Method for preparing magneto-optic difunctional CNT/Fe304@SiO2 (FITC) (Fluorescein Isothiocyanate) one-dimensional nano composite material

A nano-composite material and dual-function technology, which is applied in the direction of luminescent materials, inorganic material magnetism, chemical instruments and methods, etc., can solve the problems of no luminous performance, etc., and achieve good response, convenient operation, and high luminous intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

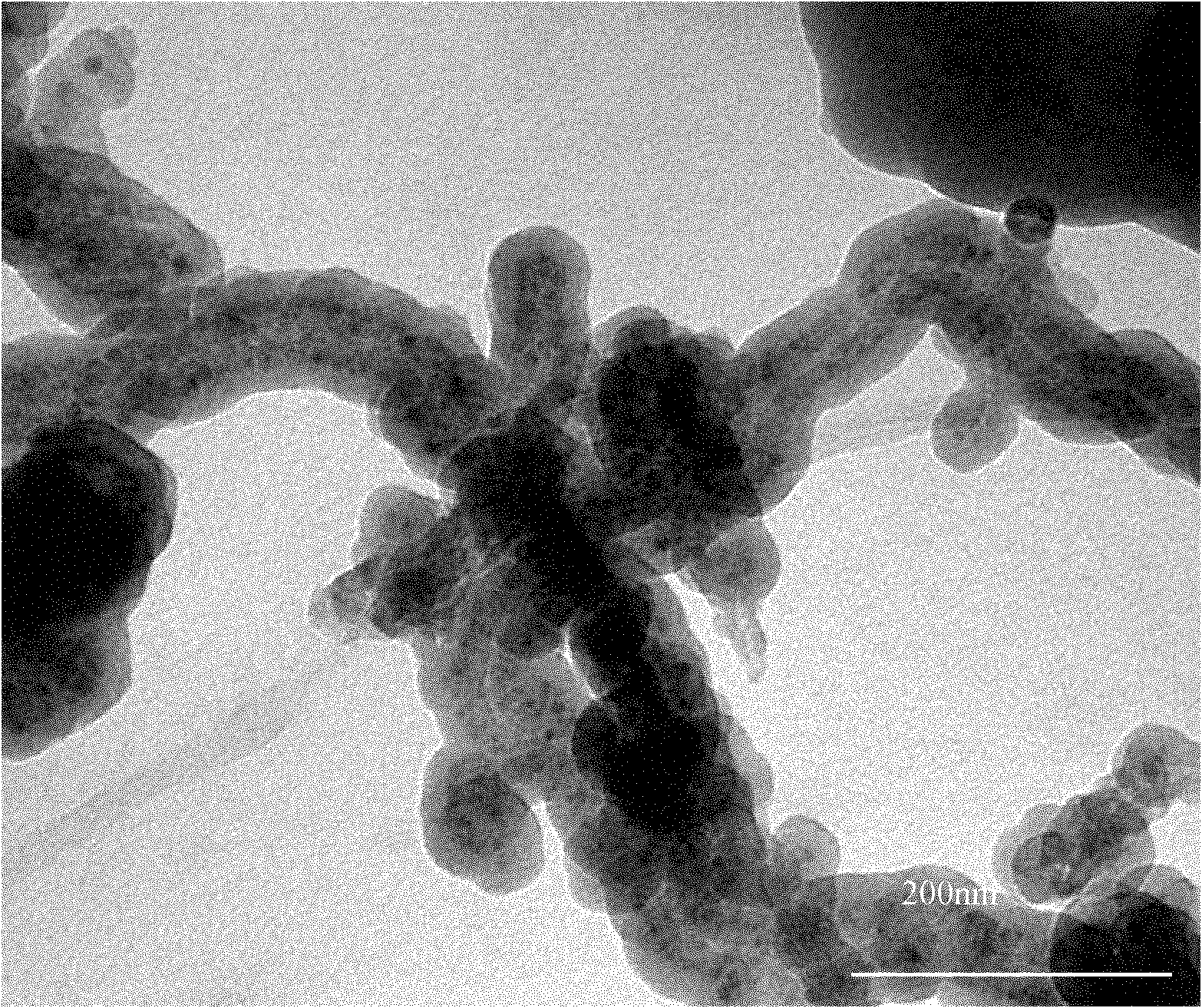

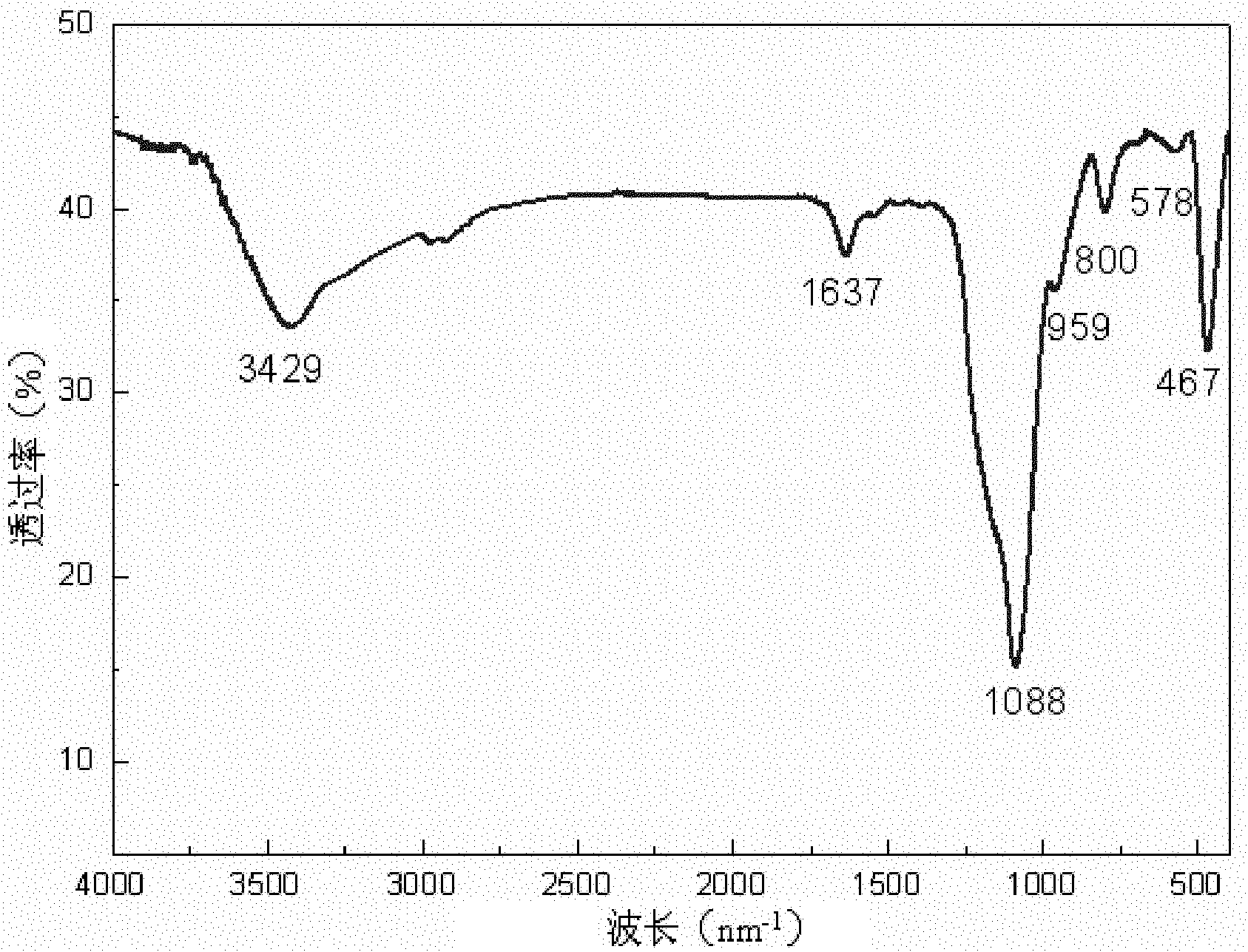

[0007] Specific implementation mode 1: In this implementation mode, the magneto-optic bifunctional CNT / Fe 3 o 4 @SiO 2 The preparation method of (FITC) one-dimensional nanocomposite material is to carry out according to the following steps: 1. Weigh 150mg of multi-walled carbon nanotubes, 50-100mg of iron acetylacetonate and 25mL of triethylene glycol, mix them, and then ultrasonically disperse them until they are uniform. 100-200mL / min gas flow rate into the argon for 5 minutes, then heated to the boiling point of triethylene glycol (278 ℃) at a temperature increase rate of 5 ℃ / min reflux 30-60 min, cooled and washed with absolute ethanol 4 times, magnetic separation , and dry to get CNT / Fe 3 o 4 ; 2. Take 10 mg of fluorescein isothiocyanate molecule, 0.5-2 mL of APS silane coupling agent and 8 mL of absolute ethanol, mix them, and stir for 12 hours under the protection of Ar gas in the dark to obtain APS-FITC, and put it in a refrigerator at 3 °C 3. Take 20 mg of CNT / F...

specific Embodiment approach 2

[0008] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the power used for the ultrasonic dispersion in Step 1 is 150W, and the ultrasonic dispersion requires 10 minutes. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0009] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the drying time in step 1 is 10 hours and the drying temperature is 45°C. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com