Beta irradiation detector based on silicon carbide junction field-effect transistor (JFET)

A technology of irradiation detectors and silicon carbide junctions, which is applied in the directions of radiation intensity measurement, semiconductor devices, sustainable manufacturing/processing, etc., can solve the problems of weakening device detection capabilities, reducing channel currents, etc., and eliminate surface trap effects , Improving device performance and strong radiation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

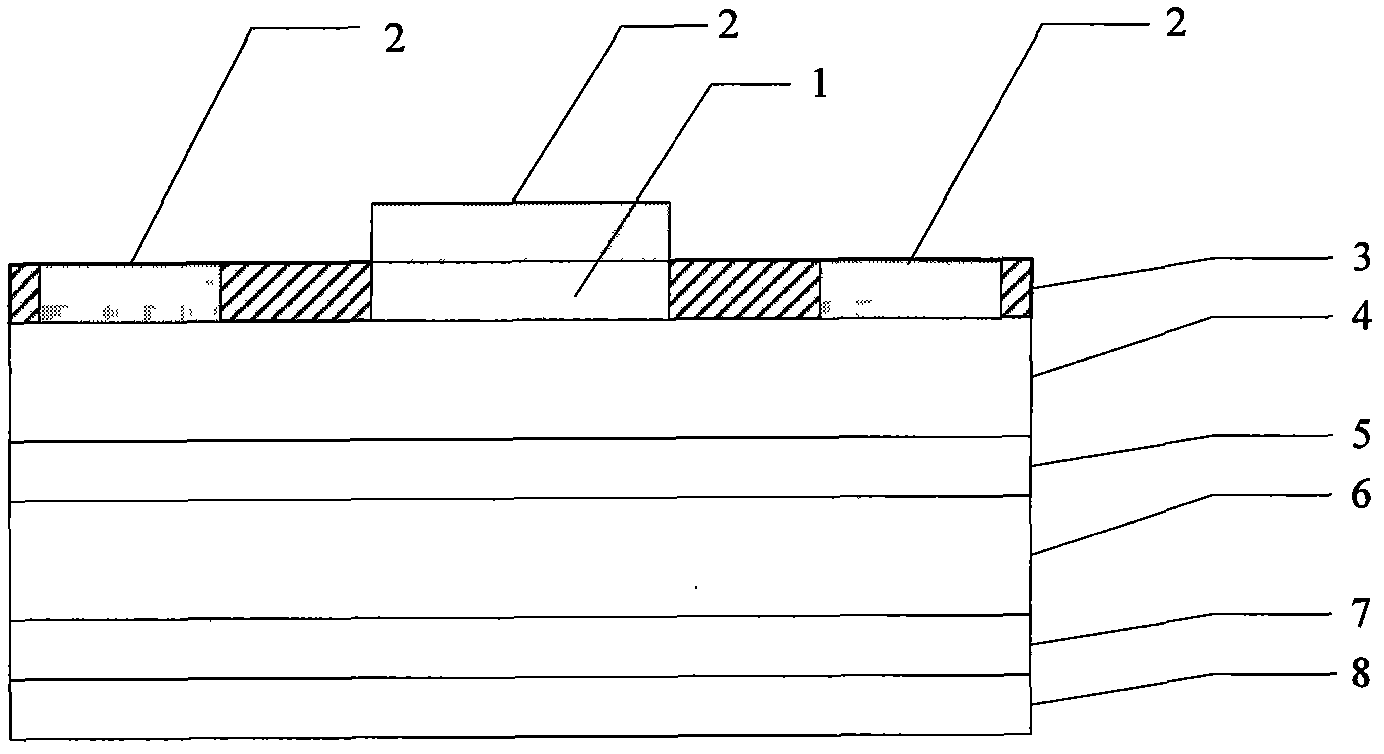

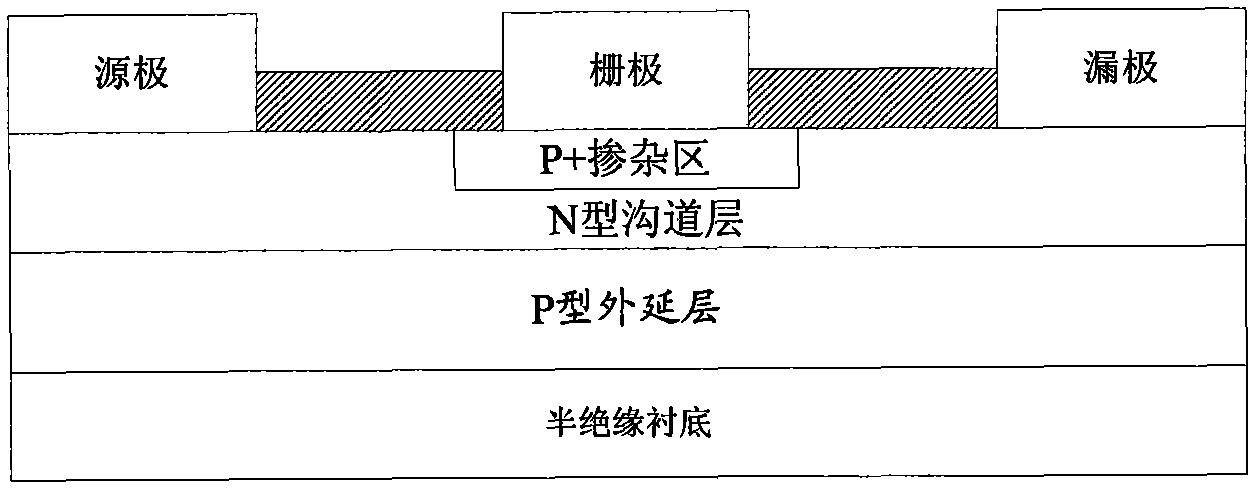

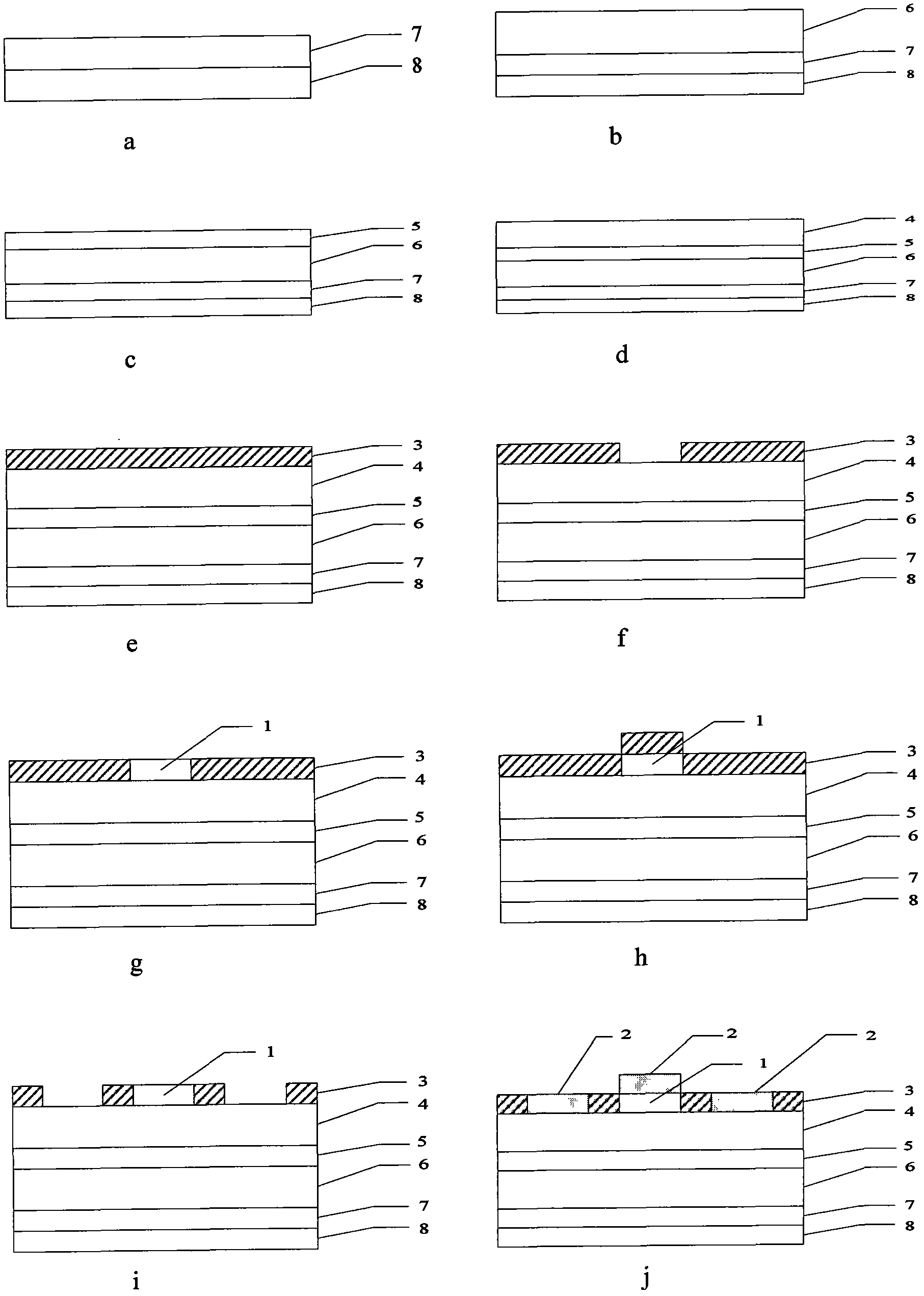

[0032] Step 1. Use a doping concentration of 5×10 17 cm -3 , an N-type 4H-SiC substrate with a thickness of 0.4 μm is used as the substrate 8, and the epitaxial growth doping concentration is 1.0×10 15 cm -3 , a P-type buffer layer 7 with a thickness of 0.1 μm, such as image 3 a, The epitaxy process conditions are: temperature is 1570°C, pressure is 100Mbar, growth gas is C 3 h 8 、SiH 4 and H 2 , where H 2 To carry gas.

[0033] Step 2. Epitaxial N-type channel 6 on the P-type buffer layer with a doping concentration of 1×10 16 cm -3 , with a thickness of 0.4 μm, such as image 3 b. The process conditions of the epitaxy are: temperature is 1570°C, pressure is 100Mbar, growth gas is C 3 h 8 、SiH 4 and H 2 , where H 2 To carry gas.

[0034] Step 3. The epitaxial doping concentration on the upper part of the N-type channel 6 is 1.0×10 15 cm -3 , an N-type buffer layer 5 with a thickness of 0.1 μm, such as image 3 c. The process conditions of the epitaxy are: ...

Embodiment 2

[0042] The first step uses a doping concentration of 5×10 17 cm -3 , an N-type 4H-SiC substrate with a thickness of 0.4 μm is used as the substrate 8, and the epitaxial growth doping concentration is 2.5×10 15 cm -3 , a P-type buffer layer 7 with a thickness of 0.15 μm, the epitaxy process conditions are temperature 1570°C, pressure 100Mbar, growth gas C 3 h 8 、SiH 4 and H 2 , where H 2 To carry gas, such as image 3 a;

[0043] In the second step, the epitaxial doping concentration on the P-type buffer layer is 1×10 16 cm -3 , an N-type channel 6 with a thickness of 0.4 μm, such as image 3 b. The process conditions of the epitaxy are: temperature is 1570°C, pressure is 100Mbar, growth gas is C 3 h 8 、SiH 4 and H 2 , where H 2 To carry gas.

[0044] In the third step, the epitaxial doping concentration on the upper part of the N-type channel 6 is 2.5×10 15 cm -3 , an N-type buffer layer 5 with a thickness of 0.15 μm, such as image 3 c. The process conditio...

Embodiment 3

[0052] Step A uses a doping concentration of 5×10 17 cm -3 , an N-type 4H-SiC substrate with a thickness of 0.4 μm is used as the substrate 8, and the epitaxial growth doping concentration is 5.0×10 15 cm -3 , a P-type buffer layer 7 with a thickness of 0.2 μm, the epitaxy process conditions are temperature 1570°C, pressure 100Mbar, growth gas C 3 h 8 、SiH 4 and H 2 , where H 2 To carry gas, such as image 3 a.

[0053] Step B epitaxial N-type channel 6 on the P-type buffer layer, the doping concentration is 1×10 16 cm -3 , with a thickness of 0.4 μm, such as image 3 b. The process conditions of the epitaxy are: temperature is 1570°C, pressure is 100Mbar, growth gas is C 3 h 8 、SiH 4 and H 2 , where H2 To carry gas.

[0054] In step C, the epitaxial doping concentration on the upper part of the N-type channel 6 is 5.0×10 15 cm -3 , an N-type buffer layer 5 with a thickness of 0.2 μm, such as image 3 c. The process conditions of the epitaxy are: temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com