Production method of low density foam carbon heat insulating material for inert atmosphere furnace

A technology for thermal insulation materials and production methods, applied in applications, household appliances, and other household appliances, etc., can solve the problems of failure to obtain favorable changes in performance and products that have not been recognized by the market, and achieve simple and easy production methods and heat insulation The effect of excellent performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

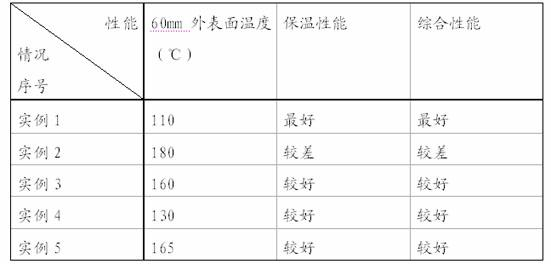

Examples

Embodiment 1

[0025] First, 100 parts of PF4023 resin, 1 part of polyvinyl alcohol, 8 parts of 3-3'-disulfonyl hydrazide diphenyl sulfone, 8 parts of hexamethylenetetramine, 2 parts of polyvinyl acetal Mix with 1 part of KH550; then, add 55 parts of graphite powder, 20 parts of carbon fiber scraps and 5 parts of expandable graphite to the well-mixed PF4023 resin, polyvinyl alcohol, 3-3'-disulfonyl Hydrazine diphenyl sulfone, hexamethylenetetramine, polyvinyl acetal and KH550 are mixed again; then, the uniformly mixed graphite powder, carbon fiber chips, expandable graphite, PF4023 resin, polyvinyl alcohol, 3- 3′-disulfonylhydrazide diphenyl sulfone, hexamethylenetetramine, polyvinyl acetal and KH550 are loaded into the mold, and then put into the oven for foaming treatment. The process of foaming treatment includes: 50 minutes Raise the temperature to 80°C for 50 minutes, then raise the temperature to 130°C for 10 minutes in 30 minutes, then raise the temperature to 160°C in 30 minutes, kee...

Embodiment 2

[0027] First, mix 100 parts of PF4401 resin, 5 parts of 3-3'-disulfonyl hydrazide diphenylsulfone, 5 parts of 4-4'-oxobisbenzenesulfonyl hydrazide and 9 parts of m-phenylenediamine ; Then, 30 parts of pitch coke and 30 parts of quartz fiber chips are added to the mixed PF4401 resin, 3-3'-disulfonyl hydrazide diphenyl sulfone, 4-4'-oxobisbenzenesulfonyl hydrazide and m-phenylenediamine and then mixed; then, the uniformly mixed pitch coke, quartz fiber scraps, expandable graphite, PF4401 resin, 3-3'-disulfonylhydrazide diphenyl sulfone, 4-4'-oxobis Put benzenesulfonyl hydrazide and m-phenylenediamine into the mold, and then put them into the oven for foaming treatment. The foaming treatment process includes: heating up to 80°C for 30 minutes and holding for 40 minutes, then raising the temperature to 130°C for 50 minutes Keep warm for 30 minutes, then take 20 minutes to raise the temperature to 160°C, keep hold for 20 minutes, then take 40 minutes to raise the temperature to 180...

Embodiment 3

[0029]First, 100 parts of PF1102 resin, 2 parts of hydroxyethyl cellulose, 7 parts of 4-4'-oxobisbenzenesulfonyl hydrazide, 5 parts of hexamethylenetetramine and 5 parts of isophthalic acid Amines are mixed; then, 50 parts of petroleum coke and 25 parts of aluminum silicate fiber chips are added to the well-mixed PF1102 resin, hydroxyethyl cellulose, 4-4'-oxobisbenzenesulfonyl hydrazide, six times Methyltetramine and m-phenylenediamine are mixed again; then, uniformly mixed petroleum coke, aluminum silicate fiber chips, expandable graphite, PF1102 resin, hydroxyethyl cellulose, 4-4'-oxobis Benzenesulfonyl hydrazide, hexamethylenetetramine and m-phenylenediamine are loaded into the mold, and then put into an oven for foaming treatment, wherein the process of foaming treatment includes: heating up to 80°C for 100 minutes and keeping it warm for 30 minutes, and then Take 40 minutes to raise the temperature to 130°C and keep it for 20 minutes, then take 40 minutes to raise the tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com