Method for preparing sun-proof micelle emulsifier

An emulsifier and micelle technology, applied in cosmetic preparations, preparations for skin care, cosmetics, etc., can solve the problems of poor water and sweat resistance, high irritation, poor photothermal stability, etc., and achieve good application prospects, good Emulsifying performance, simple preparation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1 ionic random copolymer P (VM- co -AMPS) preparation

[0022] Take AMPS 7.8g (37.5mmol) and VM 3.6g (12.5mmol) to dissolve in 15mL DMF, stir through N 2 After 15 minutes, add AET 0.34g (3mmol) and AIBN 0.16g (1mmol), and then pass N 2 15min, then seal the bottle mouth, transfer to 70 ℃ oil bath, after reacting for 8 hours, take the cup substrate, precipitate in acetone, dissolve in water, freeze-dry after dialysis to obtain pure random copolymer P(VM- co -AMPS).

Embodiment 2

[0023] Example 2 P(VM- co -AMPS) micelles preparation

[0024] Weigh the polymer P(VM- co -AMPS) 5 mg, dissolved in 100 mL of water, stirred for 1 hour to obtain a micellar solution with a concentration of 0.05 mg / mL.

Embodiment 3

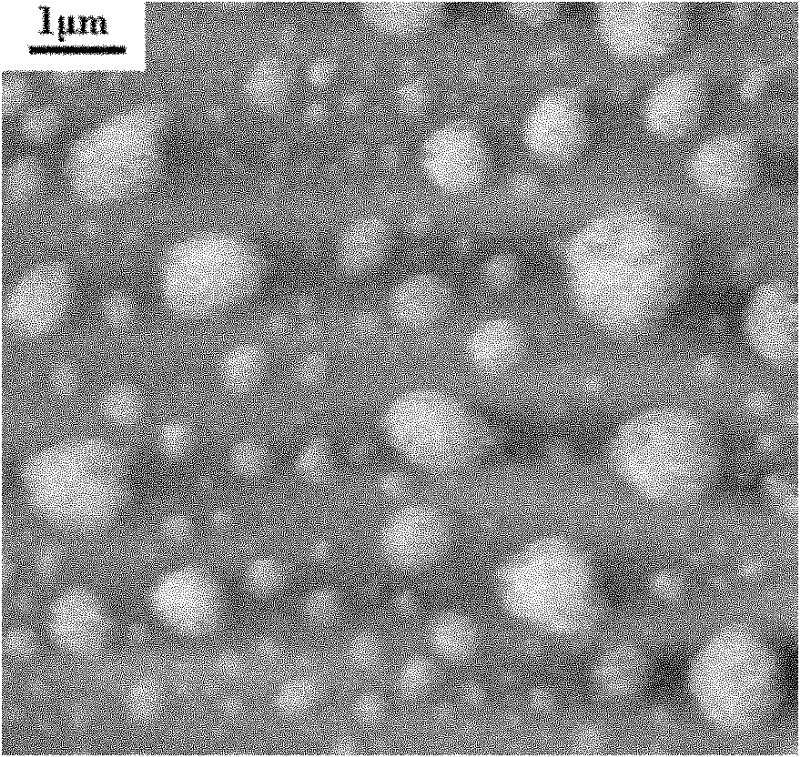

[0025] Example 3 P(VM- co -AMPS) micellar morphology

[0026] Take 0.05mg / mL of P(VM- co -AMPS) micellar solution 5mL, drop on the mica sheet and dry at room temperature for 48 hours, observe the morphology of the micelles under the atomic force microscope. figure 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com