Stabilizing material, and preparation method and application thereof

A technology for stabilizing materials and uses, applied in the field of stabilizing materials and their preparation, can solve problems such as soil, surface and groundwater pollution, plant and human health hazards, and small processing capacity, and achieve convenient use, controllable curing time and strength, The effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

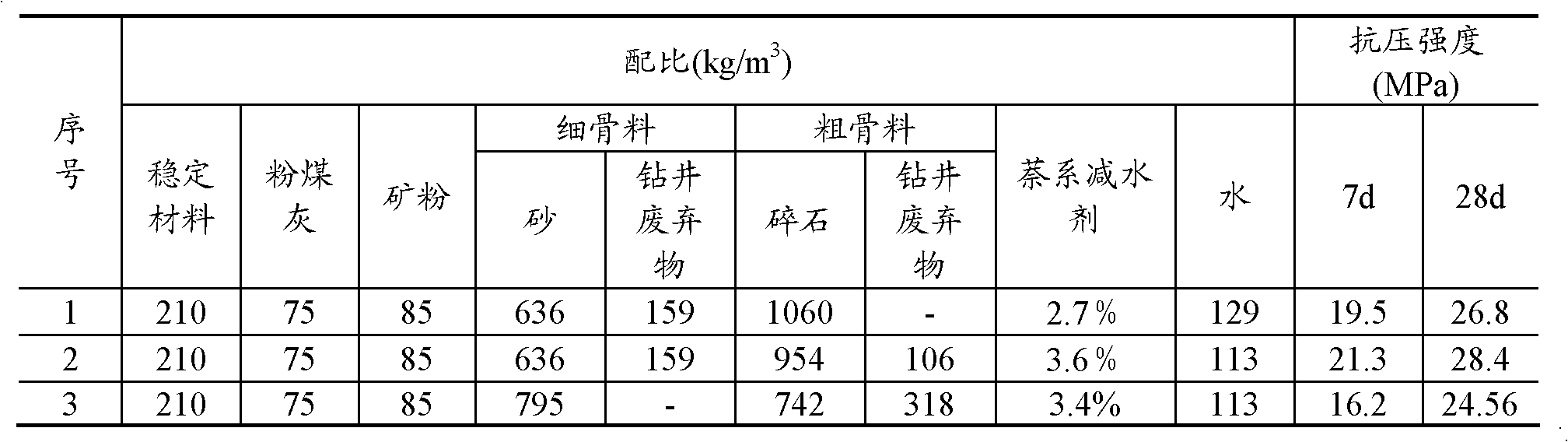

Embodiment 1

[0027] First, 2 kg of calcined phosphogypsum powder and 3 kg of fly ash are mixed to form the core material. Then 70 kilograms of sulphoaluminate cement and 15 kilograms of ordinary Portland cement are mixed uniformly, and then added into a ball mill together with 10 kilograms of quicklime and the above-mentioned 5 kilograms of core material and mixed to obtain a stable material.

[0028] Performance evaluation: After adding 8wt% of the above-mentioned stabilizing materials to the drilling waste to be solidified and fully mixed, the mixed waste loses fluidity, placed and cured for 7 days, and its cementation strength is 0.8Mpa.

Embodiment 2

[0030] First mix 5 kg of calcined phosphogypsum powder, 1 kg of naphthalene-based water reducer and 4 kg of fly ash to make the core material. Then 70 kilograms of sulphoaluminate cement and 10 kilograms of ordinary portland cement are mixed evenly, and then together with 5 kilograms of quicklime and the above-mentioned 10 kilograms of core material, they are added into a ball mill and mixed to obtain a stable material.

[0031] Performance evaluation: After adding 15wt% of the stabilizing material to the drilling waste to be solidified and fully mixed, after the mixed waste loses fluidity, it is placed and cured for 7 days, and its cementation strength is 1.5Mpa.

Embodiment 3

[0033] First mix 5 kg of calcined phosphogypsum powder, 1 kg of naphthalene-based water reducer and 4 kg of fly ash to make the core material. Then 75 kilograms of sulphoaluminate cement and 5 kilograms of ordinary Portland cement are mixed uniformly, and then added into a ball mill together with 10 kilograms of quicklime and the above-mentioned 10 kilograms of core material and mixed to obtain a stable material.

[0034] Performance evaluation: After adding 20wt% of the stabilizing material to the drilling waste to be solidified and fully mixed, after the mixed waste loses fluidity, it is placed and cured for 7 days, and its bonding strength is 2.1Mpa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com