Method for synthesizing graphene-containing composite thin film material

A graphene composite, graphene film technology, applied in electrolytic coatings, electrophoretic plating, coatings, etc., can solve problems such as pollution, and achieve the effect of improving catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

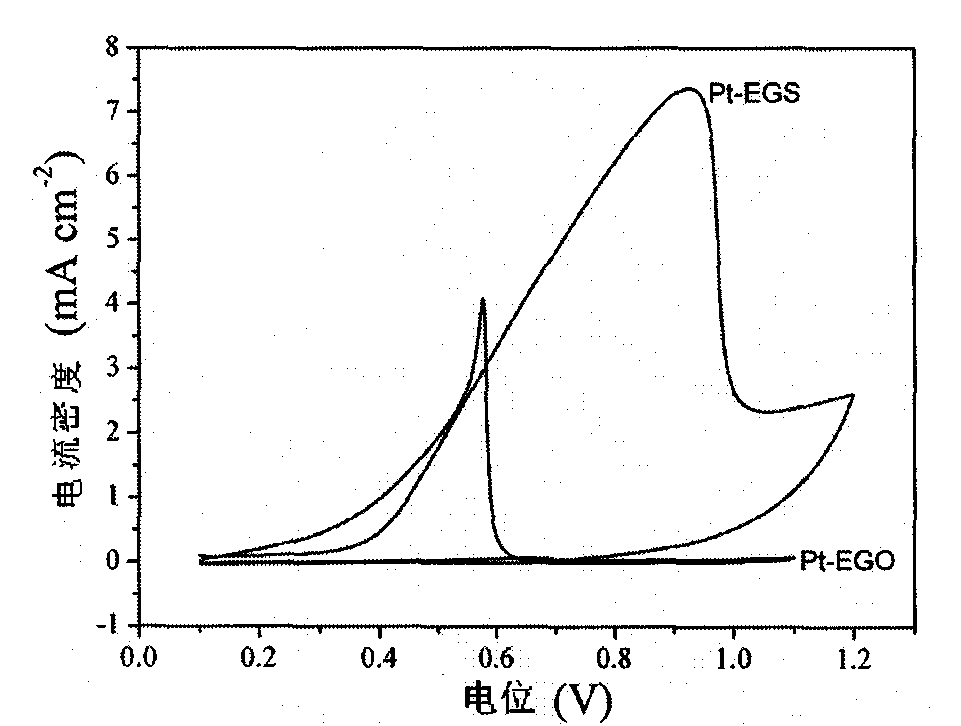

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1.1 Treatment of Conductive Glass Substrate

[0026] First, cut the conductive glass into 15mm×25mm, ultrasonically clean it with distilled water and ethanol for 30 minutes, and dry it with nitrogen.

[0027] 1.2 Electrophoretic deposition of graphene oxide film on the surface of conductive glass

[0028] Conductive glass is used as the anode, a stainless steel sheet of the same size is used as the cathode, the graphene oxide suspension is used as the deposition medium, and the deposition is performed at 150-160V for 45-60 seconds.

[0029] 1.3 Graphene film obtained by cyclic voltammetry reduction of graphene oxide

[0030] The graphene oxide film was used as the working electrode, the silver-silver chloride electrode and the platinum wire electrode were used as the reference electrode and the auxiliary electrode, respectively, and 0.1mol L -1 Aqueous KCl solution is an electrolyte solution, within the range of 0.0V-1.0V at 10mV s -1 The scanning speed is scanned 10...

Embodiment 2

[0036] 2.1 Treatment of Conductive Glass Substrate

[0037] First, cut the conductive glass into 15mm×25mm, ultrasonically clean it with distilled water and ethanol for 30 minutes, and dry it with nitrogen.

[0038] 2.2 Electrophoretic deposition of graphene oxide film on the surface of conductive glass

[0039] Conductive glass is used as the anode, a stainless steel sheet of the same size is used as the cathode, the graphene oxide suspension is used as the deposition medium, and the deposition is performed at 150-160V for 45-60 seconds.

[0040] 2.3 Reduction of graphene oxide by potentiostatic method to obtain graphene film

[0041] The graphene oxide film was used as the working electrode, the silver-silver chloride electrode and the platinum wire electrode were used as the reference electrode and the auxiliary electrode, respectively, and 0.1mol L -1 The KCl aqueous solution is an electrolyte solution, and the graphene oxide film is reduced at a constant potential of -0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com