Method and device for machining tungsten and titanium alloy target material

A technology of tungsten-titanium alloy and processing device, which is applied in the direction of metal processing equipment, metal material coating technology, grinding device, etc., can solve problems such as cracking of tungsten-titanium alloy target material, reduce cracking defects, reduce processing costs, reduce wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment provides a method for processing a tungsten-titanium alloy target, aiming to solve the problem that the existing processing method is prone to cracking defects in the tungsten-titanium alloy target through the improvement and control of the three elements of machining.

[0030] First of all, in mechanical processing, people usually want the shortest processing time, long processing device life and high processing accuracy. Therefore, the material and material, hardness, shape and condition of the workpiece must be fully considered before processing. The performance of the machine tool, and then select the appropriate processing tools and use high-efficiency processing conditions, wherein the processing conditions, in the field of mechanical processing technology, are the three elements of mechanical processing, including: rotational speed, feed rate and feed speed.

[0031] Speed: A unit of measurement for the rotational speed of a rotating object. It ref...

Embodiment 2

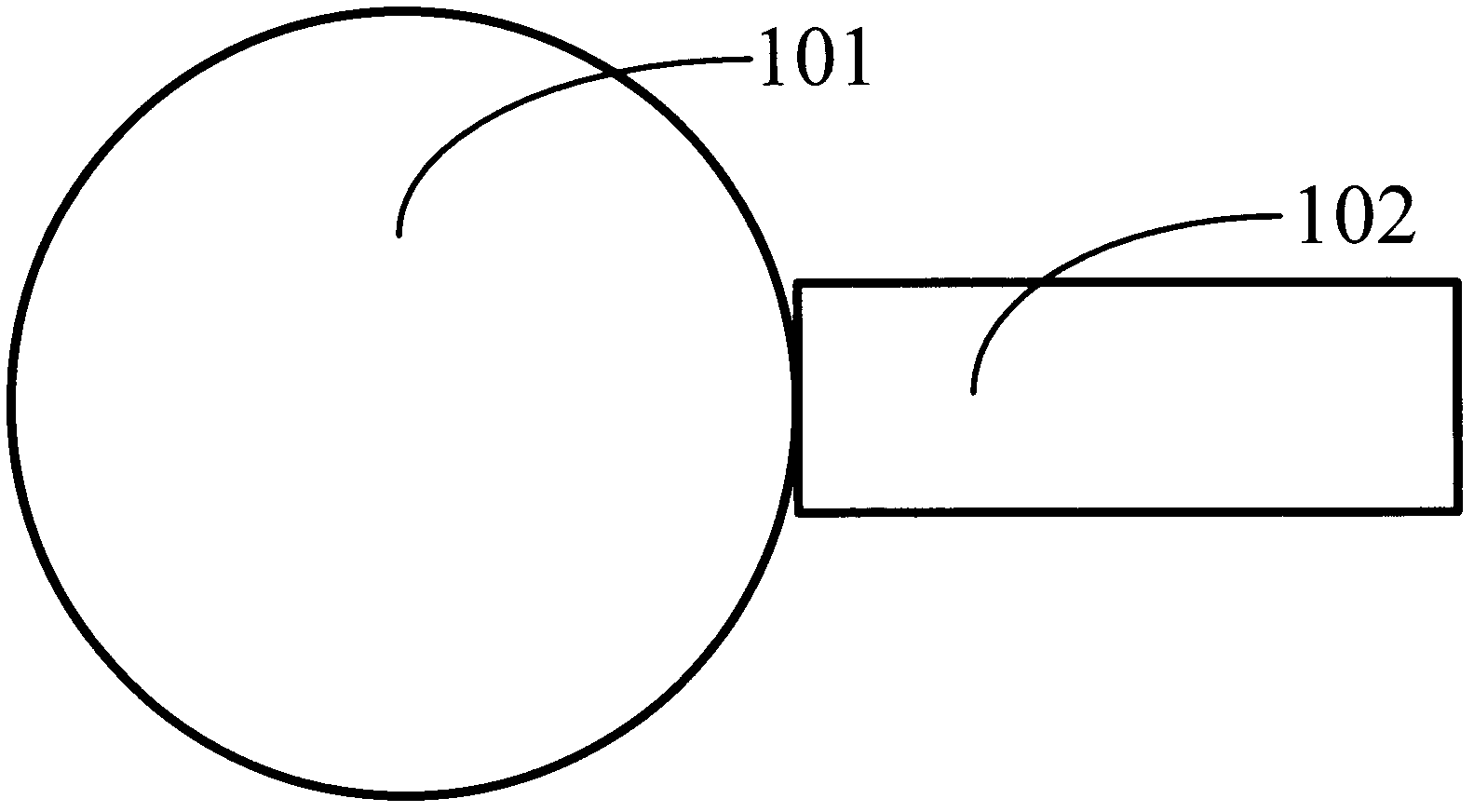

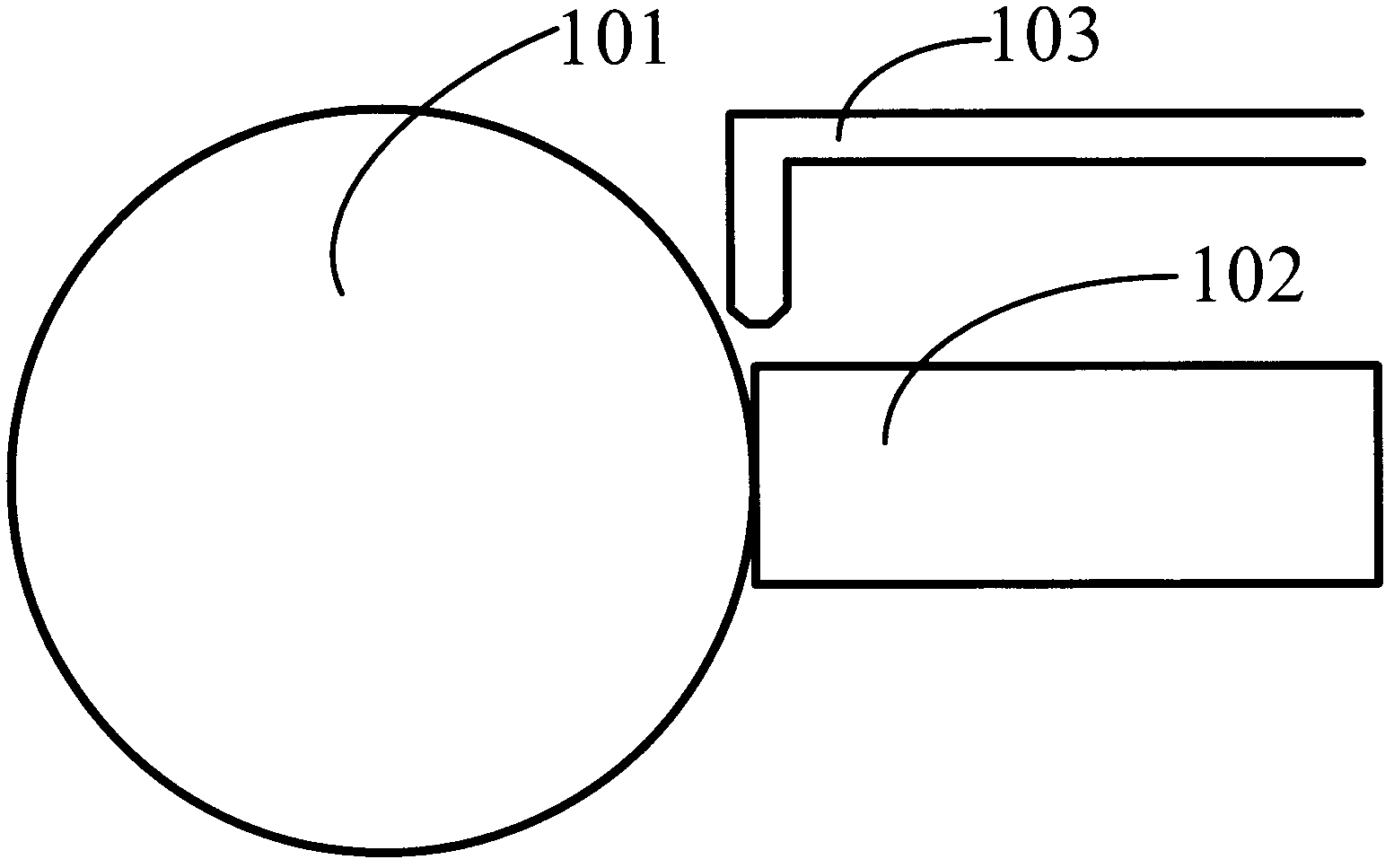

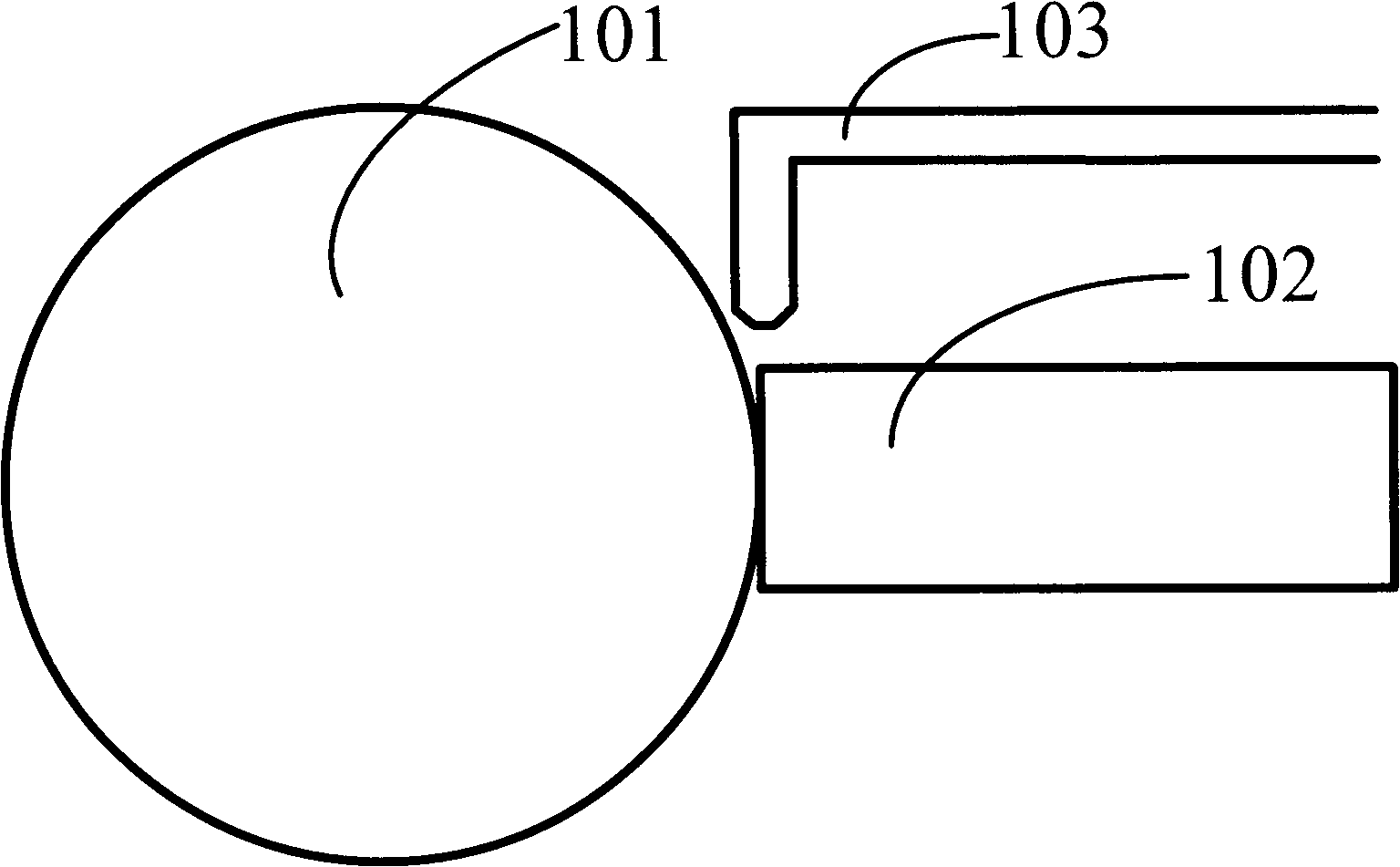

[0046]Due to the low hardness of the processing device of ordinary material used in the prior art, and the high hardness of the target made of tungsten-titanium alloy, when the tungsten-titanium alloy target is processed by the ordinary processing device, it is easy to cause the tungsten-titanium alloy target The cracking of the material will also cause serious wear of the processing device, requiring frequent replacement of the processing device, which will result in low processing efficiency and high processing cost.

[0047] For this reason, this embodiment provides a tungsten-titanium alloy target processing device, aiming at solving the problem that the existing processing device is prone to cracking defects of the tungsten-titanium alloy target by improving the material of the processing grinding device.

[0048] The material processed by the tungsten-titanium alloy target provided in this embodiment includes diamond with a particle size of 120 to 150 mesh.

[0049] Spec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com