Method for preparing liquid fuel from biomass through hydrogen-donor solvent

A liquid fuel and biomass raw material technology, applied in the preparation of liquid hydrocarbon mixtures, the petroleum industry, etc., can solve the problems of difficult processing, complex composition, high cost, etc., to simplify the cooling and condensation process, save equipment investment, and pressure requirements low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

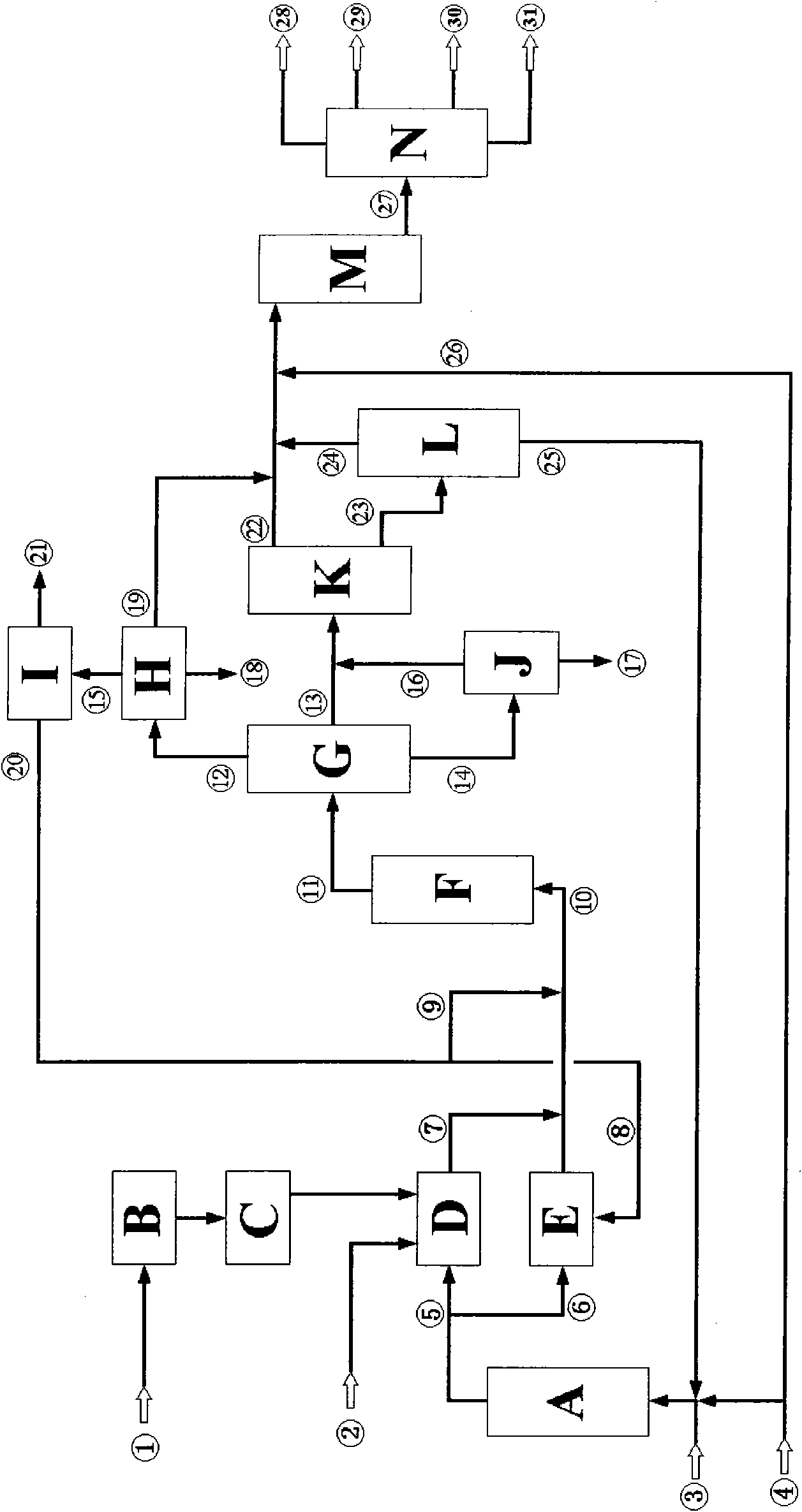

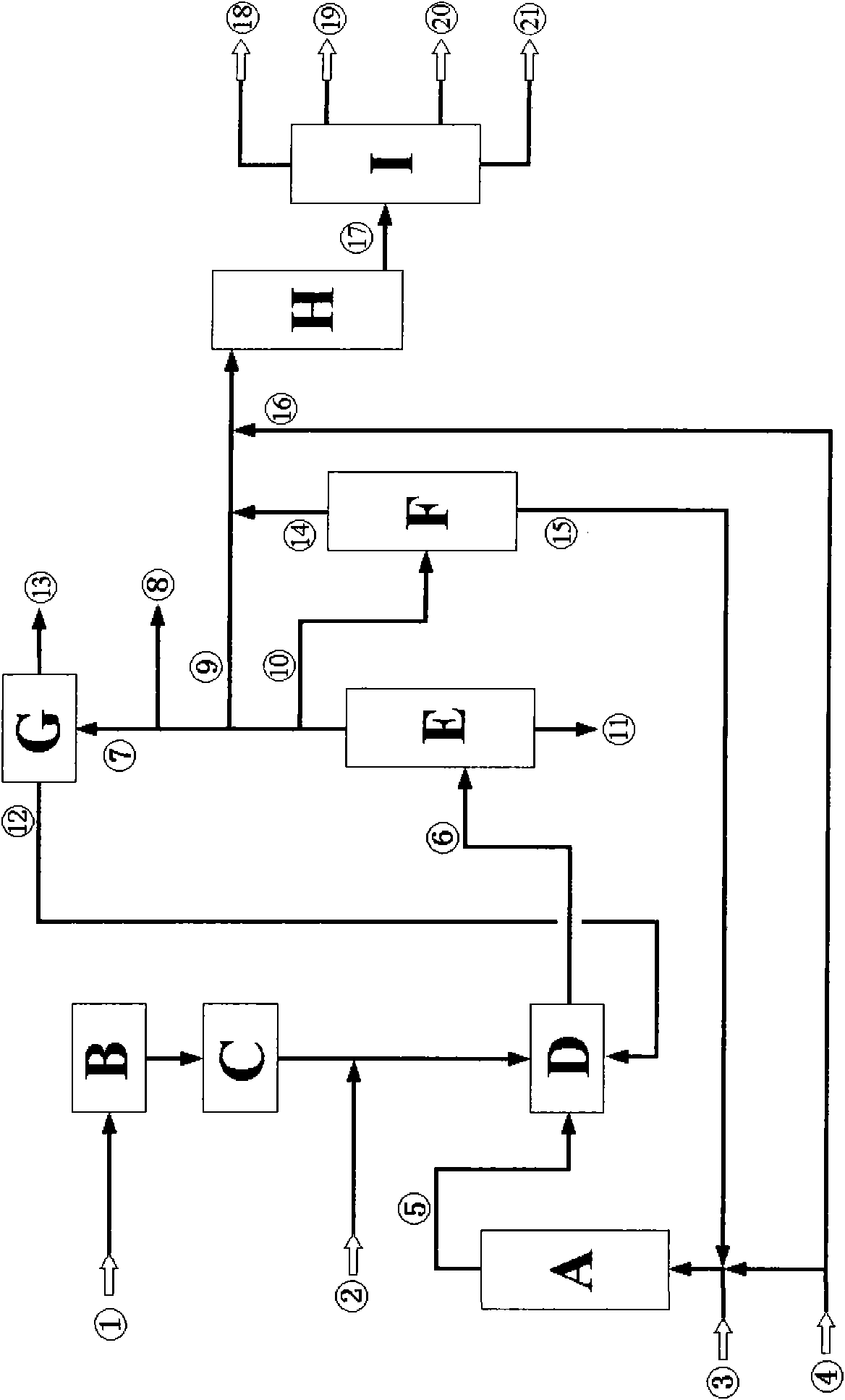

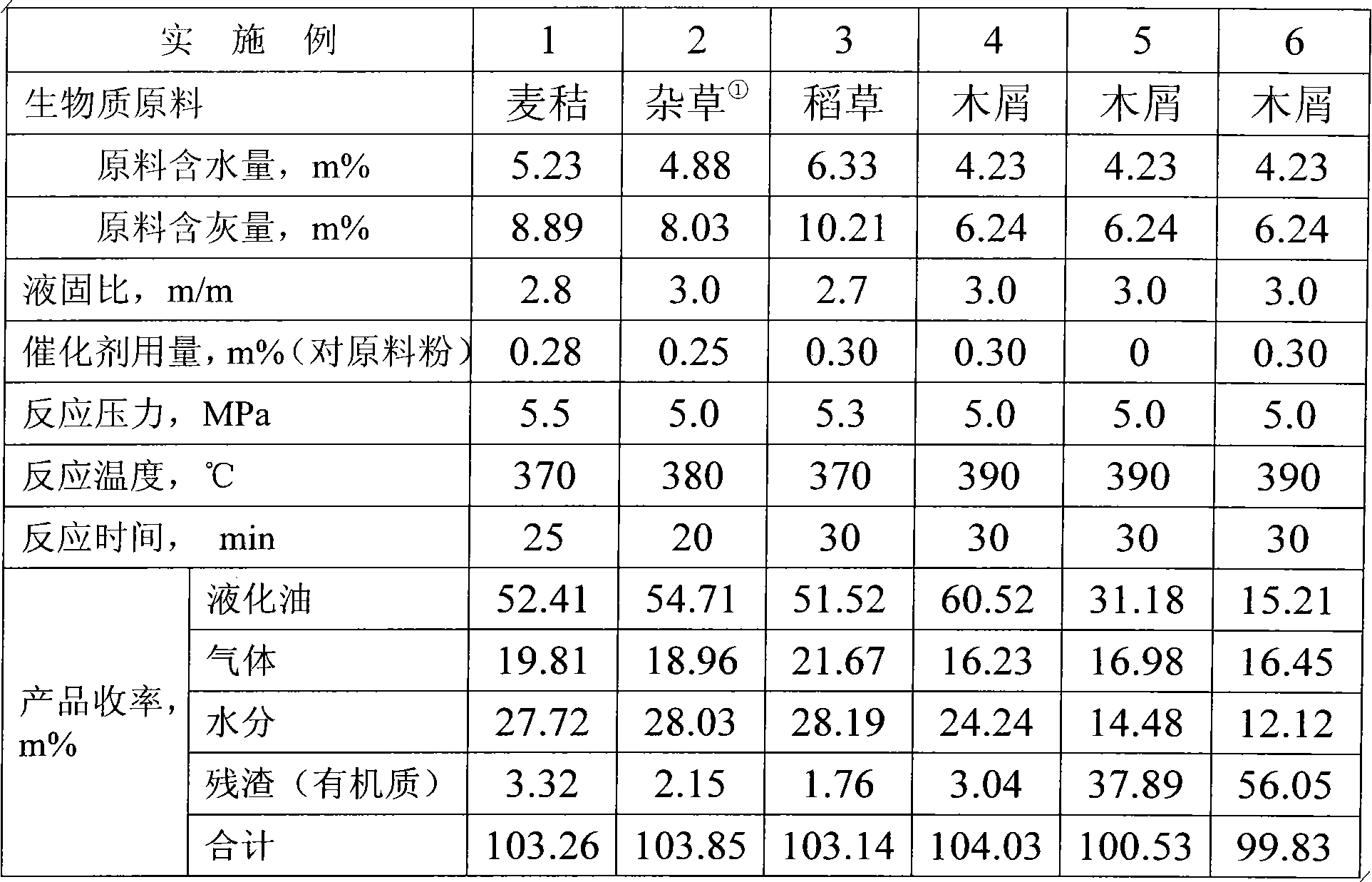

[0056] Embodiment Using wheat straw, weeds (including about 35m% of shrub branches and leaves), rice straw, and mixed sawdust as raw materials, 100% sieved 180-mesh biomass raw material powder was made. Using the liquid catalyst described in the present invention, using the nonionic surfactant described in the present invention as an auxiliary agent, and using hydrogenated anthracene oil with a distillation range of 320°C to 400°C as a solvent, direct liquefaction of biomass supplied with hydrogen by solvent test. The present invention implements totally 12 examples, adopts figure 2 The process flow shown is all batch operation.

[0057] Embodiments 1-3 are preferred reaction conditions and test results of the present invention.

Embodiment 4

[0058] Examples 4-6 are compared as other conditions are preferred, but there is no catalyst / solvent and no hydrogen-donating effect. Wherein embodiment 5 does not use catalyst, but uses hydrogenated anthracene oil as a solvent; embodiment 6 adopts the same catalyst as embodiment 4, but uses no hydrogen-donating solvent (anthracene oil without hydrogenation treatment) as the reaction medium.

[0059] Examples 7-12 are boundary or near boundary reaction conditions and test results of the present invention.

[0060] The catalyst composition of each embodiment is as follows:

Embodiment 1

[0061] Embodiment 1 / 7 / 8: 6m% of ammonium molybdate, 8.5m% of nickel nitrate, 13m% of ferrous sulfate, 7m% of ferric sulfate, 4.5m% of polysorbate, 5.5m% of sorbitan monooleate , alkyl polyglucoside 2m%, and the rest is distilled water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com