Preparation method of liquid inoculant of aboriginal probiotic bacillus megaterium, bacillus mucilaginosus and azotobacter chroococcum

A technology for Bacillus megaterium and jelly-like spores, which is applied in the field of preparation of liquid inoculants, can solve problems such as inability to save energy, complex production processes, application limitations, etc., and achieves reduction of processes and production processes for raw material preparation and autoclaving Simple, labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: a kind of indigenous probiotic bacillus megaterium, jelly-like bacillus and torus brown nitrogen-fixing bacteria liquid inoculum, by bacillus megaterium (Bacillus megaterium), jelly-like bacillus (Bacillus mucilaginosus), jelly-like azotobacter ( Azotobacter chroococcum) and liquid culture medium, the percentage by weight of its three bacterial strains is 55-65% for Bacillus megaterium, 30-35% for Bacillus jelly-like, and 5-10% for Azotobacter rotundum. The preservation number of the bacillus is CGMCC No.3770; the preservation number of the jelly-like bacillus is CGMCC No.3769;

[0027] The liquid medium includes adding 1-2 g of ammonium sulfate and 0.5-1 ml of phosphoric acid to 1 liter of fresh tofu wastewater or vermicelli wastewater or corn starch wastewater or potato starch wastewater, and adjusting the pH to 7.2-7.5 with 1% lime water.

Embodiment 2

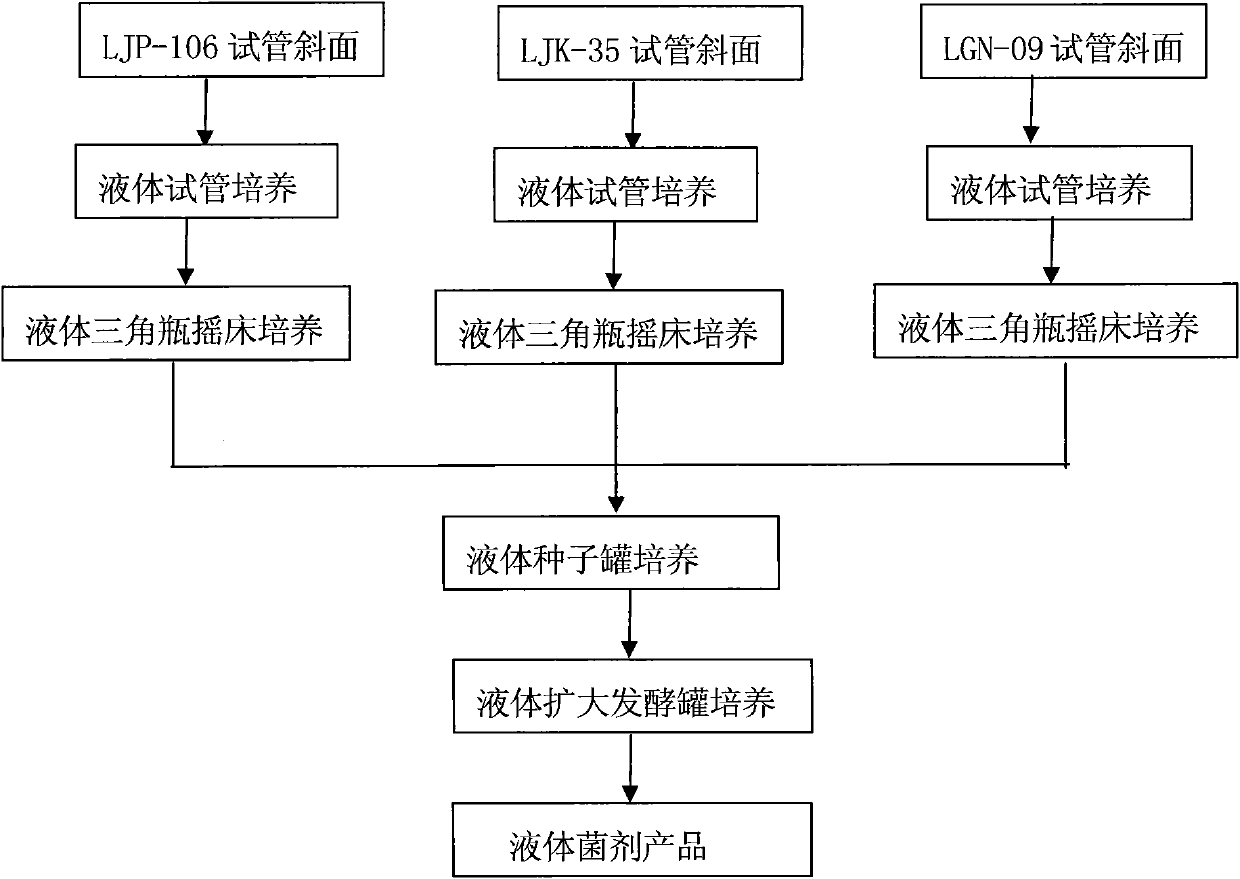

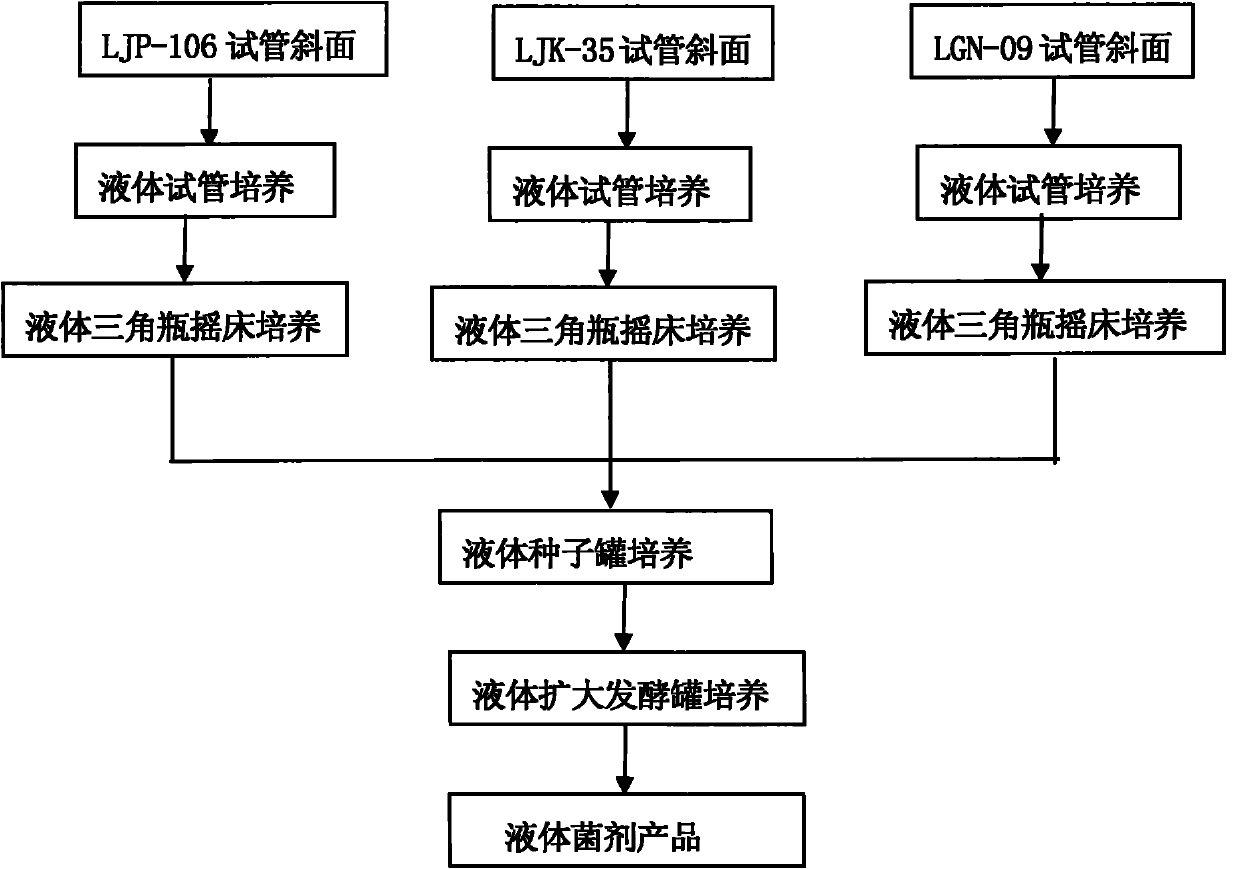

[0028] Example 2: see figure 1 , a preparation method of indigenous probiotic Bacillus megaterium, Bacillus jelly-like and Azotobacter torusus liquid inoculum, which has the following steps:

[0029]A. Preparation of indigenous probiotic Bacillus megaterium and Bacillus jelly-like agar slant medium and cultivation of strains:

[0030] a. Preparation of agar slant medium: 0.5-2% wort juice, 0.5-2% glucose, 0.2-0.6% peptone, 1-3% agar powder, 80-120ml sterile water, after heating and dissolving, use 1% Adjust the pH value to 7.0-7.5 with sodium hydroxide, steam sterilize at 110-114°C for 30-35 minutes, and then subpackage under aseptic conditions into dry and sterilized test tubes of 15×1.5cm, set them on an inclined plane and wait for solidification. use;

[0031] b. Cultivation of indigenous probiotic Bacillus megaterium and Bacillus jelly-like strains: respectively take the mother species of Bacillus megaterium and Bacillus jelly-like on the agar slant, and transfer them t...

Embodiment 3

[0043] Embodiment 3: see figure 1 , a preparation method of indigenous probiotic Bacillus megaterium, Bacillus jelly-like and Azotobacter torusus liquid bacterial preparation, it has the following steps: Steps A-B are the same as in Example 2,

[0044] C Indigenous probiotics Bacillus megaterium, Bacillus jelly-like, Azotobacter rotundum liquid culture medium preparation and liquid bacteria:

[0045] (1) For the cultivation of test tube liquid strains, get 100ml of fresh vermicelli waste water, add (NH 4 ) 2 SO 4 0.1g, H 3 PO 4 0.05ml, after fully dissolving, adjust the pH to 7.0~7.5, divide into dry test tubes of 15×1.2cm, autoclave at 112°C for 30 minutes, cool to 32°C, inoculate Bacillus megaterium and jelly-like spores respectively Bacillus and Azotobacter rotundum are cultured in test tube liquid culture medium for 24 to 48 hours at 28 to 32°C to become test tube liquid strains (secondary strains).

[0046] (2) The cultivation of Erlenmeyer flask liquid strain:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com