Method for treating waste hydrochloric acid containing lead, zinc and ferrum

A treatment method and technology for waste hydrochloric acid, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. To avoid heavy metal pollution, the process is simple and practical, and the effect of removing lead is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

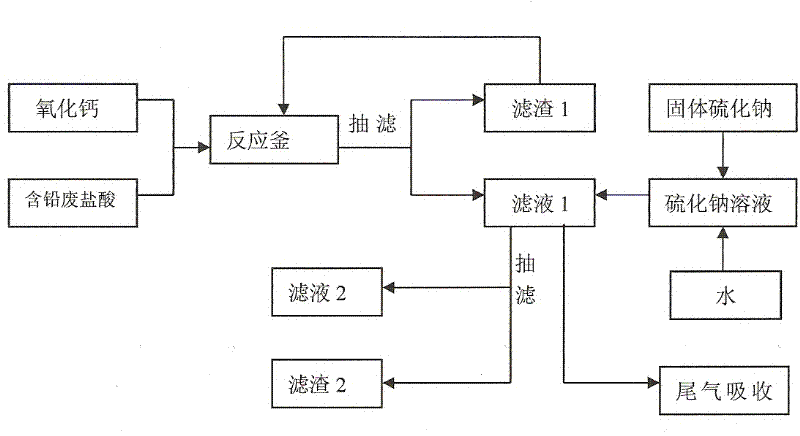

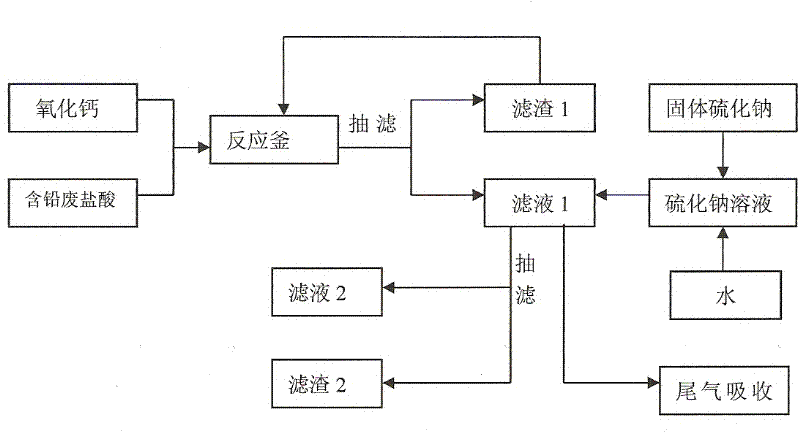

[0015] The treatment method of waste hydrochloric acid containing lead, zinc and iron described in this example takes the treatment of waste hydrochloric acid in the steel wire rope industry as an example, as figure 1 As shown, through the following process flow:

[0016] (1) After starting the tail gas absorption system (10% NaOH solution), add a certain amount of calcium oxide into the waste hydrochloric acid solution for reaction, preferably the pH of the filtrate after the reaction is about 0.5-4.5. The main chemical reactions are:

[0017] CaO+H 2 O→Ca(OH) 2

[0018] Ca(OH) 2 +2HCl→CaCl 2 +2H 2 o

[0019] CaCO 3 +2HCl→CaCl 2 +H 2 O+CO 2 ↑

[0020] (2) The filtrate is pumped into the reactor and left for the next reaction, and the filter residue (the filter residue is a small amount of lead, zinc, iron hydroxide precipitates and calcium oxide impurities) is used for the next batch of reactions.

[0021] (3) After opening the reactor and stirring, add the confi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com