Method for preparing nitrogen-phosphorus codoped multi-walled carbon nanotube

A technology of multi-walled carbon nanotubes and co-doping, which is applied in the direction of nanotechnology, can solve the problem of preparation of multi-walled carbon nanotubes without nitrogen and phosphorus co-doping, does not involve nitrogen-phosphorus co-doped multi-walled carbon nanotubes, does not involve Chemical vapor deposition and other problems, to achieve the effect of simple method, high output and strong operation controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Pave the bottom with 0.1g of FeMo / Al 2 o 3 Put the catalyst quartz boat into the high-temperature part of the quartz tube in the tube furnace, and raise the temperature of the high-temperature part of the quartz tube to 700°C under the protection of argon inert gas with a flow rate of 1.0L / min;

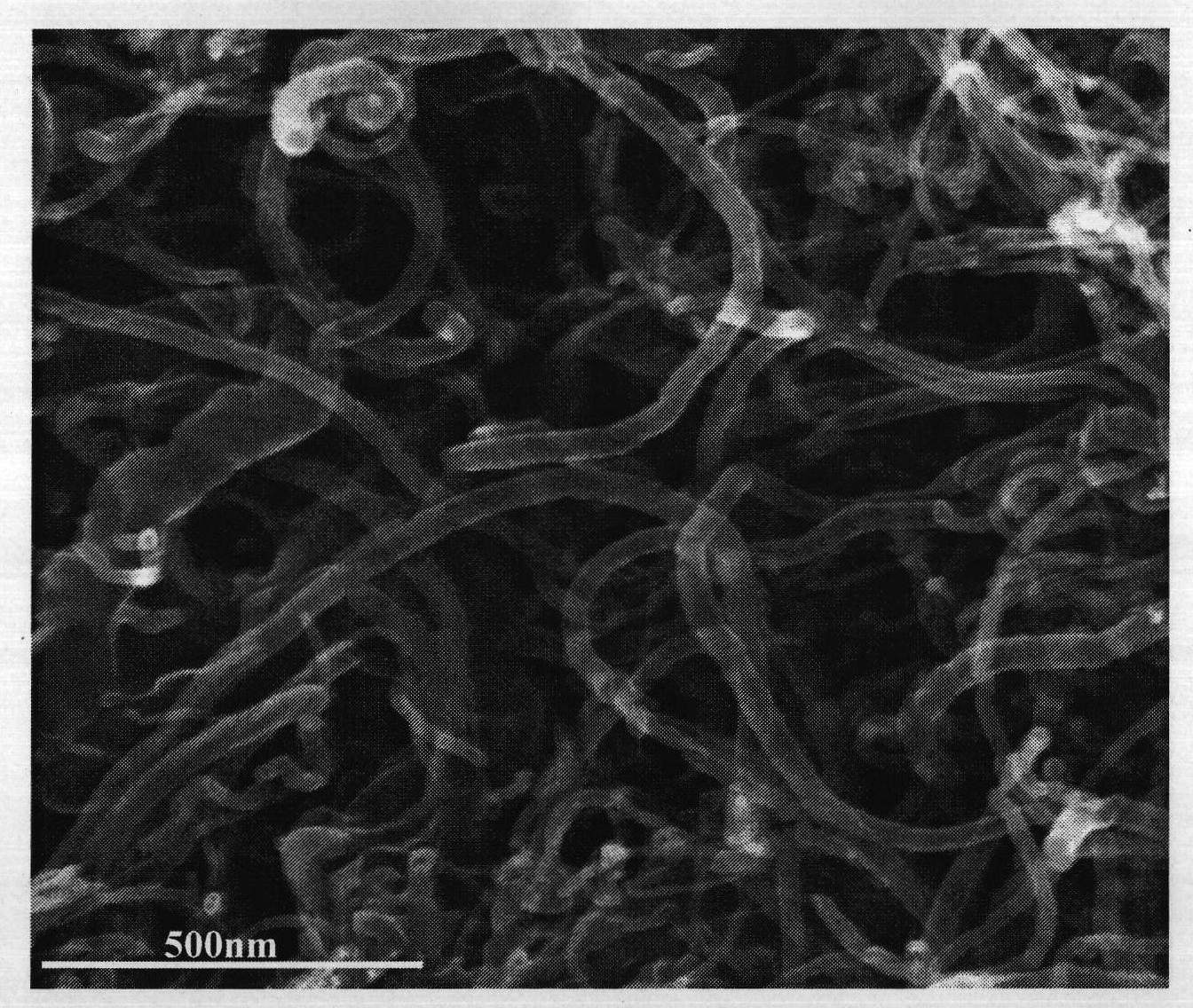

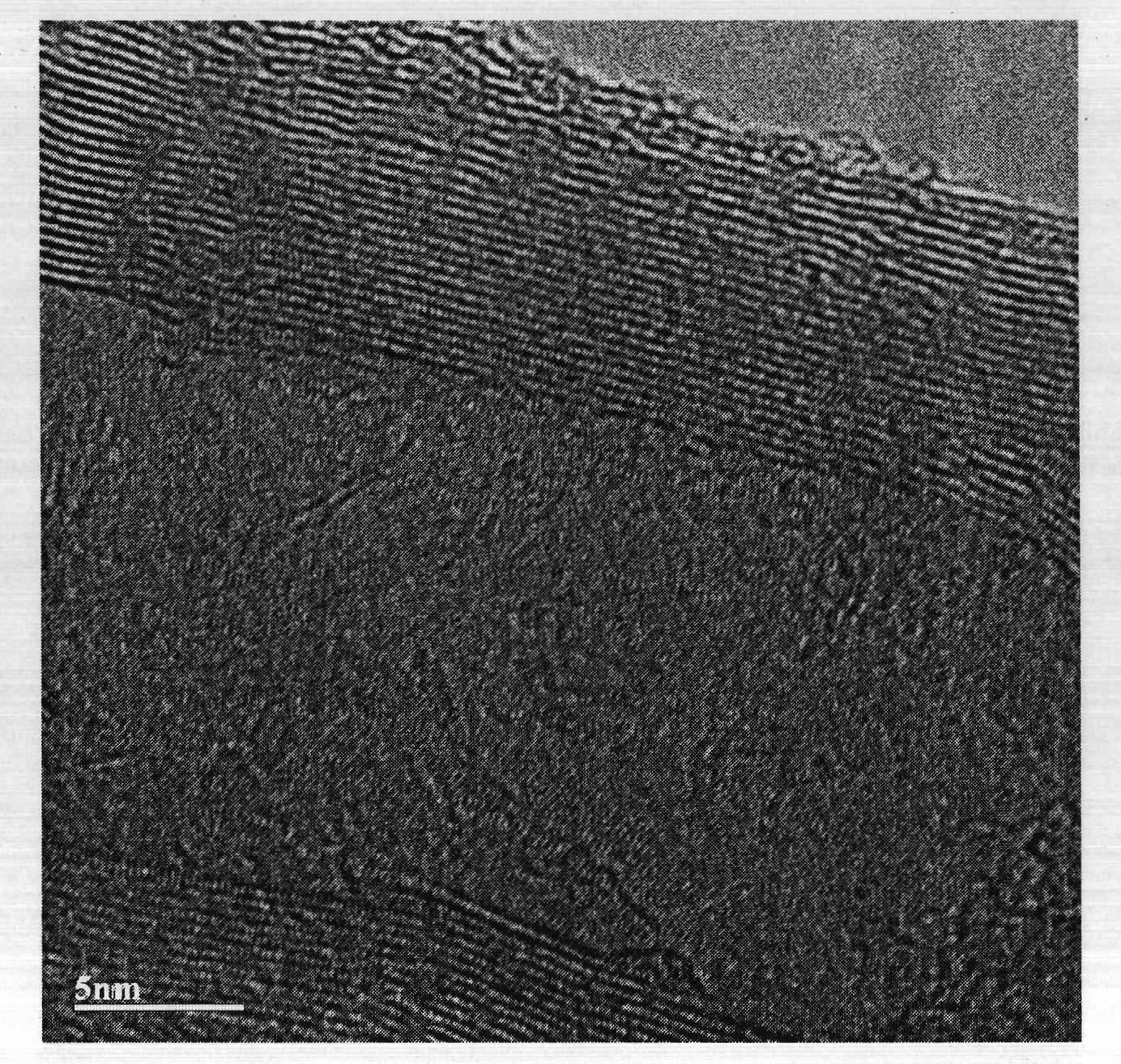

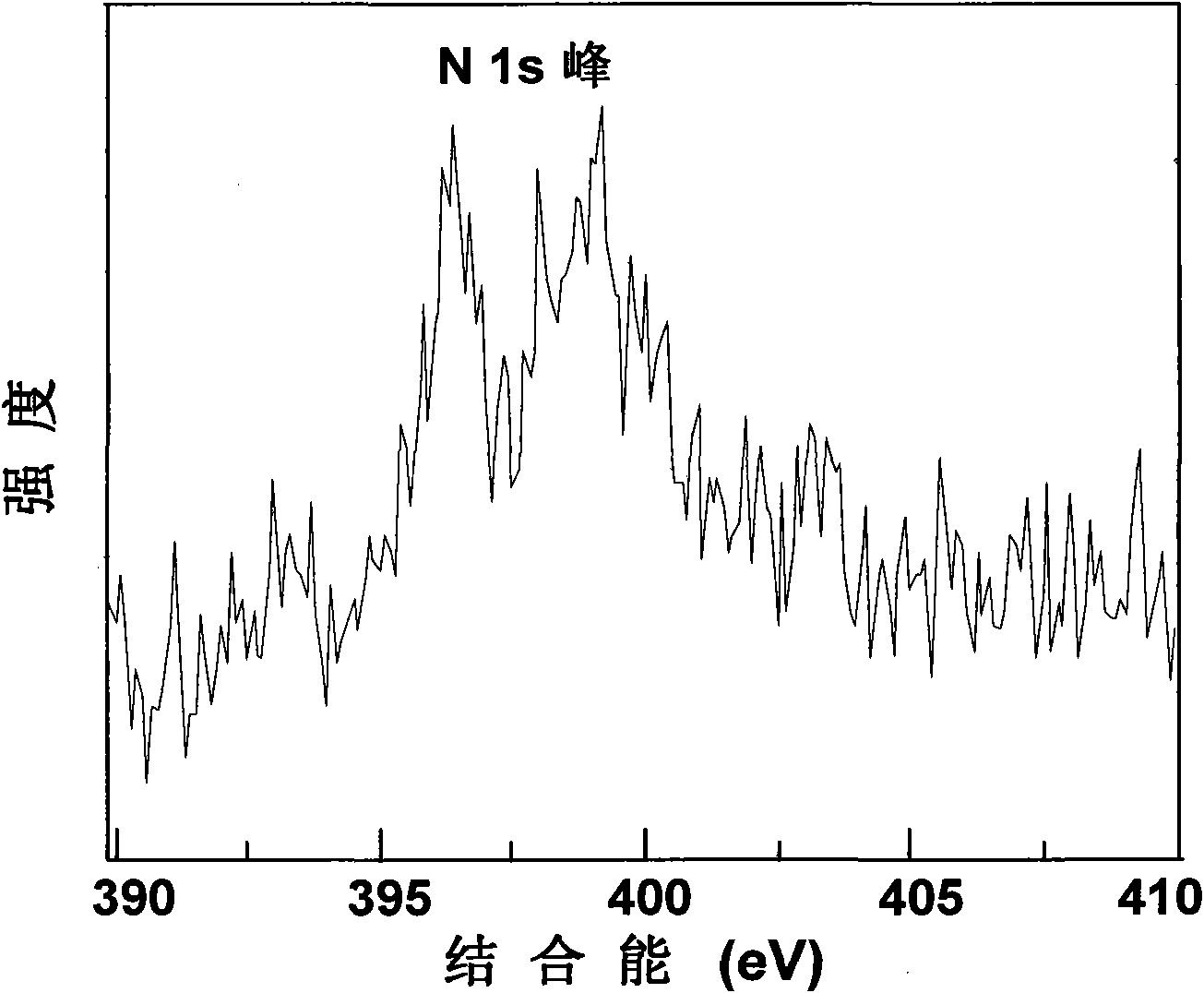

[0028] 2) Add 8mL of toluene to the container bottle, and then slowly add triphenylphosphine, wherein the amount of triphenylphosphine is 2.5wt% toluene; after the triphenylphosphine is completely dissolved, replace the argon gas with a flow rate of 200ml / min Ammonia, under the ammonia atmosphere, inject the mixed solution into the quartz tube through a constant flow pump at a flow rate of 2mL / h. After the solution is vaporized, it is brought to the high temperature area by the ammonia gas. Carbon source toluene, nitrogen source ammonia and phosphorus The source triphenylphosphine is decomposed, and the solid catalyst FeMo / Al 2 o 3 Under the action, nitrogen and phosphoru...

Embodiment 2

[0031] 1) Pave the bottom with 0.1g of FeMo / Al 2 o 3 Put the catalyst quartz boat into the high-temperature part of the quartz tube in the tube furnace, and raise the temperature of the high-temperature part of the quartz tube to 700°C under the protection of argon inert gas with a flow rate of 1.0L / min;

[0032] 2) Add 10mL of toluene to the container bottle, and then slowly add triphenylphosphine, wherein the amount of triphenylphosphine is 5wt% toluene; after the triphenylphosphine is completely dissolved, replace the argon gas with a flow rate of 400ml / min Ammonia, under an ammonia atmosphere, inject the mixed solution into the quartz tube through a constant flow pump at a flow rate of 3mL / h. After the solution is vaporized, it is brought to the high temperature area by argon. Carbon source toluene, nitrogen source ammonia and phosphorus The source triphenylphosphine is decomposed, and the solid catalyst FeMo / Al 2 o 3 Under the action, nitrogen and phosphorus co-doped m...

Embodiment 3

[0035] 1) Pave the bottom with 0.1g of FeMo / Al 2 o 3 Put the catalyst quartz boat into the high-temperature part of the quartz tube in the tube furnace, and raise the temperature of the high-temperature part of the quartz tube to 800°C under the protection of argon inert gas with a flow rate of 1.3L / min;

[0036] 2) Add 12mL of toluene to the container bottle, and then slowly add triphenylphosphine, wherein the amount of triphenylphosphine is 10wt% toluene; after the triphenylphosphine is completely dissolved, replace the argon gas with a flow rate of 500ml / min ammonia Under the atmosphere of ammonia gas, inject the mixed solution into the quartz tube at a flow rate of 3mL / h through a constant flow pump. After the solution is vaporized, it is brought to the high temperature area by ammonia gas. Triphenylphosphine decomposes on the solid catalyst FeMo / Al 2 o 3 Under the action, nitrogen and phosphorus co-doped multi-walled carbon nanotubes began to grow;

[0037] 4) After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com