Method for quickly detecting harmful bacteria in beer

A harmful bacteria and fast technology, applied in the field of beer, can solve the problems of inability to provide contaminating bacteria in breweries, unable to characterize, unable to distinguish, etc., to facilitate experimental observation and counting, to observe intuitively, and to avoid false positives and false negatives.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

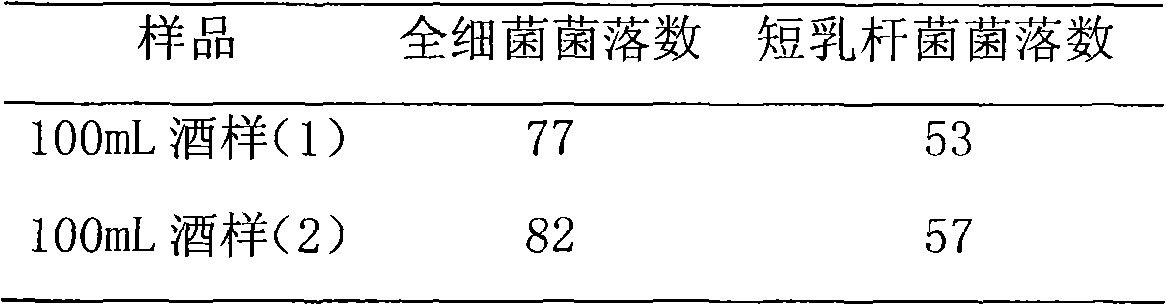

Embodiment 1

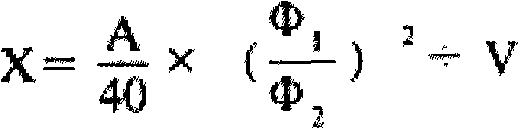

[0025] Take 1 bottle (600mL) of capped sake from a production workshop of a brewery, and after suction-filtering 100mL wine sample, take out the filter membrane and paste it on the rapid growth medium (peptone 8g, yeast extract 6g, beef extract 6g, spit temperature 800.8g, dipotassium hydrogen phosphate 2g, sodium acetate 6g, folic acid 0.2g, cycloheximide 6mg, agar 15g, glucose 15g, malt root extract powder 0.5g, calcium pantothenate 0.4g) plate, put After anaerobic culture in an anaerobic tank for 16 hours, perform fluorescent staining, place the polycarbonate membrane on sterile filter paper soaked in CFDA staining solution, and stain in the dark for 12 minutes, then take it out and place it in a sterile filter paper soaked in sterile water. Wash the staining solution under the membrane on the filter paper, then perform fluorescence in situ hybridization on the membrane according to the experimental procedure, add 10 μL volume of pre-designed Cy3-labeled Lactobacillus brevis...

Embodiment 2

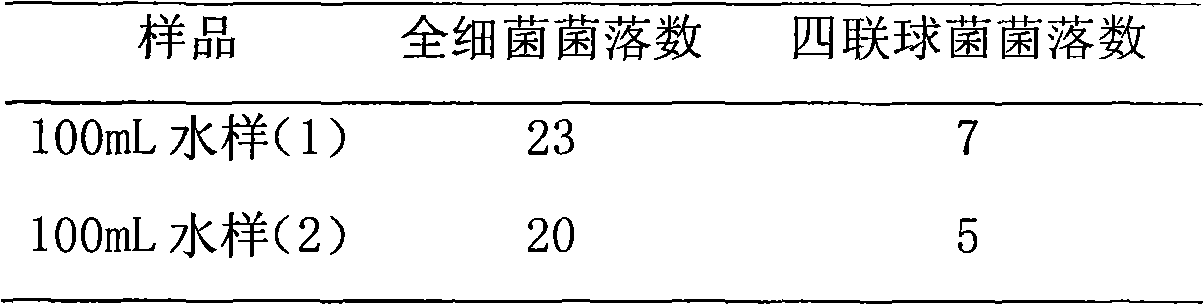

[0030] Take 100mL of water from the production workshop of a brewery, filter the water sample, take out the filter membrane and paste it on the nutrient agar plate with the bright side up, and perform fluorescent staining after aerobic cultivation at 36°C for 5 hours, and put the polycarbonate membrane on the Wet the sterile filter paper soaked in CFDA staining solution, and stained in the dark for 12 minutes, then took it out and put it on the sterile filter paper soaked in sterile water to wash off the staining solution under the membrane, and then carried out the fluorescence of the membrane according to the experimental procedure In situ hybridization operation, wherein the fluorescent probe is a Cy3-labeled tetrad probe. After the treatment is completed, observe under the Olympus BX41 microscope, and record the experimental results.

[0031]

[0032] This method can quickly detect the number of microorganisms and the most common contamination of tetrad bacteria in beer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com