinant bacteria in this laboratory.

[0041] B. Phage

[0042] The phage is BP-1, which was isolated through Example 1.

[0043] C. Medium

[0044] Seed medium: LB medium (peptone 10g / L, yeast powder 5g / L, NaCl 10g / L); if the cells contain plasmid, add kanamycin sulfate 40μg / mL, pH 7.3, add 2% to the solid medium of agar.

[0045] Phage resistance detection medium: meat extract peptone medium (beef extract 5g / L, peptone 10g / L, glucose 10g / L, NaCl 5g / L), pH 7.0-7.2, agar 2%.

[0046] D. Mutagenesis and isolation screening of mutant strains

[0047] Put a ring of WSH-Z06 from a fresh slant into LB medium (25m...

Embodiment 3

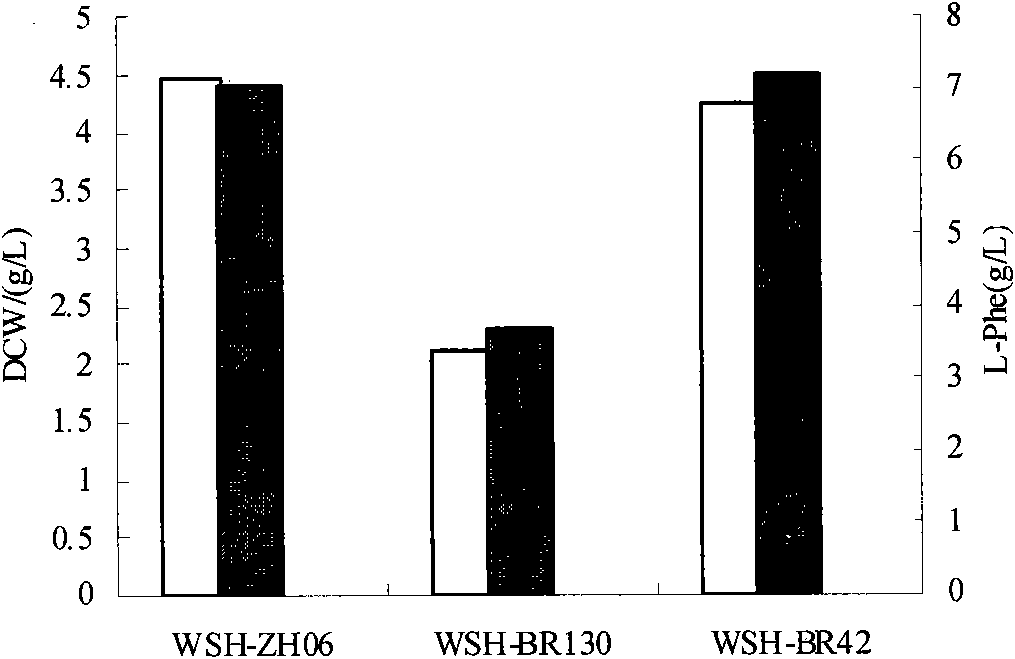

[0050] Embodiment 3 Plasmid pAP-B03 transforms WSH-BR42 and WSH-BR130

[0051] Competent cells of Escherichia coli WSH-Z06 mutant strains WSH-B42 and WSH-BR130 were prepared by the method provided by the efficient preparation of competent cell kit (Shanghai Sangong). The prepared competent cells were placed on ice, and the plasmid pAP-B03 (constructed earlier, Enhanced L-phenylalanine biosynthesis by co-expression of pheA) was added to each tube (110 μL). fbr and aroF wt ) 2 μL, swirl gently to mix the contents, place on ice for 30 minutes, then place in a water bath at 42°C for 90 seconds, then quickly transfer to an ice bath to cool the cells for 1-2 minutes. Add 600 μL of liquid seed medium to each tube, and bathe in water at 37°C for 2 hours. Pipette 50 μL of transformed competent cells onto LB plates containing kanamycin sulfate, spread evenly, and culture overnight in a 37°C incubator. When a single colony grows, it is placed on an LB slant containing kanamycin sulfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com