Method for preparing high-temperature lithium manganate material for lithium ion power battery

A power battery, lithium manganate technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of rapid material capacity decay, material performance deterioration, poor cycle stability, etc., to achieve outstanding high temperature performance, improve uniformity performance, reliability, and comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

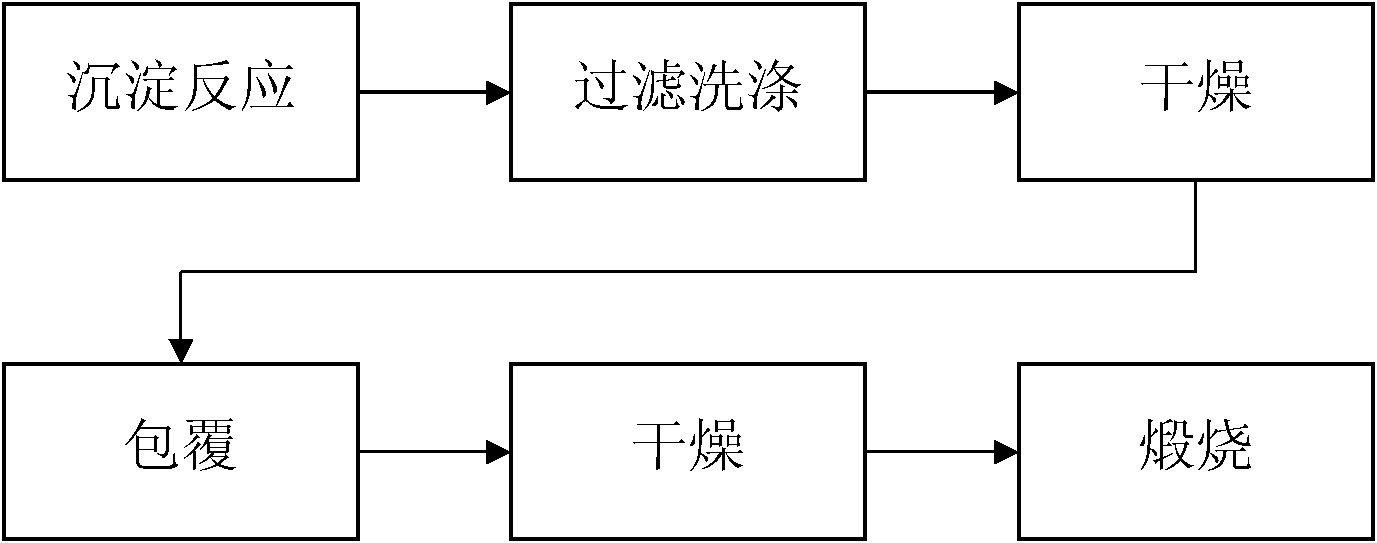

Method used

Image

Examples

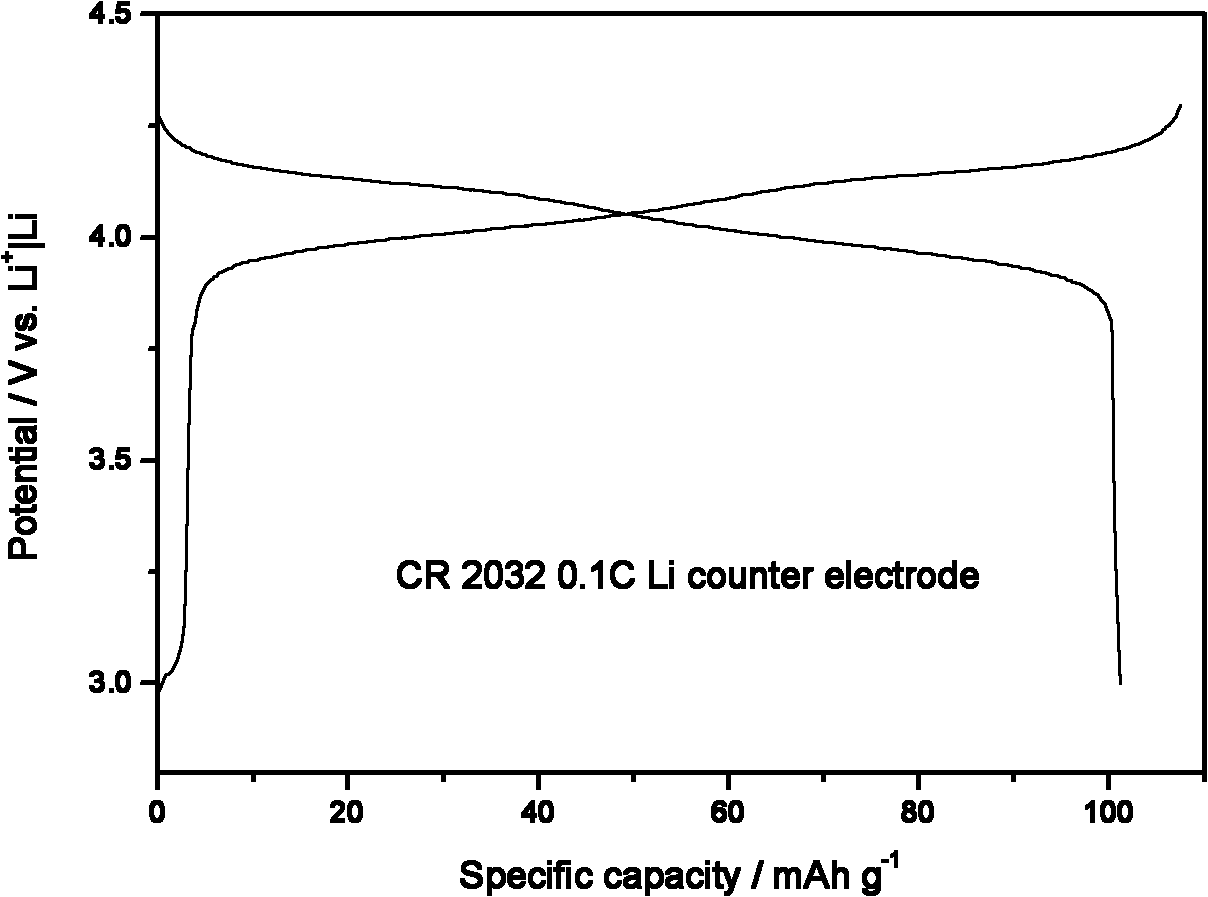

Embodiment 1

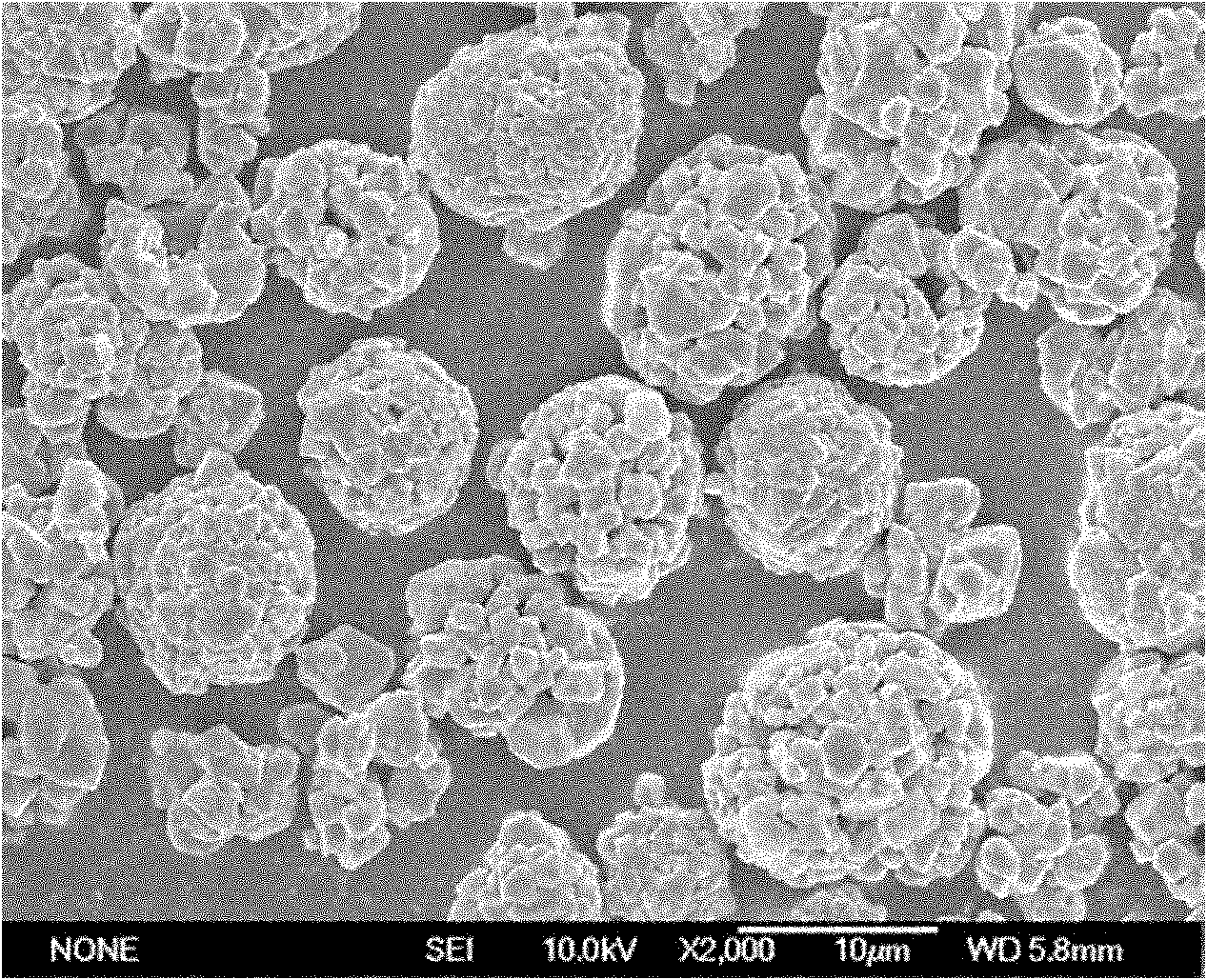

[0032] Prepare the following aqueous solutions for use: 1.5 mol / L (mol / L) manganese sulfate solution, 0.5 mol / L magnesium nitrate (dopant) solution, 2 mol / L sodium hydroxide solution, add 100 dm of sodium hydroxide solution per cubic meter 3 Concentrated ammonia. at 5m 3 Inject 200dm into the stirring constant temperature titanium-lined reactor 3 Pure water, start stirring, set the reaction temperature to 10°C, use a real-time pH automatic control device to control the injection of sodium hydroxide (containing ammonia water), and control the pH range of the system between 11 and 12. Use a metering pump to inject the manganese sulfate and magnesium sulfate solutions into the reactor at multiple points, and control the flow rate to 20dm respectively 3 min -1 and 1.54dm 3 min -1 , Stop injecting after 1.5h. After continuing to react for 1h, the material was discharged. Use a filter press to filter, fully press dry, wash the precipitate with pure water 10 times, press dry a...

Embodiment 2

[0035] Prepare the following aqueous solutions for use: 4mol / L manganese chloride solution, 2mol / L cobalt sulfate (dopant) solution, 5mol / L potassium hydroxide solution, add 200dm of potassium hydroxide solution per cubic meter 3 Concentrated ammonia. at 5m 3 Inject 200dm into the stirring constant temperature titanium-lined reactor 3 Pure water, 50dm 3 Concentrated ammonia water, start stirring, set the reaction temperature to 35°C, use a real-time pH automatic control device to control the injection of potassium hydroxide (containing ammonia water), and control the pH range of the system between 8 and 11. Use a metering pump to inject the manganese chloride and cobalt sulfate solutions into the reactor at multiple points, and control the flow rate to 20dm respectively 3 min -1 and 2dm 3 min -1 , Stop injecting after 1.5h. After continuing to react for 3h, the material was discharged. Use a filter press to filter, fully press dry, wash the precipitate with pure water ...

Embodiment 3

[0038] Prepare the following aqueous solutions for use: 0.5 mol / L manganese nitrate solution, 0.1 mol / L nickel sulfate (dopant) solution, 1 mol / L sodium carbonate solution. at 0.1m 3 Inject 10dm into the stirring constant temperature polytetrafluoroethylene lined reactor 3 Pure water, 0.5dm 3Concentrated ammonia water, start stirring, and set the reaction temperature to 52°C. Use a metering pump to inject manganese nitrate, nickel sulfate and sodium carbonate solutions into the reactor at multiple points, and control the flow rate to 1dm respectively 3 min -1 、0.02dm 3 min -1 and 1.2dm 3 min -1 , Stop injecting after 0.5h. After continuing to react for 0.5h, the material was discharged. Use a centrifugal washing machine to filter and wash, and the solid matter is air-dried at 140° C. for 12 hours. Measure the manganese content of the obtained powder, stir and disperse the powder obtained in the previous step with an appropriate amount of benzene in the reactor, add t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com