Scopolamine transdermal patch and preparation method thereof

A technology of scopolamine and transdermal patch, applied in the field of scopolamine transdermal patch and its preparation, can solve the problems of long dissolution time, long onset time, potential safety hazards, etc. The effect of production volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

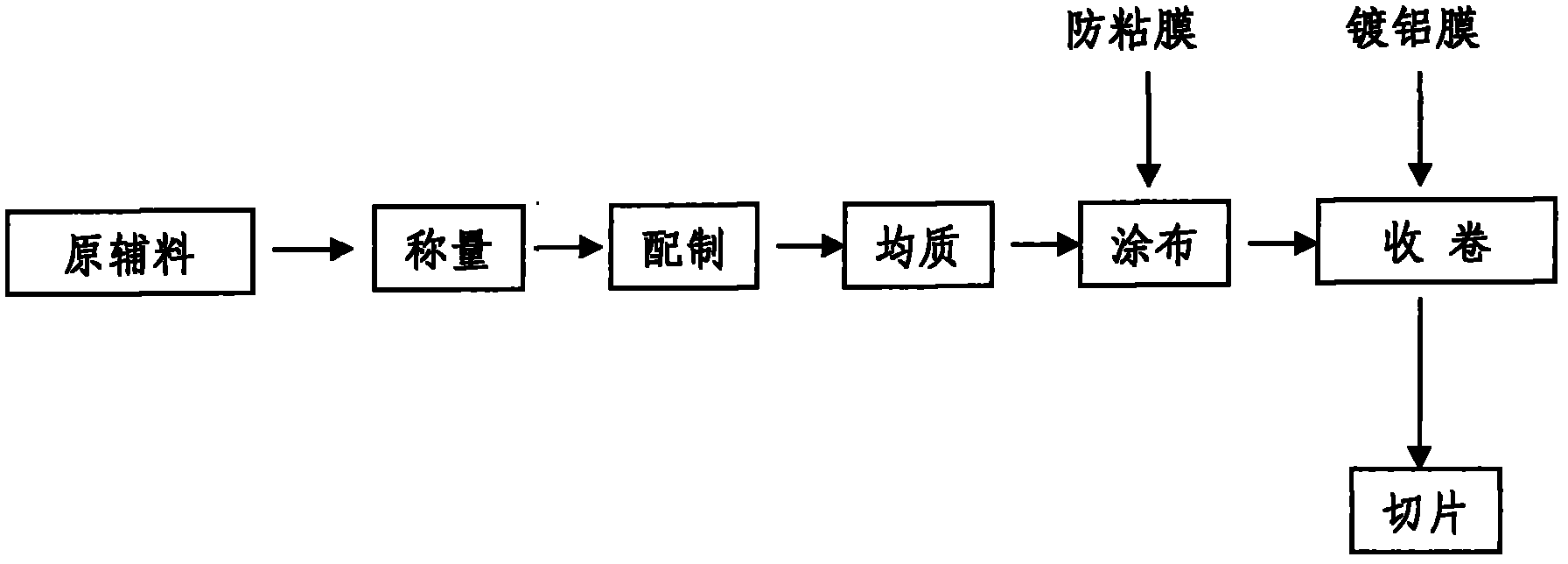

Method used

Image

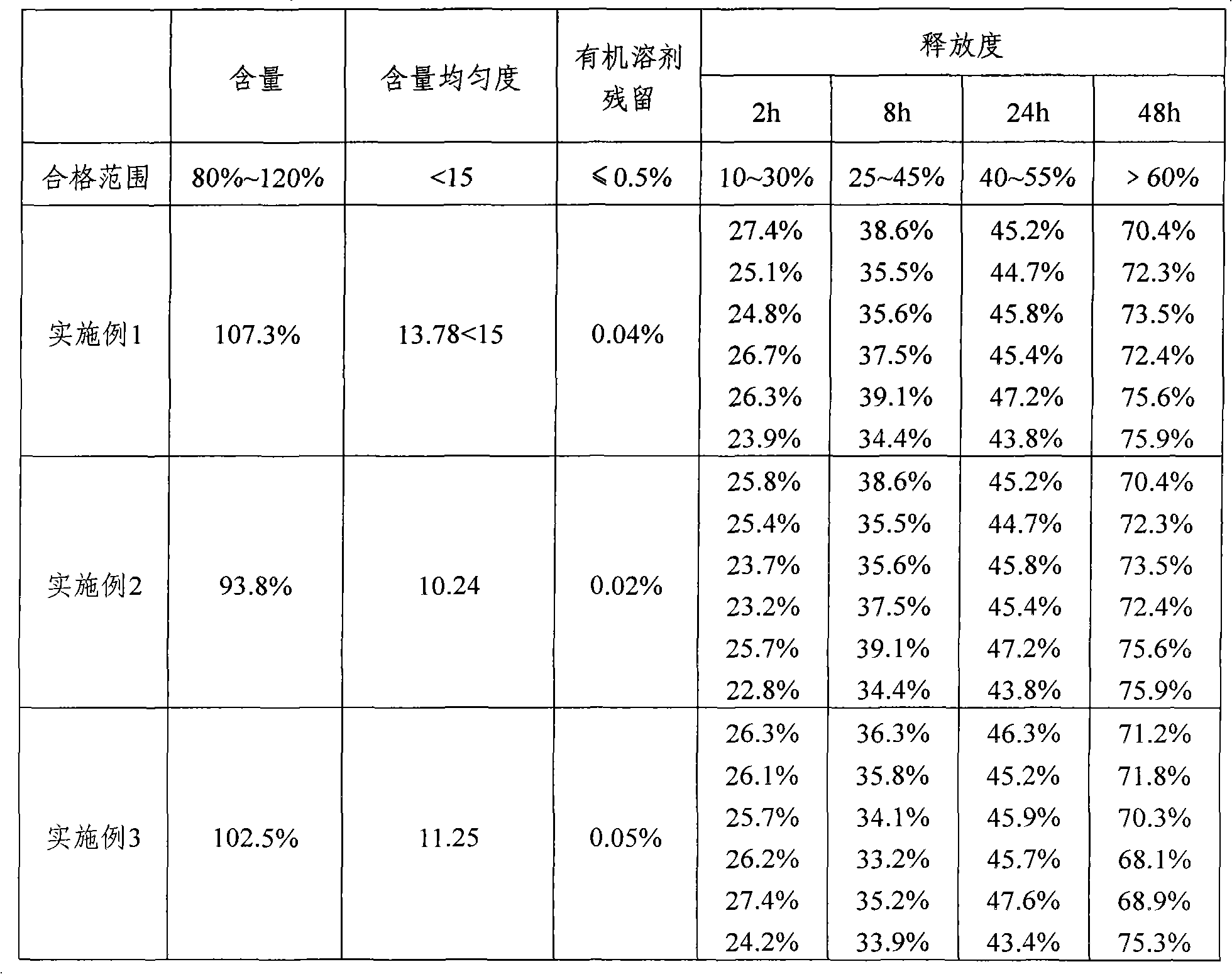

Examples

Embodiment 1

[0026] (1) Weigh 30g of absolute ethanol and add it to 70g of polyacrylic acid resin, stir and dissolve; then add in 290g of acrylic pressure-sensitive adhesive and stir evenly, set aside;

[0027] (2) Take by weighing 10g azone and 15g propylene glycol, dissolve with 20g cyclohexane, then add 15g pulverized scopolamine (crushed through a 100 mesh sieve), after stirring evenly, set aside;

[0028] (3) Add the solution obtained in step (2) to the solution obtained in step (1); rinse the container of step (2) with 5g cyclohexane and add it to the solution obtained in step (1), stir for 30min; The machine is homogenized 3 times under the pressure of 12Mpa;

[0029] (4) Dry and coat the above-mentioned homogenized solution on a release film coated with silicon polymer on one side with a coater to form a drug layer. The drying temperature of the coater is 35° C., and the thickness of the drug layer is 40 μm; Then clad with aluminized film;

Embodiment 2

[0032] (1) Weigh 40g of absolute ethanol and add it to 60g of polyacrylic acid resin, stir and dissolve; then add in 300g of acrylic pressure-sensitive adhesive and stir evenly, set aside;

[0033] (2) Take by weighing 15g azone and 20g propylene glycol, dissolve with 15g cyclohexane, then add 15g pulverized scopolamine (crushed through a 100 mesh sieve), stir evenly, and set aside;

[0034] (3) Add the solution obtained in step (2) to the solution obtained in step (1); rinse the container of step (2) with 5g cyclohexane and add it to the solution obtained in step (1), stir for 30min; The machine is homogenized 3 times under the pressure of 10Mpa;

[0035] (4) Dry and coat the above-mentioned homogenized solution on a release film coated with silicon polymer on one side with a coater to form a drug layer. The drying temperature of the coater is 45° C., and the thickness of the drug layer is 45 μm; Then clad with aluminized film;

Embodiment 3

[0038] (1) Weigh 50g of absolute ethanol and add it to 50g of polyacrylic acid resin, stir and dissolve; then add in 310g of acrylic pressure-sensitive adhesive and stir evenly, set aside;

[0039] (2) Take by weighing 20g azone and 25g propylene glycol, dissolve with 10g cyclohexane, then add 15g pulverized scopolamine (crushed through a 100 mesh sieve), stir evenly, and set aside;

[0040] (3) Add the solution obtained in step (2) to the solution obtained in step (1); rinse the container of step (2) with 5g cyclohexane and add it to the solution obtained in step (1), stir for 30min; The machine is homogenized 5 times under the pressure of 12Mpa;

[0041] (4) Dry and coat the above-mentioned homogenized solution on a release film coated with silicon polymer on one side with a coater to form a drug layer. The drying temperature of the coater is 55° C., and the thickness of the drug layer is 45 μm; Then clad with aluminized film;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com