Test strip for fast detecting premature rupture of fetal membranes

A technology for detecting test strips and premature rupture of membranes, applied in the field of medical testing, can solve the problems of inability to judge the time and stage of rupture of fetal membranes, difficult to achieve quantitative detection, complicated purification process, etc., to achieve easy-to-read and optimized results. Preparation method and effect of improving detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 Premature rupture of membranes color latex rapid detection test strip

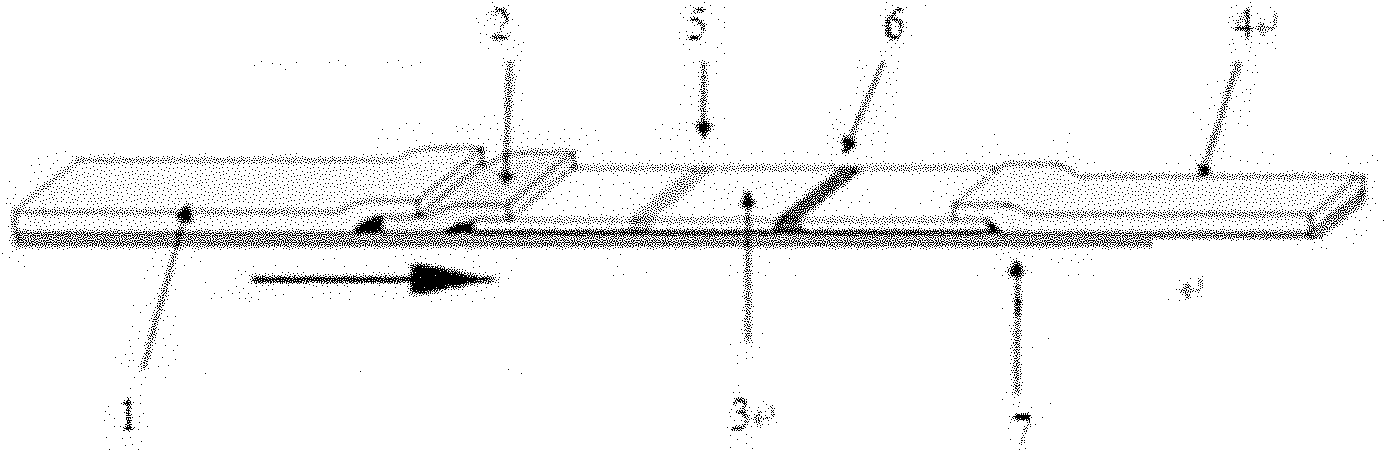

[0033] like figure 1 As shown, the rapid detection test strip for premature rupture of membranes according to the present invention, the test strip is that the sample pad 1 is pasted on the backing 7 in sequence, and the colored latex particles are coated with the IGFBP-1 monoclonal antibody. Made of glass fiber membrane 2, coating membrane 3 and absorbent paper 4, the coating membrane 3 has a detection area 5 and a control area 6, the detection area 5 is coated with anti-IGFBP-1 monoclonal antibody, and the control area 6 is coated with anti-mouse antibody.

[0034] The ratio of IGFBP-1 monoclonal antibody to latex particles is 10 μg / 100 μl, and the dilution parameter of latex particle-labeled IGFBP-1 monoclonal antibody coated on glass fiber membrane is 25 cm 2 / ml. The concentration of anti-IGFBP-1 specific monoclonal antibody and anti-mouse antibody was 10 μg / ml, and the amount used ...

Embodiment 2

[0051] Example 2 Premature Rupture of Membranes Magnetic Latex Rapid Detection Test Strip

[0052] The detection test strip in this embodiment is the same as the embodiment 1 except that the glass fiber membrane 2 is coated with the magnetic latex-labeled IGFBP-1 monoclonal antibody. The magnetic latex particles are core-shell silica magnetic microspheres, the surface group is carboxyl (-COOH), solid content: 10%, particle size: 500nm (deviation<10%), and magnetic content is 20%.

[0053] The ratio of IGFBP-1 monoclonal antibody to magnetic latex particles is 100 μg / 100 μl, and the dilution parameter of latex particle-labeled IGFBP-1 monoclonal antibody coated on glass fiber membrane is 30 cm 2 / ml. The concentration of anti-IGFBP-1 specific monoclonal antibody and anti-mouse antibody was 10 μg / ml, and the amount used in the detection zone and control zone was 20 μl / 35cm.

[0054] The preparation method of the detection test strip in this embodiment is:

[0055] 1. Preparat...

Embodiment 3

[0065] Example 3 Fluorescent latex rapid detection test strip for premature rupture of membranes

[0066] In the detection test strip in this embodiment, the glass fiber membrane 2 is coated with fluorescent latex-labeled IGFBP-1 monoclonal antibody, and the other structures are the same as in Embodiment 1. The fluorescent latex particles are coupled with the IGFBP-1 antibody, and the quantitative detection of IGFBP-1 is realized through the relationship curve of the antibody coupling amount, the concentration of the antibody drawn on the detection line and the detection signal.

[0067] Among them, the fluorescent latex particles are fluorescent polymer microspheres formed by combining fluorescein and a polymer with styrene as a monomer, with an average particle size of 200-250nm and a maximum excitation wavelength of 550nm.

[0068] The ratio of IGFBP-1 monoclonal antibody to fluorescent latex particles is 50 μg / 100 μl, and the dilution parameter of fluorescent latex particl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com